Method for detecting diameter of rotary jet grouting pile

A technology of transmission method and rotary grouting pile, which is applied in the field of measurement and testing, can solve the problems that the diameter of the rotary grouting pile is difficult to control, difficult to detect, and there is no detection of the diameter of the rotary grouting pile, so as to save money and cost investment, and the investment is not damaged , The effect of simple detection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] As shown in the figure, the method for detecting the pile diameter of the rotary grouting pile by the acoustic wave transmission method in the present invention comprises the following steps:

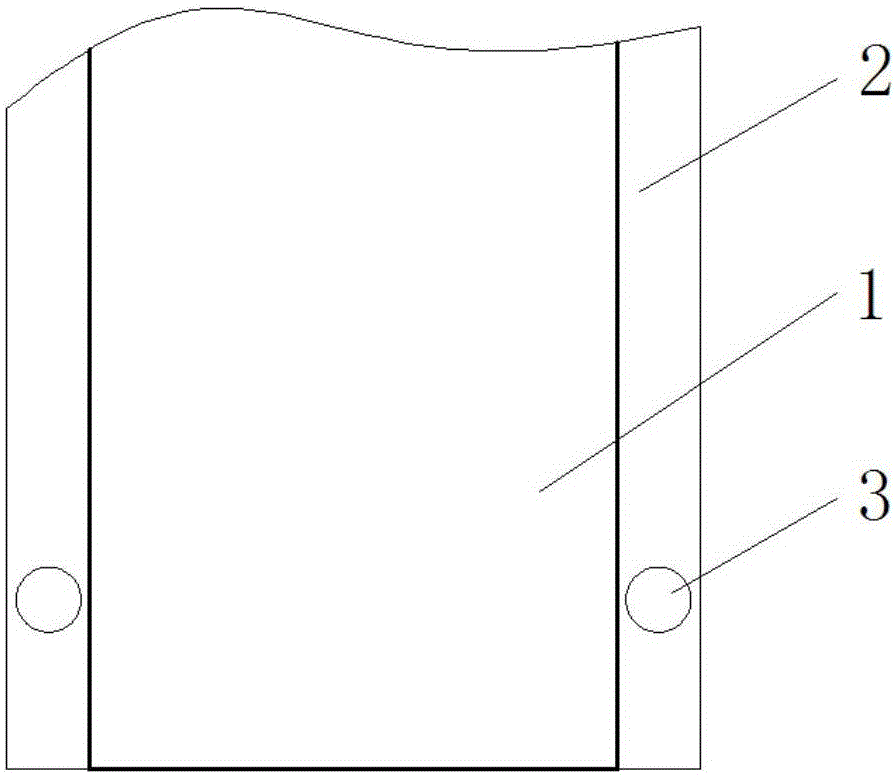

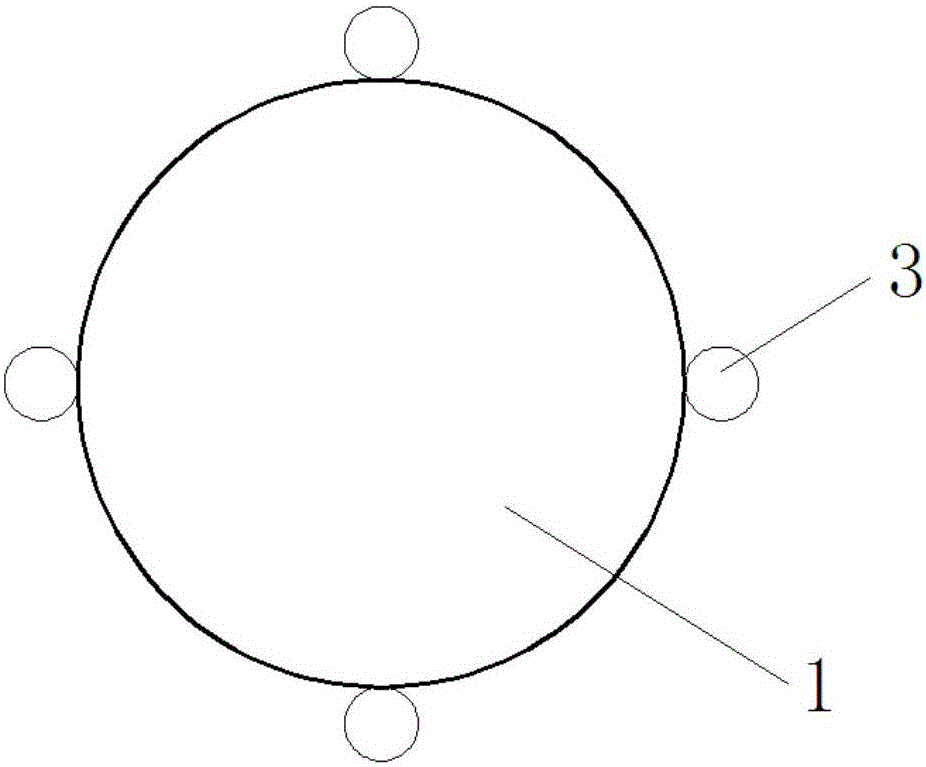

[0023] 1) Determine the geological conditions of the pile to be tested, and use the pile outer hole transmission method to evenly arrange a number of acoustic tubes 2 on the outside of the pile to be tested and keep the acoustic tubes 2 in parallel. The transducers 3 should be positioned at the same elevation; because sound waves attenuate extremely quickly in the soil, the acoustic measuring tube 2 should be placed close to the pile without damaging the integrity of the jet grouting pile to be tested.

[0024] 2) Select an easy-to-measure point on the pile to be measured as the reference point, use the acoustic wave transmission method to mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com