Powder material heat insulation effect evaluation device and application method thereof

A heat insulation effect and powder material technology, which is applied in the field of powder material heat insulation effect evaluation device, can solve the problems of not easy to carry, long test cycle, unstable constant temperature environment setting, etc., to reduce the error of evaluation results and test accuracy Accurate, stable and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

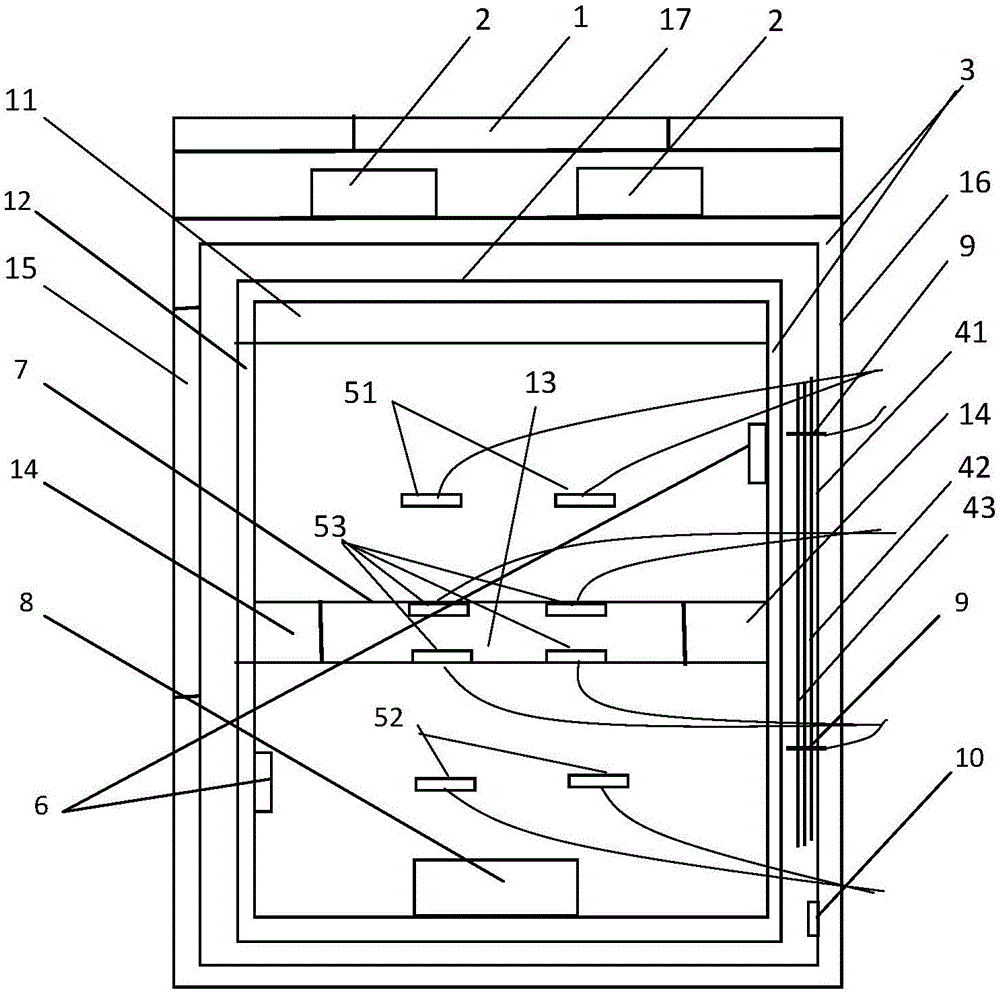

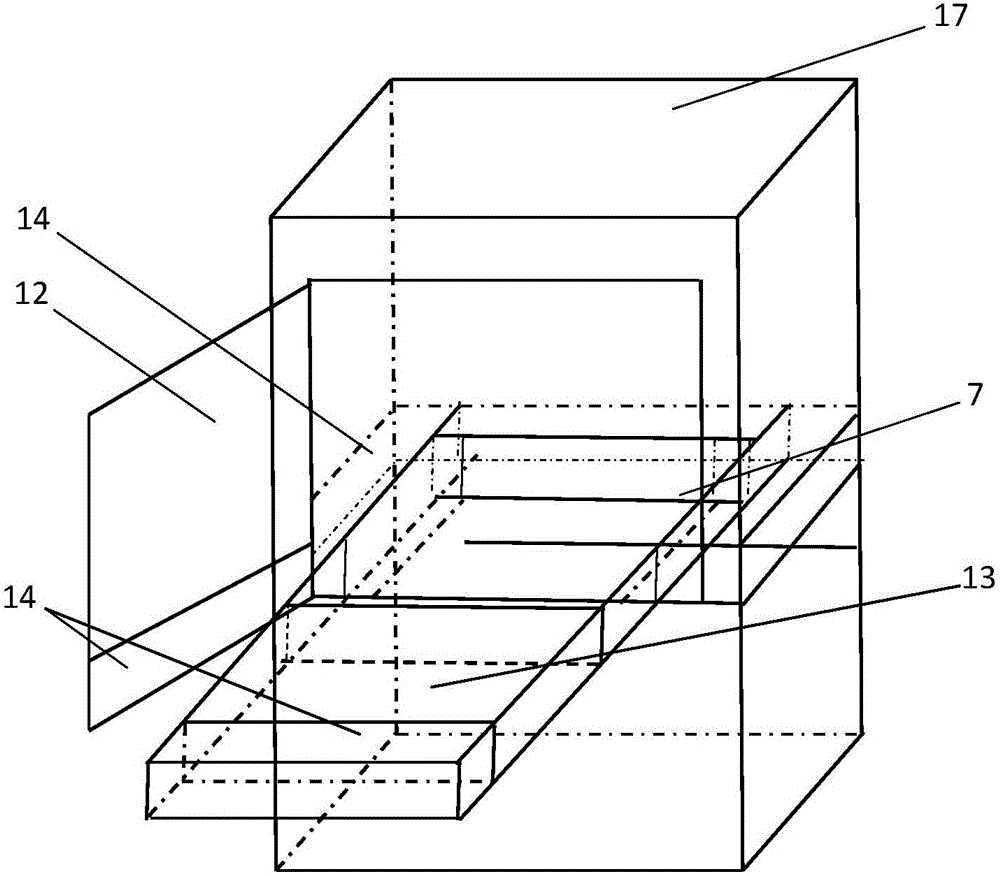

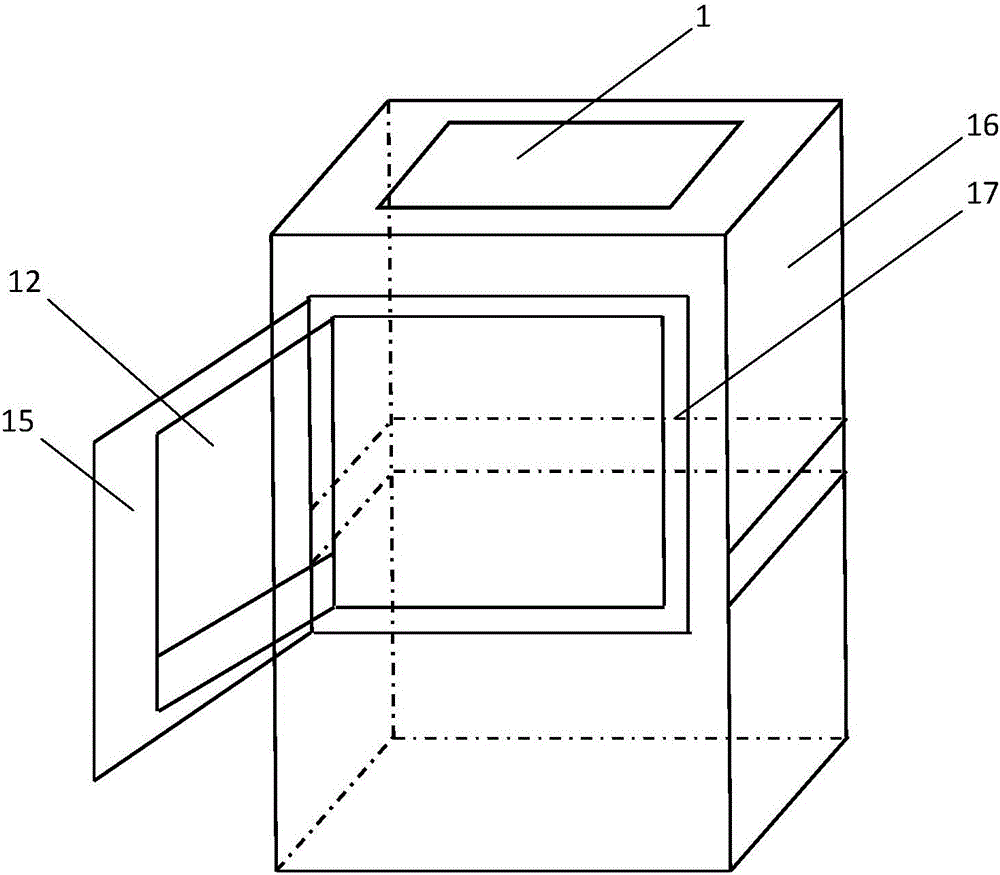

[0061] The composition of the powder material heat insulation effect evaluation device of this embodiment is as follows: figure 1 As shown in the embodiment, the middle position of the upper box part of the test box 17 is equipped with 2 temperature sensors 51 on the upper part of the test box for testing the internal air temperature of the upper box, and the middle position of the lower box part of the test box 17 2 temperature sensors 52 of the lower part of the test box for testing the inner air temperature of the lower box are installed, and 2 sample tank temperature sensors 53 are respectively