Spinning tool and metal surface spinning strengthening method

A technology for spinning tools and metal surfaces, applied in the field of spinning tools and metal surface spinning strengthening, can solve the problem of unsatisfactory surface strengthening effect of high-strength metal materials, poor surface metal grain refinement effect, and rough surface of metal components, etc. problem, to achieve the effect of being conducive to promotion, improving bending fatigue life, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A spinning tool, such as Figure 4 As shown, the cutter adopts a cylindrical structure, the cutter head adopts an arc surface geometric structure, the radius of curvature of the arc surface is 2mm, and four openings are arranged on the cutter head, as Figure 5 As shown, the opening positions are evenly distributed along the circumferential direction. The role of setting the opening is to throw away a small amount of metal fines generated by wear from the center of the tool, and at the same time accelerate the cooling of the tool, reducing the damage to the tool caused by a small amount of metal chips and the temperature generated by processing.

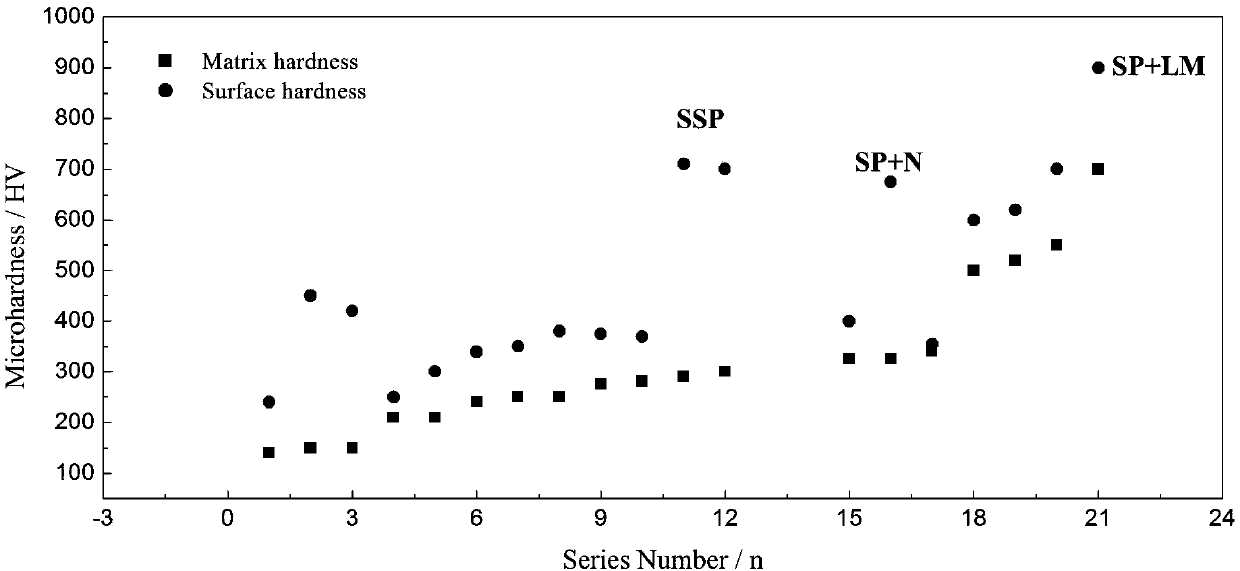

[0062] The material of the spinning tool is W18Cr4V high-speed tool steel, and the metal matrix to be processed is 60Si2Mn spring steel with an average microhardness of 480HV and a tensile strength of 1600MPa.

[0063] Using the above-mentioned spinning tool, the method of spinning and strengthening the surface of 60Si2Mn spr...

Embodiment 2

[0071] A spinning cutter, same as embodiment 1.

[0072] Using the above-mentioned spinning tool, the method of spinning and strengthening the surface of 60Si2Mn spring steel is as follows:

[0073] Step 1: Remove the oil stain and rust layer on the surface of the 60Si2Mn spring steel by sandblasting;

[0074] Step 2: Make the spinning tool contact with the surface of 60Si2Mn spring steel, and the axis of the spinning tool is perpendicular to the surface of the processed 60Si2Mn spring steel;

[0075] Step 3: Use a milling machine to rotate the spinning tool quickly, and the tool rotates relative to the 60Si2Mn spring steel to apply shear stress to the surface of the 60Si2Mn spring steel, that is, to introduce residual compressive stress, to achieve grain refinement on the surface layer, and to achieve work hardening. Gradient microstructure, stop the operation when the processing area is reached; among them, the pressing amount of the spinning tool is 200 μm, the feeding speed...

Embodiment 3

[0082] A spinning tool, such as Figure 6 As shown, the tool adopts a cylindrical structure, and four metal hemispheres are arranged on the bottom surface of the cylinder of the spinning tool. The diameter of the metal hemispheres is 3 mm, and the positions of the metal hemispheres are evenly distributed along the circumferential direction. A plurality of metal hemispheres are evenly distributed on the plane, and the metal hemispheres are used to introduce residual compressive stress to the surface of the processed metal component and realize grain refinement.

[0083] The hardness of the spinning tool is higher than the initial surface hardness of the metal component to be processed.

[0084] The material of the spinning tool is a ceramic material, and the metal matrix to be processed is 30CrNi2.5MoV steel with an average microhardness of 330HV and a tensile strength of 1000MPa.

[0085] Using the above-mentioned spinning tool, the method of spinning and strengthening the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com