Laminated varistor and producing method thereof

A technology of varistor and manufacturing method, applied in resistance manufacturing, varistor, resistor, etc., can solve problems such as poor solvent resistance, and achieve enhanced thermal shock resistance, improved mechanical properties, resistance consistency and resistance. Excellent solvent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

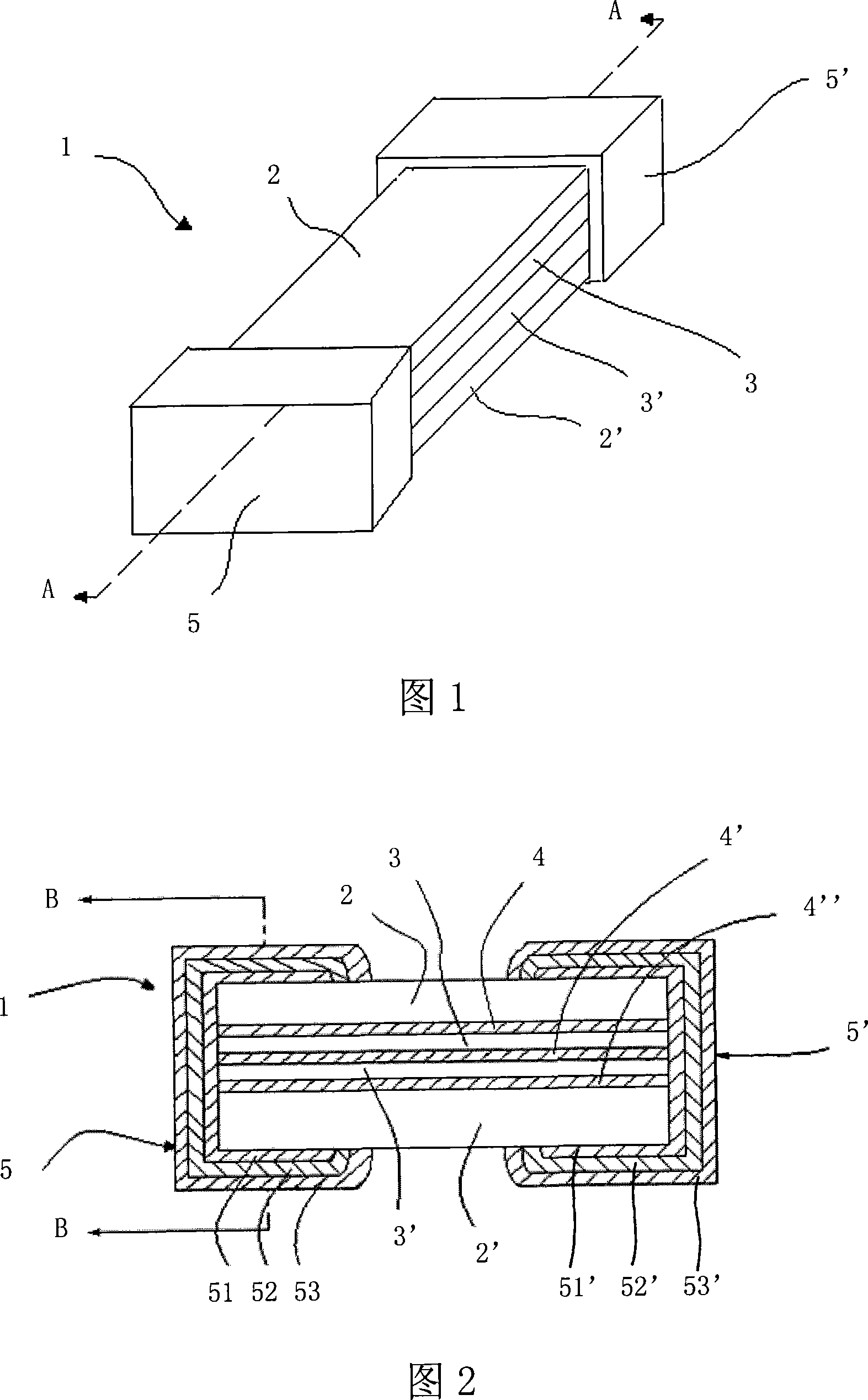

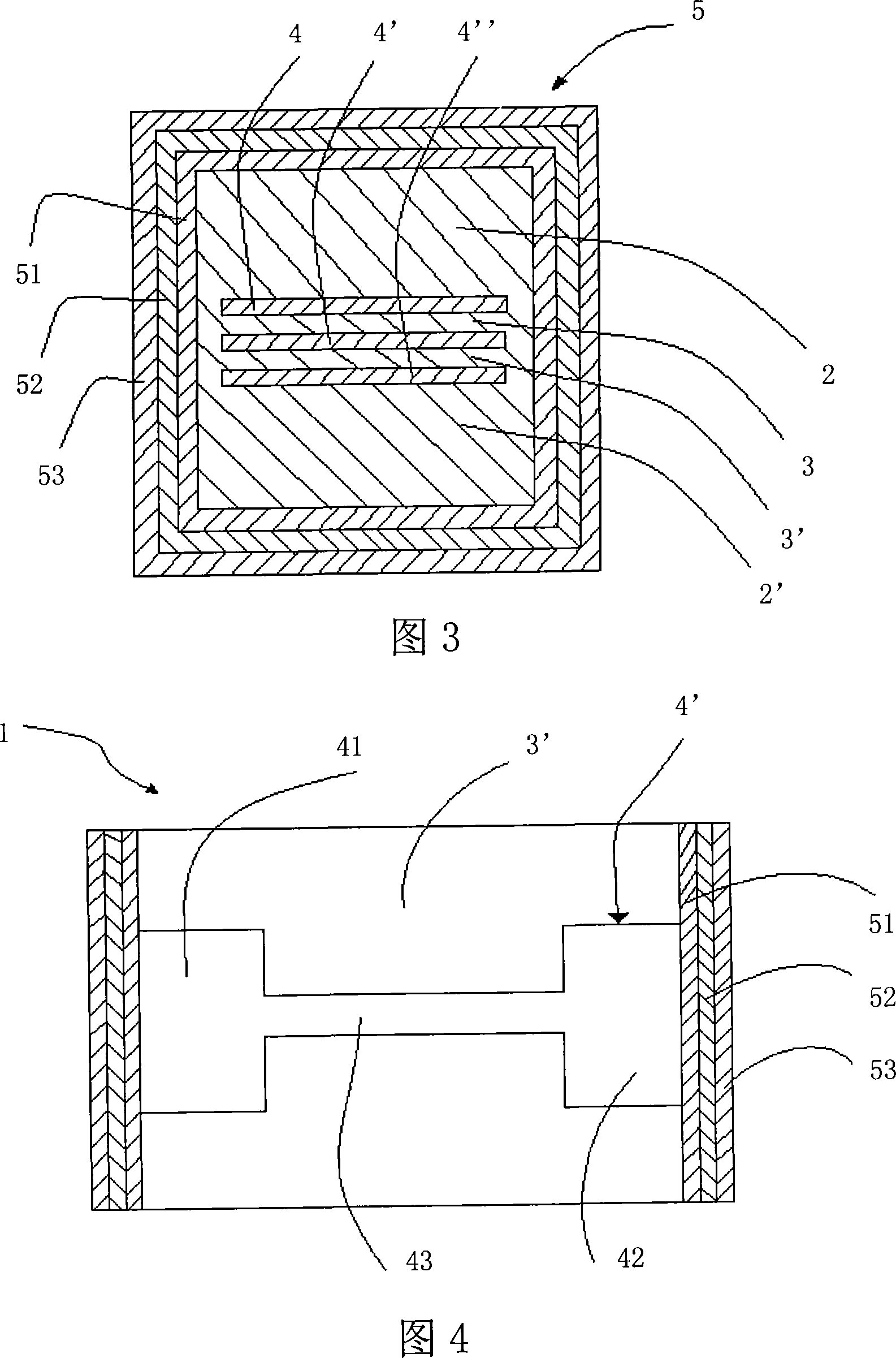

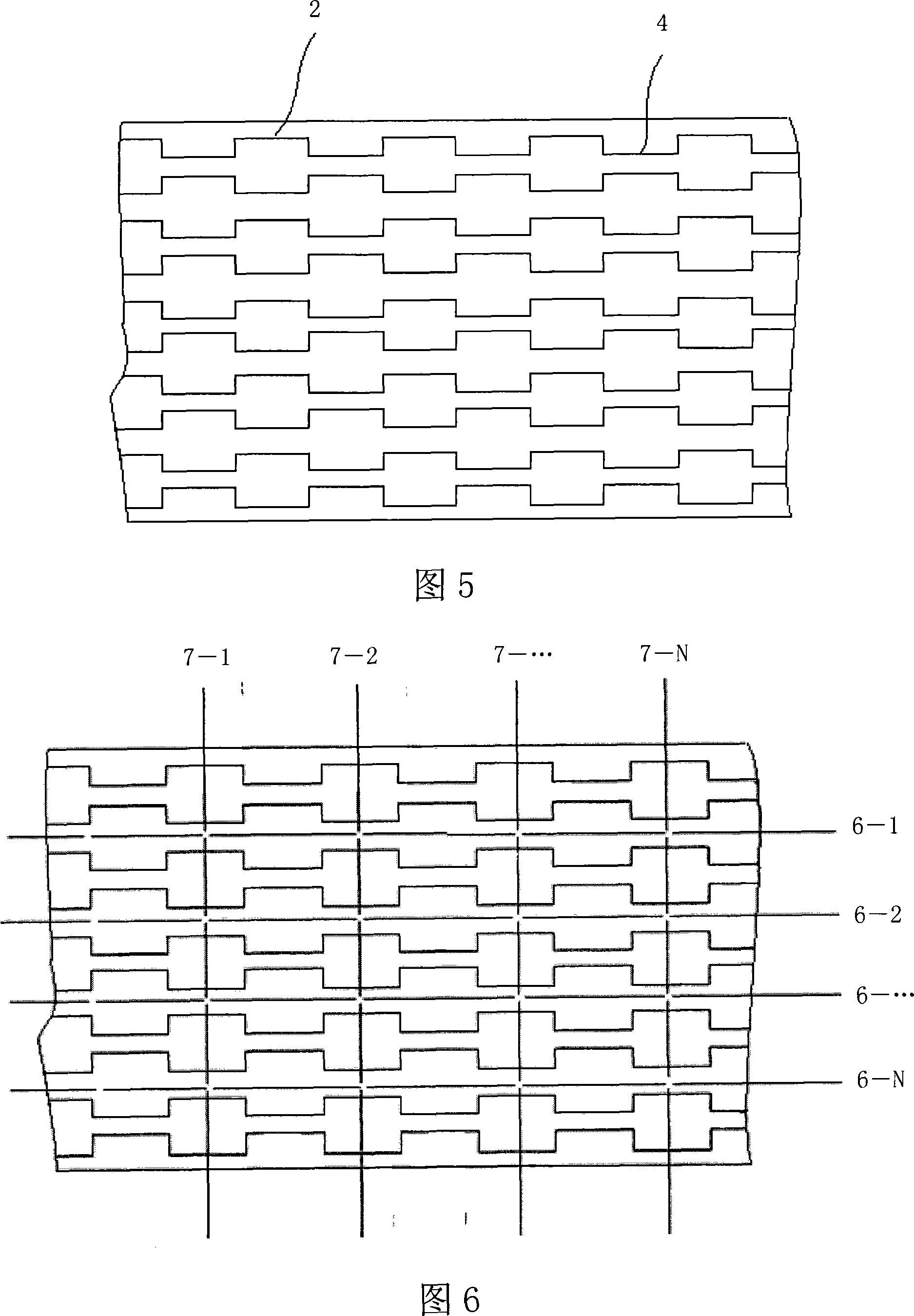

[0034] Please refer to Fig. 1 for a structural schematic diagram of the novel chip varistor of the present invention, Fig. 2 is a schematic diagram of a cross-sectional structure in the direction of A, Fig. 3 is a schematic diagram of a cross-sectional structure in the direction of B, and Fig. 4 is a top view of a ceramic-glass material layer with a piezoresistive film attached In the structural diagram, the proportions of each part are not strictly referred to in kind, but are enlarged for the convenience of explanation.

[0035] A new type of chip varistor 1 is composed of a glass-ceramic material layer, a varistor film and terminal electrodes covered at both ends, wherein the glass-ceramic material layer has four layers, which are used as the base layer, respectively It is the upper and lower surface base layers 2, 2' and the middle layer base layer 3, 3'. The inner surface of each base layer is attached with a piezoresistive film 4, 4', 4", and each layer is bonded together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com