360-degree light emitting LED device and 360-degree light emitting LED light source

A technology of LED devices and LED chips, which is applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve problems such as high thermal resistance, difficult control of product quality, difficulty in selection, use and processing of light conversion layers, and achieve product quality. High, easy to manufacture and material selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

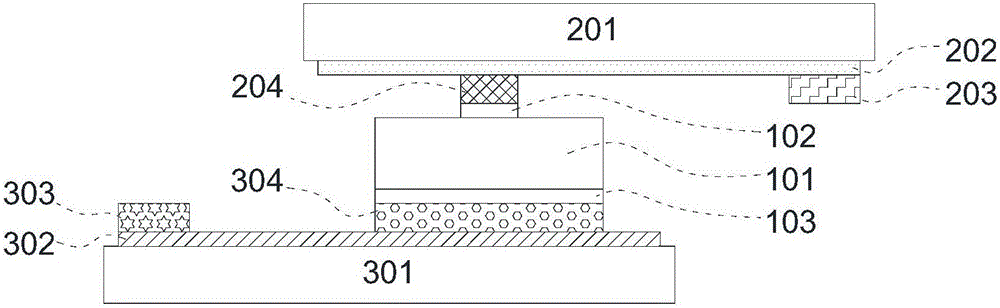

[0049] This embodiment is a typical scheme of single LED chip packaging, its structure is as follows image 3 Shown:

[0050] The LED chip 101 is a blue light LED chip with a vertical structure, and its luminous wavelength range is 440-470nm. The chip N electrode 102 and the chip P electrode 103 are respectively located at the upper and lower ends of the LED chip 101. The main material of the chip P electrode 103 is ITO transparent and conductive film. It should be noted that this embodiment schematically illustrates the situation of blue LED chips, and the present invention also includes various types of LED chips such as red light and green light, which are all equivalent protection scopes of the present invention.

[0051] Wherein, the main material of the transparent upper substrate 201 is sapphire, and a patterned first transparent conductive layer 202 is arranged on one surface thereof, and the main material of the first transparent conductive layer 202 is a graphene tr...

Embodiment 2

[0061] like Figure 4 As shown, this embodiment is another typical scheme of packaging a single LED chip. Its structure is as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the first external electrode 203 and the second external electrode 303 are improved:

[0062] The first external electrode 203 is changed to directly make a long first conductive circuit layer 205 on the transparent upper substrate 201 to connect with the first transparent conductive layer 202, and the first conductive circuit layer 205 acts as an external electrode and enhances electrical and thermal conductivity. The role of ability.

[0063] Similarly, the second external electrode 303 is changed to directly make a long second conductive line layer 305 on the transparent lower substrate 301 to connect with the second transparent conductive layer 302, and the second conductive line layer 305 acts as an external electrode and enhances The role of electrical and therm...

Embodiment 3

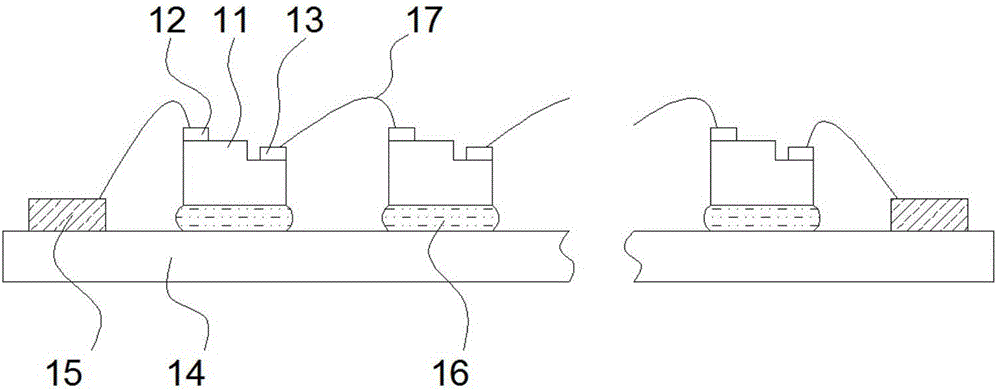

[0066] like Figure 5 As shown, this embodiment discloses that multiple LED chips are connected in series, and wrapped and packaged with fluorescent glue, so as to form an LED filament that can emit white light.

