Real-time monitoring and controlling method for friction torque of dry clutch

A dry clutch, friction torque technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problems of low friction torque accuracy, friction torque calculation error, weakened monitoring effect, etc., and achieve a simple real-time monitoring model. , to ensure the control effect, to achieve the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

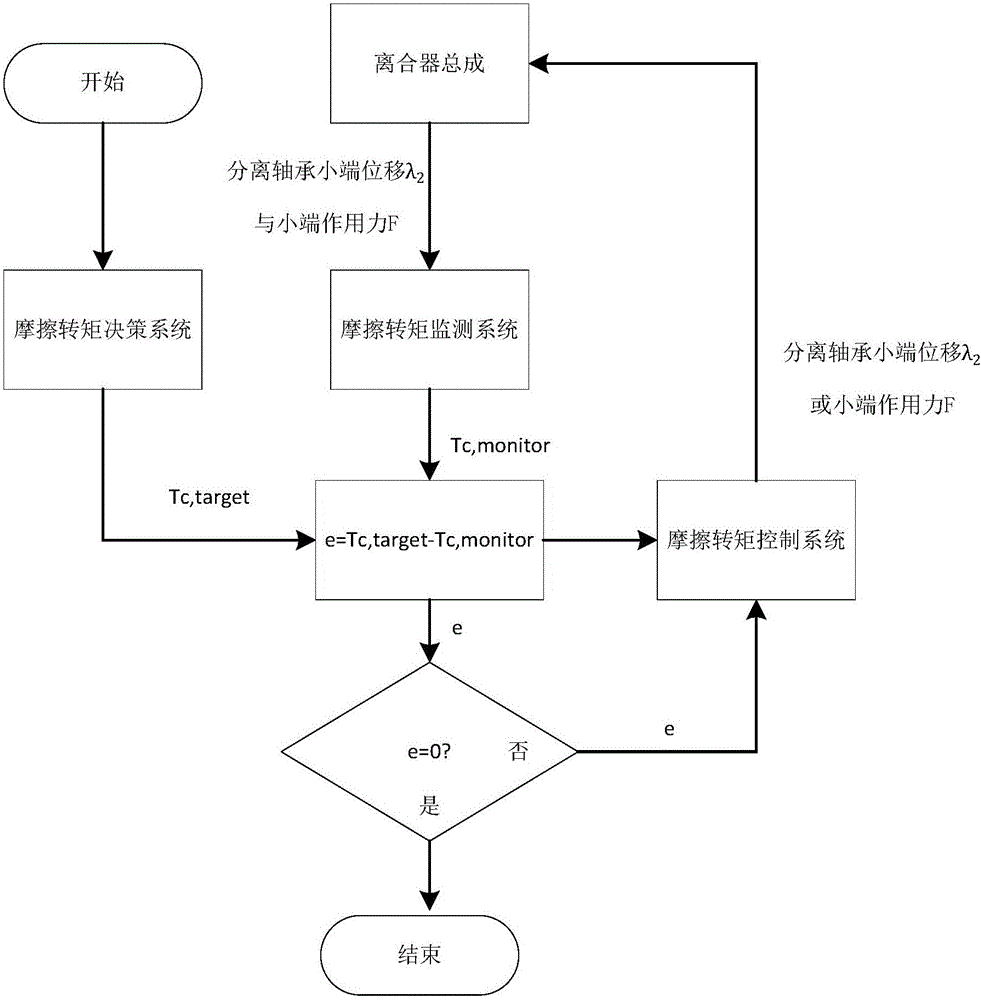

[0032] Working condition description: Take the situation where the road surface slope increases while the car is running as an example.

[0033] Application object: Take the vehicle installed with electronically controlled hydraulic automatic transmission as an example.

[0034] The operation process of the torque real-time monitoring system is as follows:

