Anti-explosion long-service-life piezoresistor

A technology of varistors and varistors, applied in varistors, resistors, resistor components, etc., can solve problems such as local high temperature, ignition of coating layers, electrical fires, etc., and prolong service life , Improve the effect of surge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

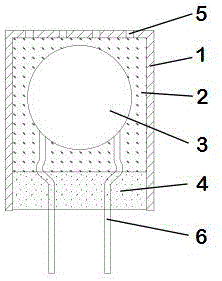

[0026] Such as Figure 1~2 As shown, the long-life piezoresistor with explosion-proof function in this embodiment has a housing 1 and an ordinary coating type piezoresistor 3 filled in the housing 1, and the ordinary coating type piezoresistor 3 and the housing 1 The cavity between them is filled with the buffer filler 2 as quartz sand, and the buffer filler 2 completely wraps the piezoresistor 3, and after the filling is completed, the opening at one end of the shell 1 is filled with the potting compound 4 to form a plugging layer, and at the same time The bent part of the lead wire 6 of the piezoresistor 3 is placed in the sealing layer formed by the potting compound 4, and the buffer filler 2 is quartz sand whose particle size is larger than the size of the circular through hole 5 provided on the shell 1, While ensuring that the air pressure inside the shell 1 is kept in harmony with the outside, it is also possible to avoid leakage of the internal granular buffer filler 2 ...

Embodiment 2

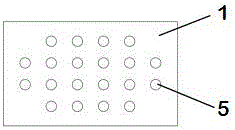

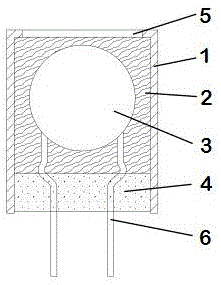

[0028] In this embodiment, the long-life piezoresistor with explosion-proof function has a casing 1 and an ordinary coating type piezoresistor 3 filled in the casing 1, and the gap between the ordinary coating type piezoresistor 3 and the casing 1 is The cavity is filled with ceramic particles with buffer filler 2, and the buffer filler 2 completely wraps the piezoresistor 3. After filling, the opening at one end of the shell 1 is filled with the potting compound 4 to form a sealing layer, and at the same time, the pressure sensitive The bent part of the lead wire 6 of the resistor 3 is placed in the sealing layer formed by the potting compound 4. The particle size of the buffer filler 2 is larger than the size of the strip-shaped through hole 5 provided on the housing 1, ensuring that the inside of the housing 1 While maintaining coordination with the external air pressure, it prevents the leakage of the internal particle-type cushion filling Tao 2.

[0029] The long-life var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com