Production method of high-capacity and long-cycle lithium-rich 622-type ternary cathode material

A technology of positive electrode material and production method, which is applied in the production field of high-capacity and long-cycle lithium-rich 622 type ternary positive electrode material, can solve the problems of high-temperature cycle performance and high-temperature storage performance of nickel-cobalt lithium manganese oxide, and achieve improved electrochemical performance. Gram capacity, improved cycle performance, and complete crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

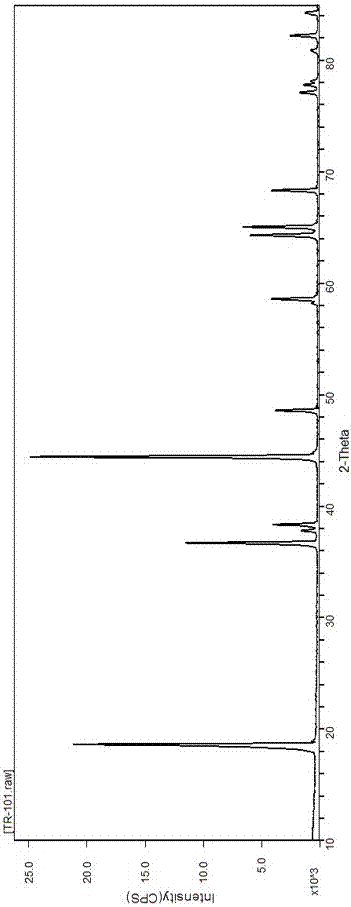

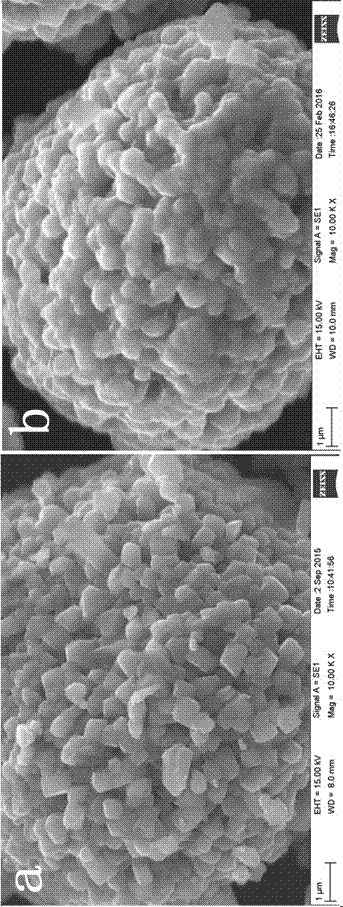

Image

Examples

Embodiment 1

[0031] The production method of high-capacity and long-cycle lithium-rich 622 type ternary positive electrode material comprises the following steps:

[0032] a. Raw material pretreatment: sieve the battery-grade lithium carbonate raw material to 150 mesh, and put the lithium carbonate under the sieve into production;

[0033] b. Ingredients: Weigh 75kg ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 , the weight of lithium carbonate is calculated and weighed according to the ratio of molar ratio Li: (Ni+Co+Mn)=1.08, and the titanium content mixed with nano-scale titanium dioxide is 75kg×1.065 (theoretical quality of the product corresponding to the ternary precursor of 75kg) 0.5% calculation, and then converted into the weight of titanium dioxide;

[0034] c. Mixing of raw materials: Put the weighed lithium carbonate, ternary precursor and titanium dioxide into the high-speed mixer in turn to mix, mix at low speed for 10 minutes, and mix at high speed for 90 minutes. Afte...

Embodiment 2

[0042] The production method of high-capacity and long-cycle lithium-rich 622 type ternary positive electrode material comprises the following steps:

[0043] a. Raw material pretreatment: sieve the battery-grade lithium carbonate raw material to 150 mesh, and put the lithium carbonate under the sieve into production;

[0044] b. Ingredients: Weighing 75kg ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 , the weight of lithium carbonate is calculated and weighed according to the ratio of molar ratio Li: (Ni+Co+Mn)=1.15, and the titanium content mixed with nano-titanium dioxide is 75kg×1.065 (theoretical quality of the product corresponding to 75kg ternary precursor) 2.3% calculation, and then converted into the weight of titanium dioxide;

[0045] c. Mixing of raw materials: Put the weighed lithium carbonate, ternary precursor and titanium dioxide into the high-speed mixer in turn to mix, mix at low speed for 10 minutes, and mix at high speed for 90 minutes. After mixing, ...

Embodiment 3

[0050] The production method of high-capacity and long-cycle lithium-rich 622 type ternary positive electrode material comprises the following steps:

[0051] a. Raw material pretreatment: sieve the battery-grade lithium carbonate raw material to 150 mesh, and put the lithium carbonate under the sieve into production;

[0052] b. Ingredients: Weighing 75kg ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 The weight of lithium carbonate is calculated and weighed according to the molar ratio Li: (Ni+Co+Mn) = 1.15, and the aluminum content mixed with nano-aluminum hydroxide is 0.9 (theoretical quality of the product corresponding to the ternary precursor body of 75kg) % calculation, and then converted to the weight of aluminum hydroxide;

[0053] c. Raw meal mixing: Pour the weighed lithium carbonate, ternary precursor and aluminum hydroxide into a high-speed mixer in turn to mix, mix at a low speed for 10 minutes, and mix at a high speed for 90 minutes. After mixing, check th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap