Internal fuse protective dry self-healing high-voltage capacitor element

A technology of high-voltage capacitors and internal fuses, which is used in winding capacitors, fixed capacitor electrodes, and components of fixed capacitors, etc., can solve the problems of insufficient arcing distance, reduced reliability, and increased contacts, reducing the number of series connections, The effect of improving reliability and improving inrush current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

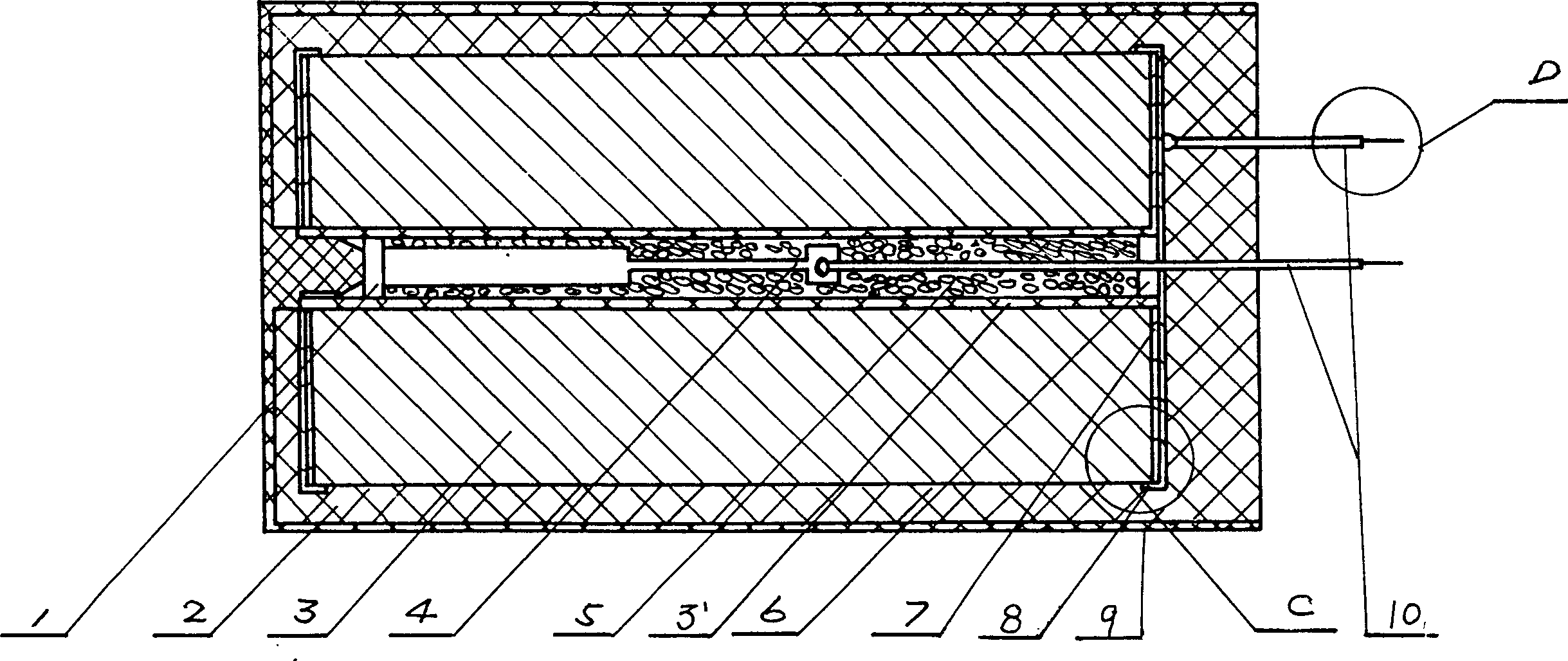

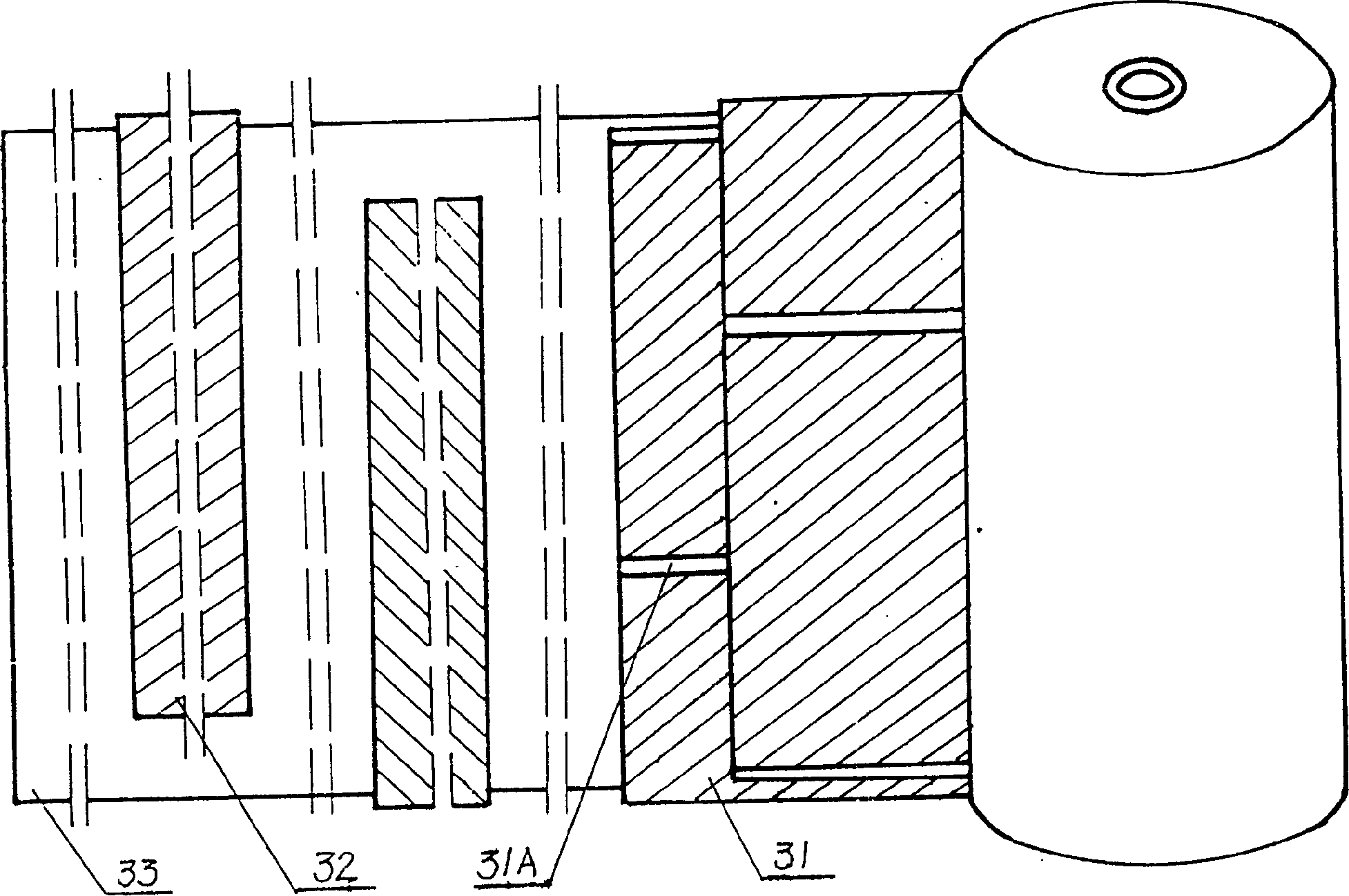

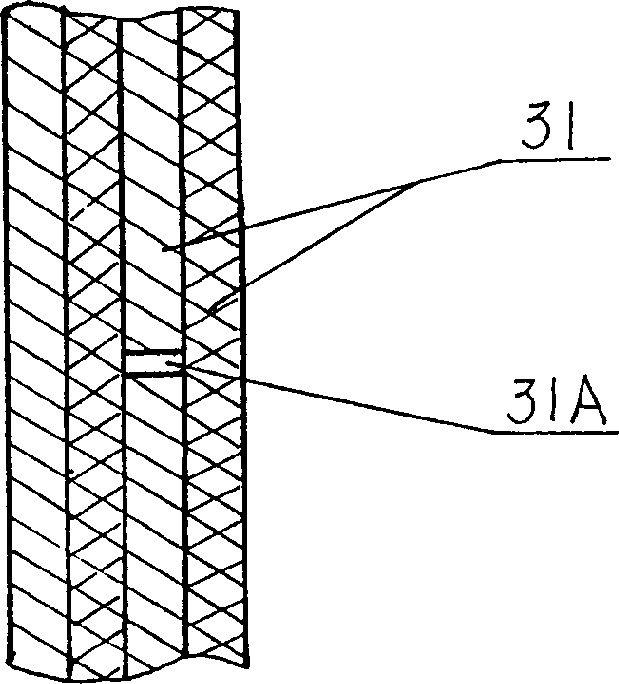

[0019] Such as figure 1 , 3 As shown in, 4, and 5, it has a frame 3, and there is a rolling element 3 on the frame 3'. The rolling element 3 includes a metalized film 31, an aluminum foil 32 and a polypropylene film 33, which respectively constitute the main capacitor And aluminum foil capacitors, in which there is an electrical isolation strip 31A on the plating layer of the metallized film 31, which makes the plating layer a two-stage electrode plate, and the adjacent plating layer forms two sets of electrode plates in series, thus forming two internal series Capacitor, an internal fuse 4 is placed in the frame 3'and filled with quartz sand 5. The two ends of the frame 3'are sealed with rubber pads 1, 6 and the internal fuse 4 is connected in series to an electrode of the component On the upper and lower end faces of the rolling element 3, there are gold spray layers 7 to connect the main capacitor and the aluminum foil capacitor in parallel, and lead out the electrode 10, and ...

Embodiment 2

[0021] Such as figure 1 , 2 As shown in, 4, and 5, it has a skeleton 3', on which there is a rolling element 3, said rolling element 3 includes a metalized film 31, an aluminum foil 32 and a polypropylene film 33, which respectively constitute the main capacitor And aluminum foil capacitors, where the plating on the adjacent metallized film 31 has a staggered electrical isolation strip 31A, so that the plating is a two-stage electrode plate, so that the plating on the adjacent metalized film 31 forms three sets of poles in series The inner fuse 4 is placed in the framework 3'and filled with quartz sand 5, and the two ends of the framework 3'are sealed with rubber pads 1, 6 to form three internal series capacitors. The wire 4 is connected in series to an electrode of the element. There are sprayed gold layers 7 on the upper and lower end faces of the rolled element 3, so that the main capacitor and the aluminum foil capacitor are connected in parallel, and the electrode lead 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com