Heat error measuring system of whole workbench of numerical control machine tool and measuring method of system

A technology of numerical control machine tools and measurement systems, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of less research on thermal errors, differences in thermal errors, and lack of publications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

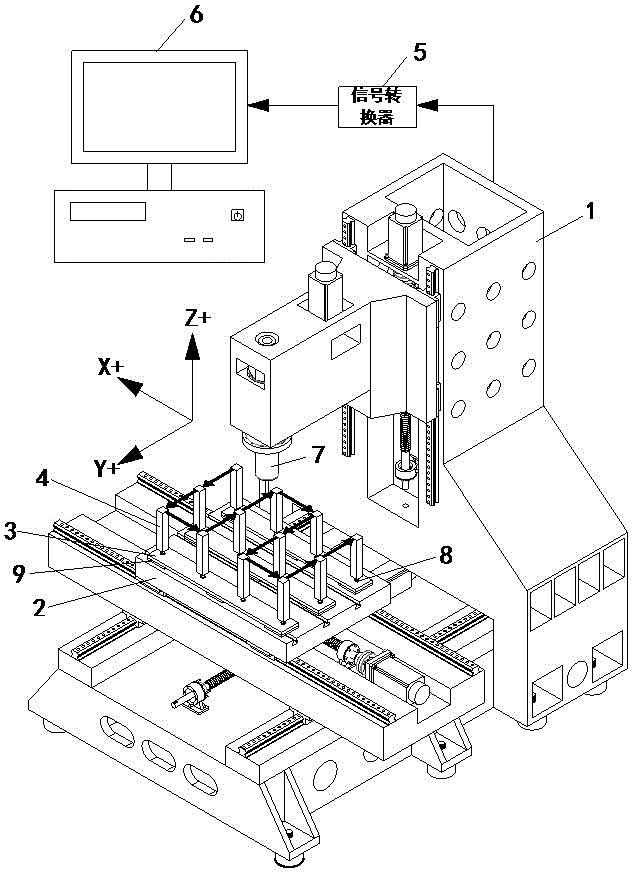

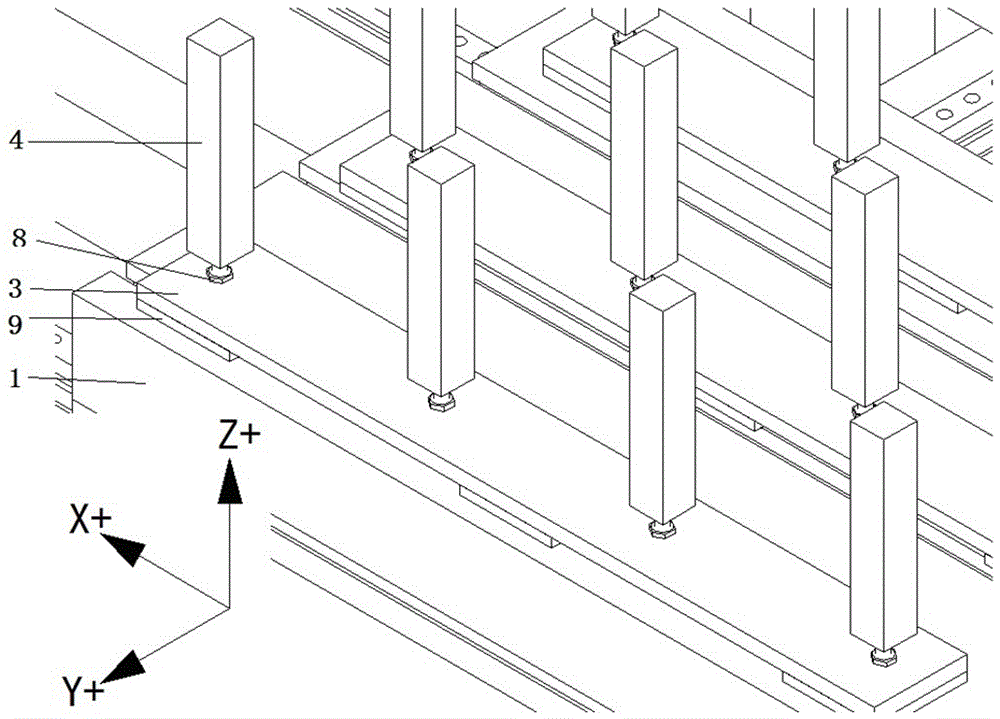

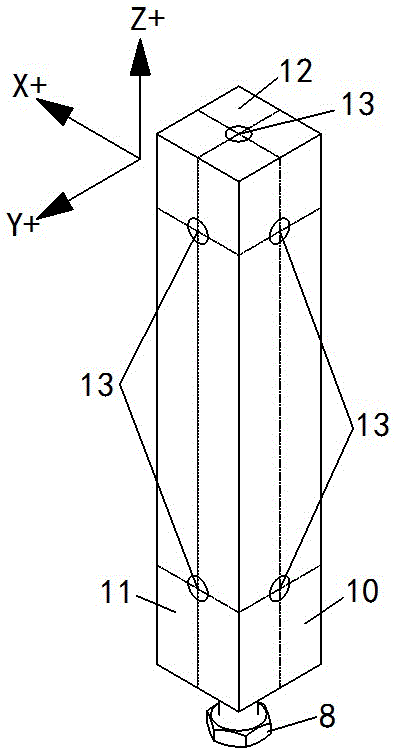

[0033] Such as figure 1 As shown, a thermal error measurement system for a full workbench of a CNC machine tool includes a positioning plate 3 adsorbed on the workbench 2 of the CNC machine tool, and a plurality of cuboid standard parts 4 are uniformly installed on the positioning plate 3. The PMC module I / O port of the system is connected with the signal converter 5, and the signal converter 5 communicates bidirectionally with the computer 6, and the probe 7 is installed at the tool position of the numerically controlled machine tool 1, the cuboid standard part 4, the probe, The numerical control machine tool 1, the signal converter 5 and the computer 6 form a thermal error measurement system. The measuring head 7 measures the thermal error by touching the surfaces of each cuboid standard part 4 sequentially according to a certain path, such as Figure 5 In the S-shaped path shown, the measurement data is output to the I / O port through the PMC module of the numerical control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com