Sowing machine with multifunctional roller

A seeder and roller technology, applied in the field of coulter components, can solve the problems of uneven accumulation of germinated seeds, inaccurate placement, and yield reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

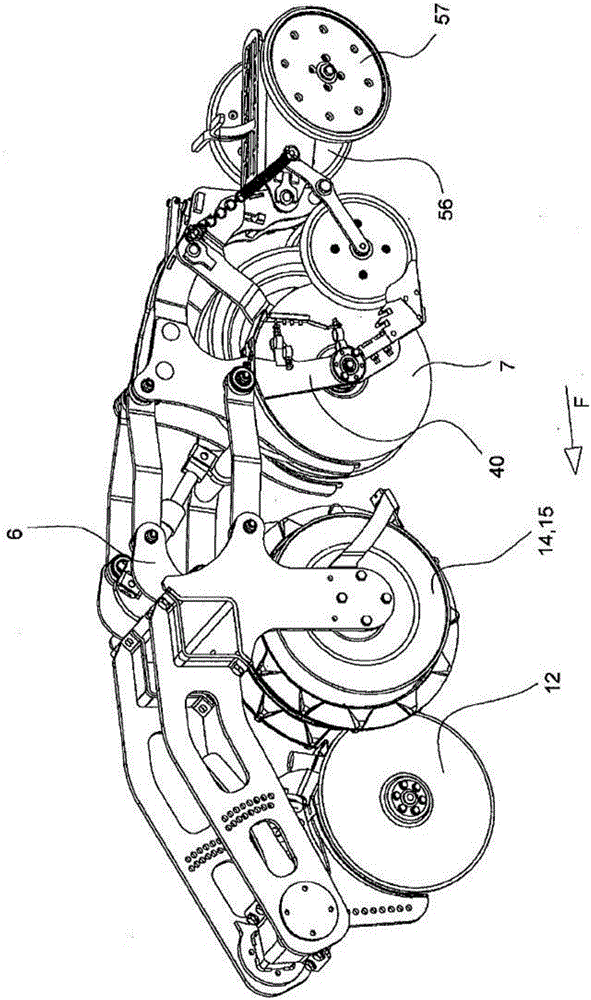

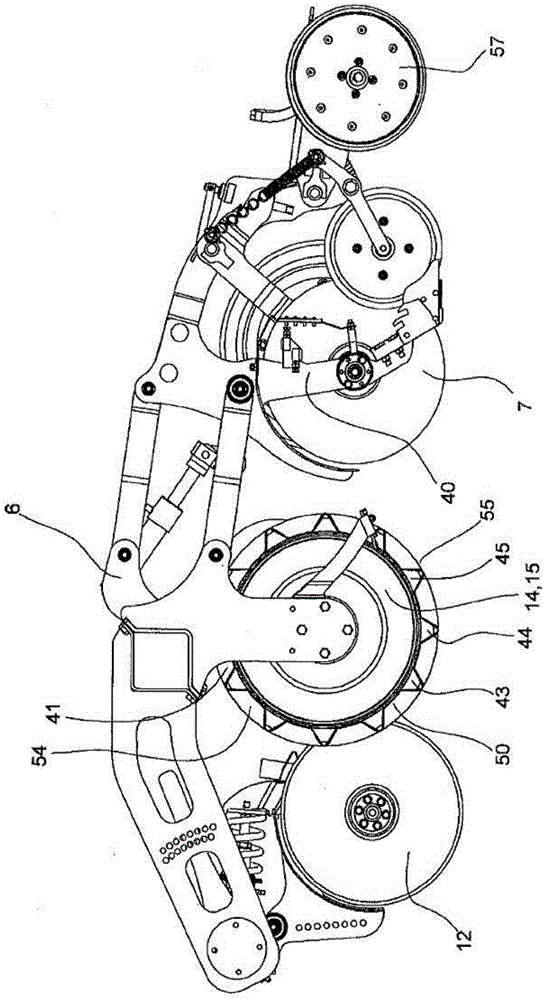

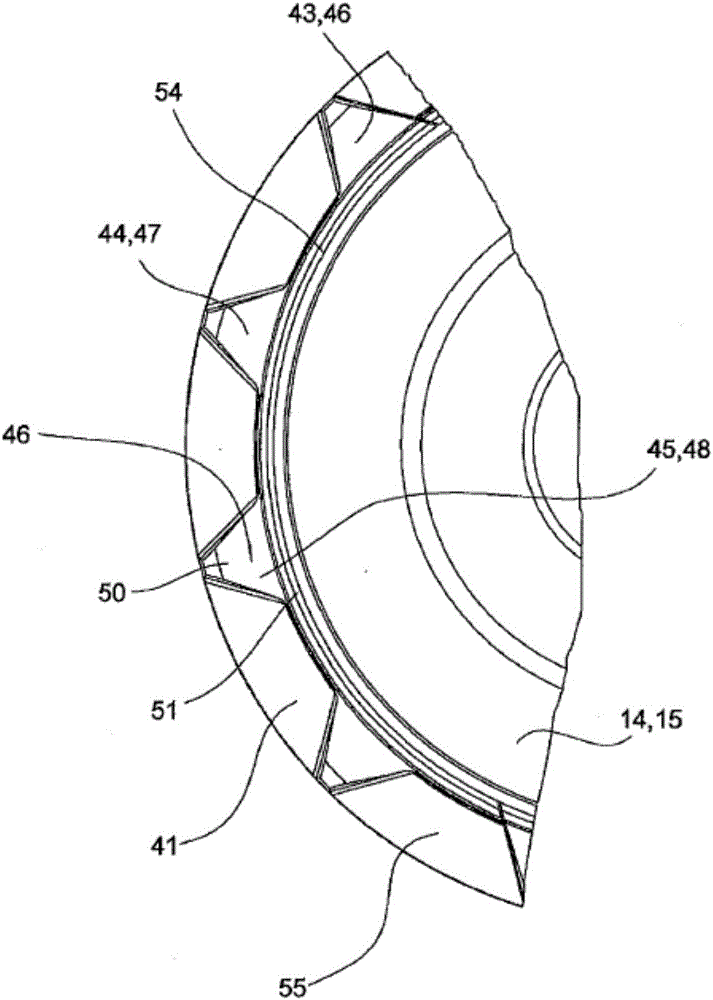

[0030] Such as figure 1 Shown is a precision planter with frame 6, viewed from the direction of travel F, a fertilizer coulter 12 is set, a running device 14 designed as a roller 15, and a sowing coulter 7,8 designed as a double disc coulter, said The sowing coulters 7 , 8 are located on a rotatable, height-adjustable coulter arm 40 and can exert a certain pressure thereon. Behind the unitary structure is another pair of pressure rollers 56,57. A plurality of said frames 6 are connected to and laterally spaced apart from a not shown pipe frame of a precision seed drill. The fertilizer coulter 12 is a double disc coulter with a liquid or solid fertilizer discharge pipe arranged inside. The fertilizer coulter 12 can be designed to be movable relative to the running device 14, supported by spring elastically and / or adjustable in height. In addition, a sweeping device for removing residual vegetation or foreign matter is provided on the upstream side in front of the fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com