A kind of impregnation method of solid electrolytic capacitor

A solid-state electrolysis and capacitor technology, applied in solid electrolytic capacitors, drying/dipping machines, etc., can solve the problems of conductive polymer chain breaking, affecting product performance, and inability to discharge gas effectively, so as to improve initial characteristics and improve surge resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

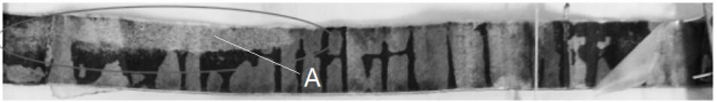

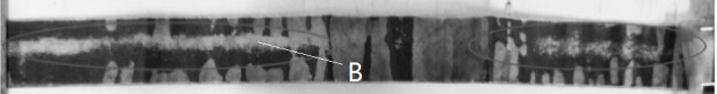

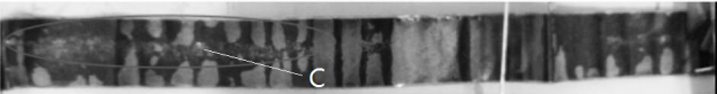

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of impregnation method of solid electrolytic capacitor, comprises the following steps:

[0028] (1) Weld and fix 10 groups of elements on the horizontal bar, make the elements face down vertically, and make the bottom of each group of elements on the same horizontal line.

[0029] (2) First install the horizontal bar with the element fixed on the frame; then, place it in the impregnation equipment with a vacuum degree of 50kpa, so that the element is located above the impregnation liquid; then, drive the element on the horizontal bar to move downward, Make the bottom of the element contact with the liquid surface of the impregnating liquid, and stay for 10s to carry out the first stage impregnating treatment;

[0030] (3) Drive the elements on the horizontal bar to move downward at a constant speed at a descending speed of 0.1mm / s, so that 1 / 2 the volume of elements is immersed in the impregnating liquid, and stay for 100s to carry out th...

Embodiment 2

[0033] This embodiment provides a kind of impregnation method of solid electrolytic capacitor, comprises the following steps:

[0034] (1) Weld and fix 30 groups of elements on the horizontal bar, make the elements face down vertically, and make the bottom of each group of elements on the same horizontal line.

[0035] (2) First install the horizontal bar with the element fixed on the frame; then, place it in the impregnation equipment with a vacuum degree of 90kpa, so that the element is located above the impregnation liquid; then, drive the element on the horizontal bar to move downward, Make the bottom of the element contact with the liquid surface of the impregnating liquid, and stay for 60s to carry out the first stage impregnating treatment;

[0036] (3) Drive the elements on the bar to move downward at a constant speed at a descending speed of 0.4mm / s, so that 1 / 2 volume of elements is immersed in the impregnating solution, and stay for 300s to carry out the second stag...

Embodiment 3

[0039] This embodiment provides a kind of impregnation method of solid electrolytic capacitor, comprises the following steps:

[0040] (1) Weld and fix 20 groups of elements on the horizontal bar, make the elements face down vertically, and make the bottom of each group of elements on the same horizontal line.

[0041] (2) First install the horizontal bar with the element fixed on the frame; then, place it in the impregnation equipment with a vacuum degree of 80kpa, so that the element is located above the impregnation liquid; then, drive the element on the horizontal bar to move downward, Make the bottom of the element contact with the liquid surface of the impregnating liquid, and stay for 30s to carry out the first stage impregnating treatment;

[0042] (3) Drive the elements on the horizontal bar to move downward at a constant speed at a descending speed of 0.3mm / s, so that 2 / 3 of the volume of elements is immersed in the impregnating liquid, and stay for 200s, and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com