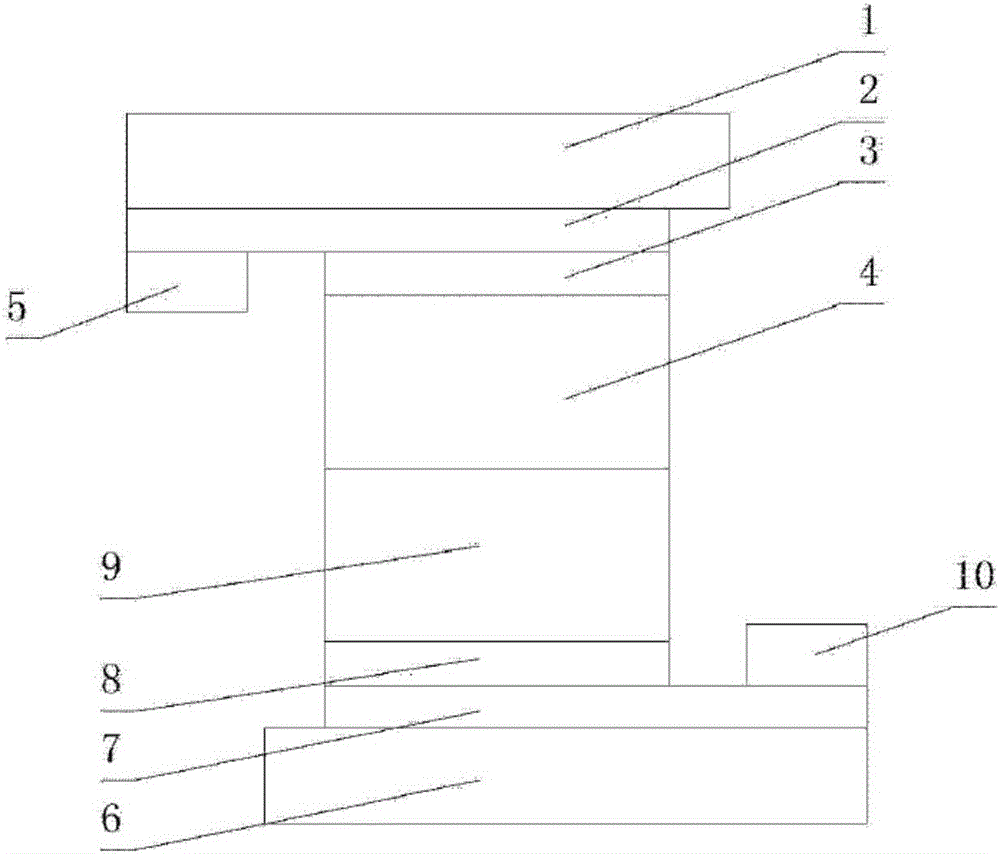

[0067] Figure 5 is a schematic diagram of the LED packaging structure of this embodiment, Image 6 It is a schematic structural diagram of the separation of the upper and lower transparent substrates, and its structure is similar to that of Embodiment 1, except that:

[0068] The number of LED chips 101 is 5, wherein the N electrodes 102 of two chips face the transparent upper substrate 201, and the N electrodes 102 of the other three chips face the transparent lower substrate 301, and the LED chips 101 of different orientations are arranged at intervals; The main material of the substrate 201 is transparent ceramics, a patterned first transparent conductive layer 202 is arranged on one surface, and a first conductive circuit layer 205 is also arranged on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com