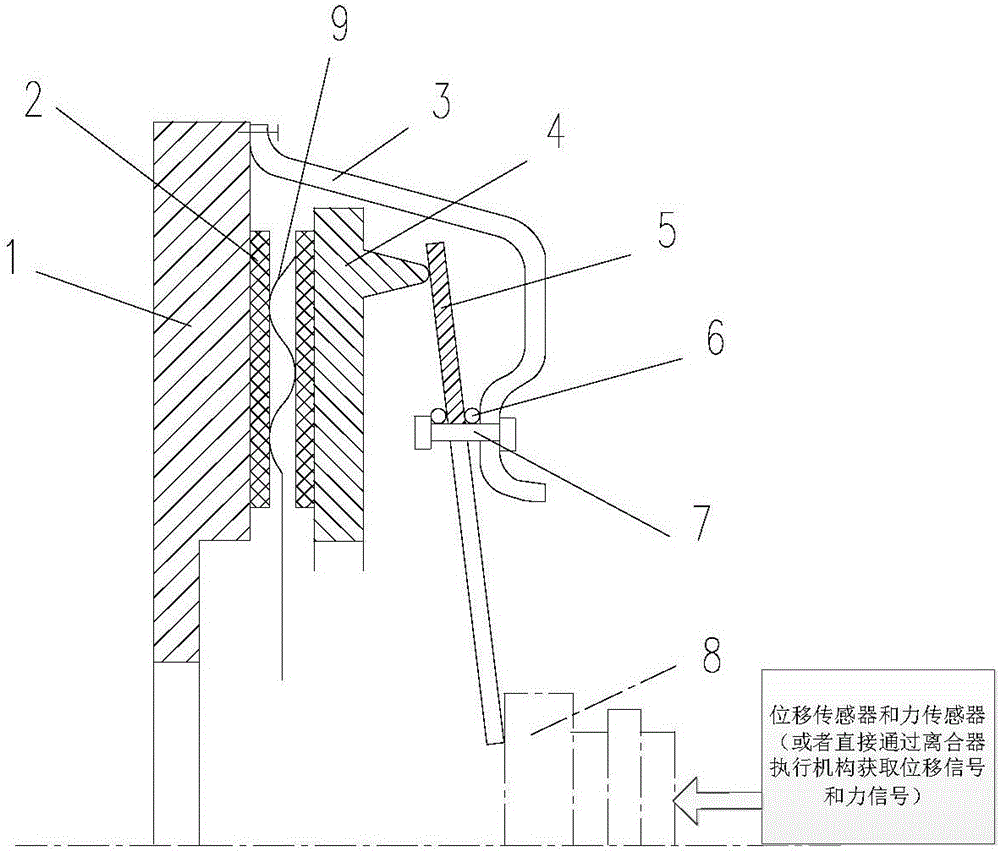

[0035] 1. The displacement sensor and force sensor at the clutch release bearing send the displacement signal and force signal of the small end of the diaphragm spring to the TCU of the transmission in real time through the CAN bus (or the electromagnetic valve of the electro-hydraulic clutch actuator sends the current signal through the CAN bus Send it to the TCU of the transmission in real time, and the TCU calculates the displacement signal and force signal of the small end of the diaphragm spring according to the internal algorithm).

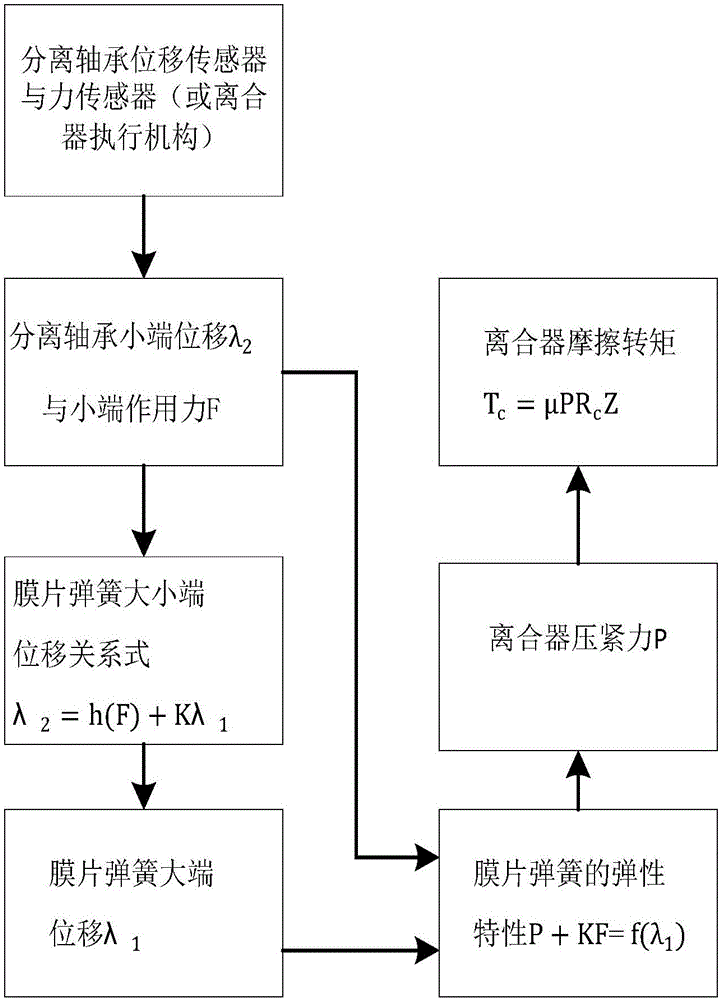

[0036] 2. The displacement relationship between the large and small ends of the diaph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com