Heat treatment method and system of SAE1065 steel wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The heat treatment method of the SAE1065 steel wire of the present invention includes loading the steel wire at a temperature of 300±25° C., uniformly elongating the steel wire at a speed of 0.92 to 1.4 mm / min, and cooling it to room temperature in air for 5 minutes, and unloading to obtain the heat-treated SAE1065 steel wire.

[0023] Preferably, the temperature when loading the steel wire is 300±10°C.

[0024] Preferably, the uniform elongation speed of the steel wire is 1 mm / min.

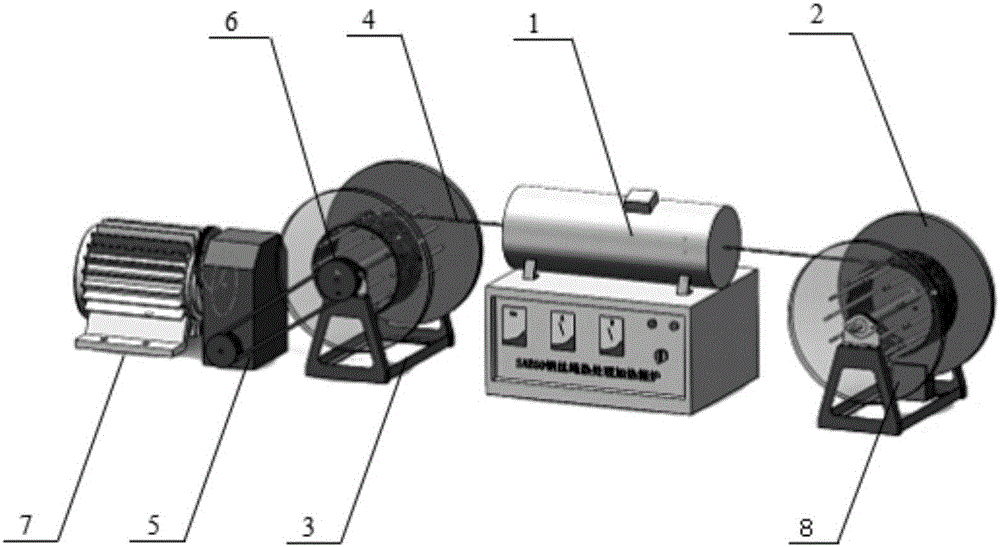

[0025] The heat treatment system for SAE1065 steel wire of the present invention comprises a heating furnace 1, a raw material steel wire reel 2 and a finished steel wire reel 3 are respectively arranged on both sides of the heating furnace 1, the SAE1065 steel wire 4 passes through the heating furnace 1, and the two ends are respectively wound on the raw material steel wire On the reel 2 and the finished steel wire reel 3 , the finished steel wire reel 3 is connected with the power devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com