Wind driven generator yawing device with locking function

A wind turbine and locking mechanism technology, applied in wind turbines, wind power generation, engines, etc., can solve the problems of increasing the energy consumption rate of wind turbines, complicated processing technology of large-diameter bearings, and increasing the cost of wind turbines. Achieve the effect of saving energy consumption, protecting the safety of the fan, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The embodiment is based on the specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. However, the protection scope of the claims of the present application is not limited to the description of the following embodiments.

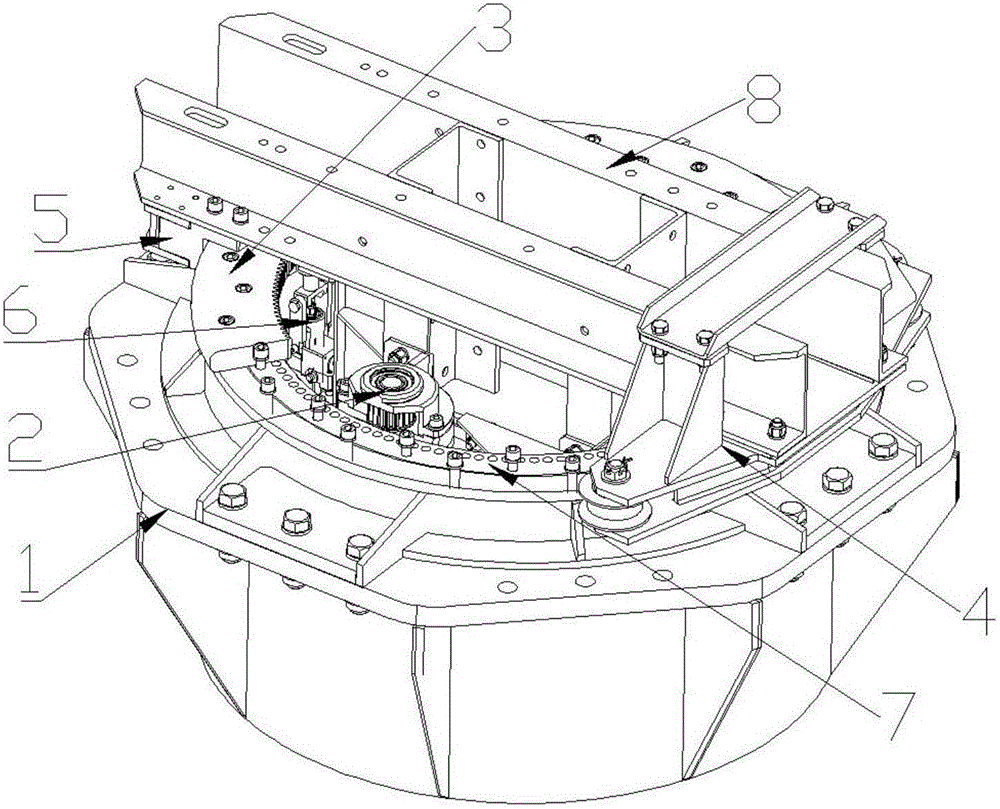

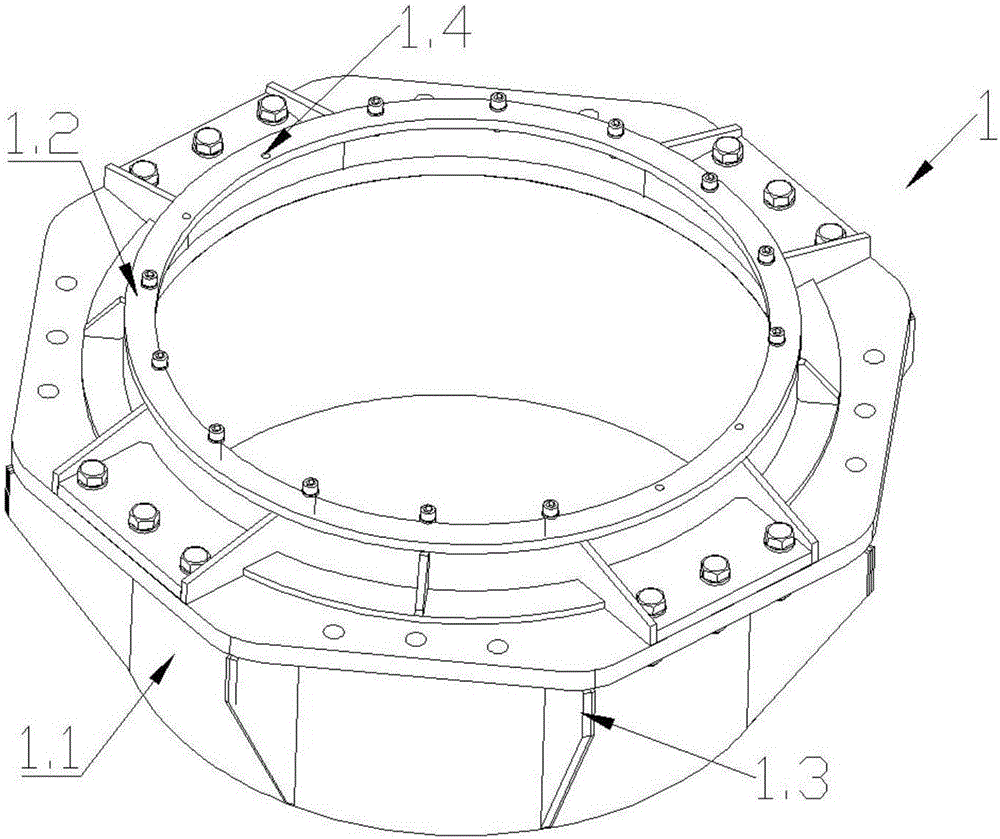

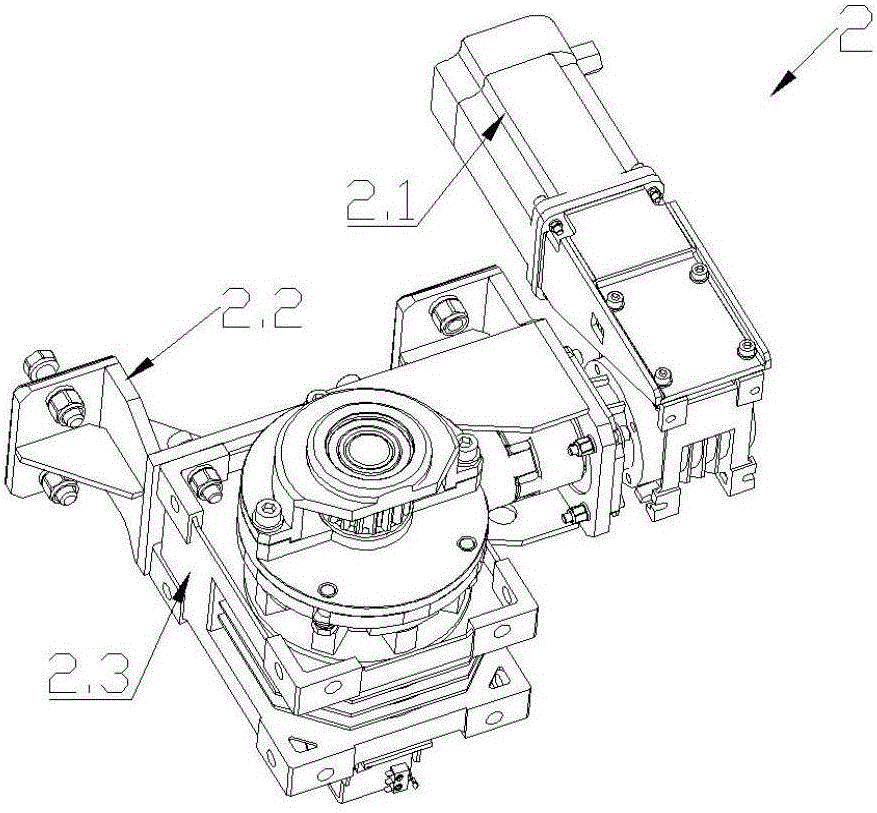

[0029] The wind power generator yaw device with locking function of the present invention (referred to as yaw device, see Figure 1-9 ) includes a tower mechanism 1, a yaw driving mechanism 2, a transmission inner ring gear 3, a ring gear matching supporting wheel frame 4, a ring gear matching adjusting wheel frame 5, a locking mechanism 6, a locking chuck 7 and a nacelle supporting frame 8 ;

[0030] Described nacelle bracing frame 8 (referring to Figure 9 ) includes engine room support frame crossbeam 8.1, engine room support frame conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com