Pond circulating aquaculture water treatment system

A technology of recirculating aquaculture and water treatment system, applied in the field of pond recirculation aquaculture water treatment system, can solve the problems of low processing efficiency, large power consumption, unreliability, etc., achieve stable water quality and water level, reduce work intensity and labor costs , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

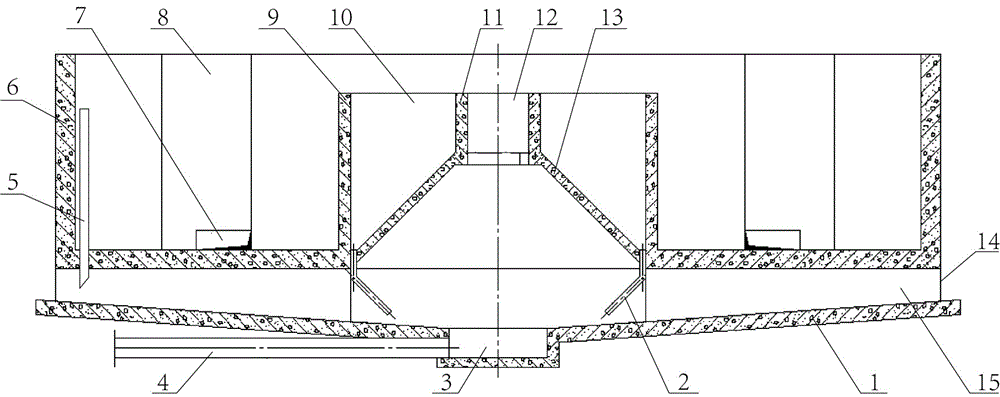

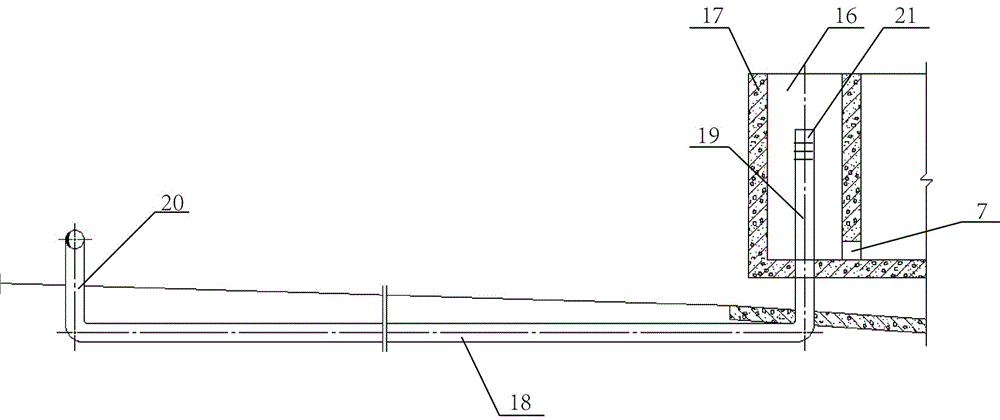

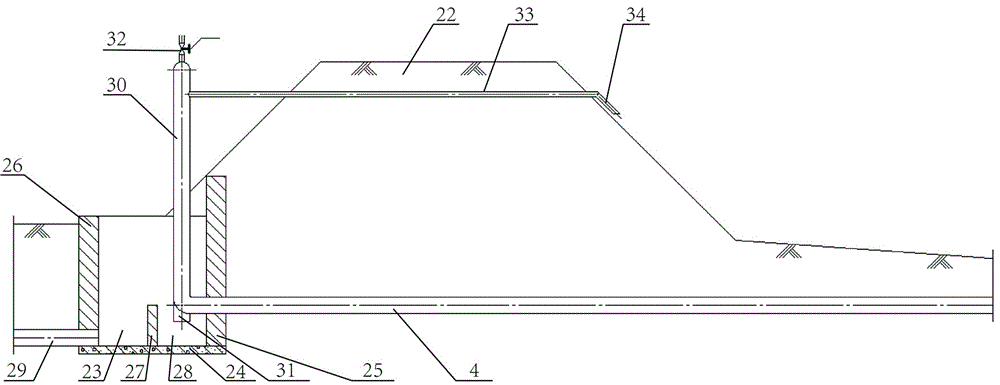

[0020] The embodiment of the present invention includes a centralized treatment pond, a discharge subsystem, an equipment room 35 arranged on the bank of the culture pond, and an operation platform 36 .

[0021] Such as figure 1 As shown, the concentrated treatment pond of the present invention comprises the biological purification pond 8 that is located at the central position of the breeding pond and has the biological purification pond wall 6, and there is a centralized treatment pond bottom space between the bottom of the biological purification pond 8 and the base plate 1 of the cultivation pond 15. Concrete supports are provided in the bottom space 15 of the concentrated treatment tank to support the bottom of the biological purification tank 8 . An escape net 14 is provided between the outer edge of the biological purification pool wall 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com