installed on the upper and lower sides of the inside of the sample tank 13; the heat dissipation element 6 and the refrigeration temperature control element The power supply of 8 adopts a switching power supply and is placed in the lower box. The size of the thermostatic box 16 is 400mm×400mm×600mm. The sample tank 13 is made of copper and its size is 150mm×150mm×10mm. The temperatur...

Embodiment 2

[0084] In the heat insulation effect evaluation device for powder materials of this embodiment, except that the middle position of the upper box part of the test box 17 is equipped with 4 temperature sensors 51 on the upper part of the test box for testing the air temperature inside the upper box, the test box The middle position of the lower box body part of 17 is equipped with 4 test box lower part temperature sensors 52 for testing the air temperature inside the lower box body, and 4 sample tank temperature sensors 53 are respectively installed on the upper and lower sides of the inside of the sample tank 13, so The size of the incubator 16 is 500mm × 500mm × 700mm, the sample tank 13 is made of aluminum, and its size is 200mm × 200mm × 18mm, the thermal resistance that the temperature sensors all adopt is platinum resistance Pt1000, other same Example 1.

[0085] The method of using the heat insulation effect evaluation device for powder materials in this embodiment is use...

Embodiment 3

[0107] In the heat insulation effect evaluation device for powder materials of this embodiment, except that the middle position of the upper box part of the test box 17 is equipped with 6 temperature sensors 51 on the upper part of the test box for testing the air temperature inside the upper box, the test box The middle position of the lower box body part of 17 is equipped with 6 test box lower part temperature sensors 52 for testing the air temperature inside the lower box body, and 4 sample tank temperature sensors 53 are respectively installed on the upper and lower sides of the inside of the sample tank 13, so The size of the incubator 16 is 600 mm × 600 mm × 800 mm, the sample tank 13 is made of iron, and its size is 250 mm × 250 mm × 25 mm, other is the same as the embodiment 1.

[0108] The method of using the heat insulation effect evaluation device for powder materials in this embodiment is used to evaluate the heat insulation effect of a mixed powder material. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com