Fireproof ventilation capacitance compensation cabinet

A capacitor compensation cabinet and cabinet technology, applied in the field of capacitor compensation cabinets, can solve problems such as affecting the service life of electrical components, reducing the service life of equipment, damaging voltage quality, etc., to enhance ventilation and heat dissipation, prolong service life, and have high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

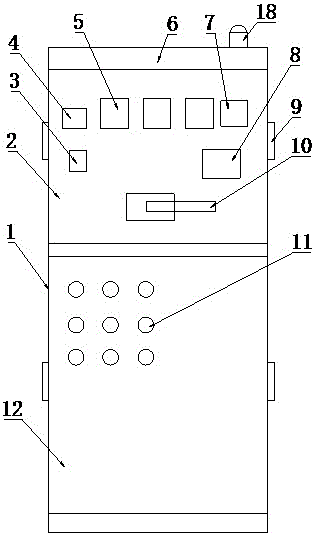

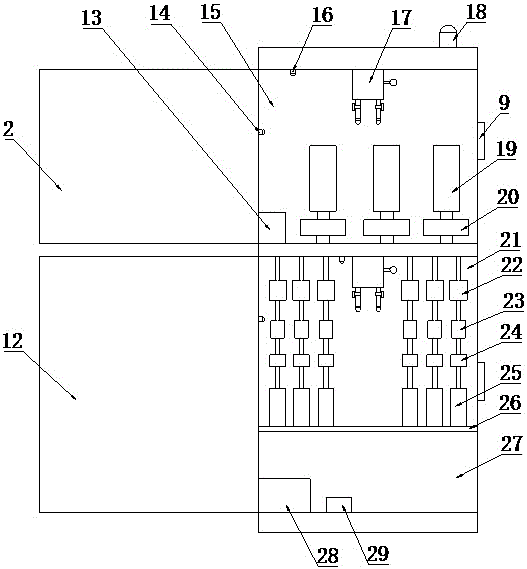

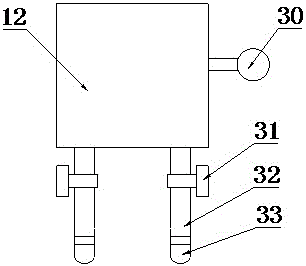

[0022] see Figure 1-4 , a fire-proof and ventilated capacitor compensation cabinet, comprising a cabinet body 1; the cabinet body 1 is divided into an upper cabinet body 15 and a lower cabinet body 21, and the front ends of the upper cabinet body 15 and the lower cabinet body 21 are correspondingly provided with upper cabinet doors 2 and the lower cabinet door 12, the upper cabinet door 2 is provided with a transfer switch 3, a reactive power meter 4, an ammeter 5, a power factor meter 7, a reactive power compensation controller 8 and a knife melting switch interface 10, the lower A plurality of indicator lights 11 are evenly spaced on the cabinet door 12 to indicate the working status of the capacitor compensation cabinet; in order to enhance the ventilation and heat dissipation effect of the cabinet body 1, a fan 9 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com