An automatic screwing device for surgery

A surgical and automatic technology, applied in the field of surgery, can solve the problems of poor operation continuity, reduced operation efficiency, cumbersome operation process, etc., so as to avoid the risk of bone nails being sucked by the suction device and accidentally falling off, improve the operation efficiency, and simplify the operation. The effect of the surgical procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

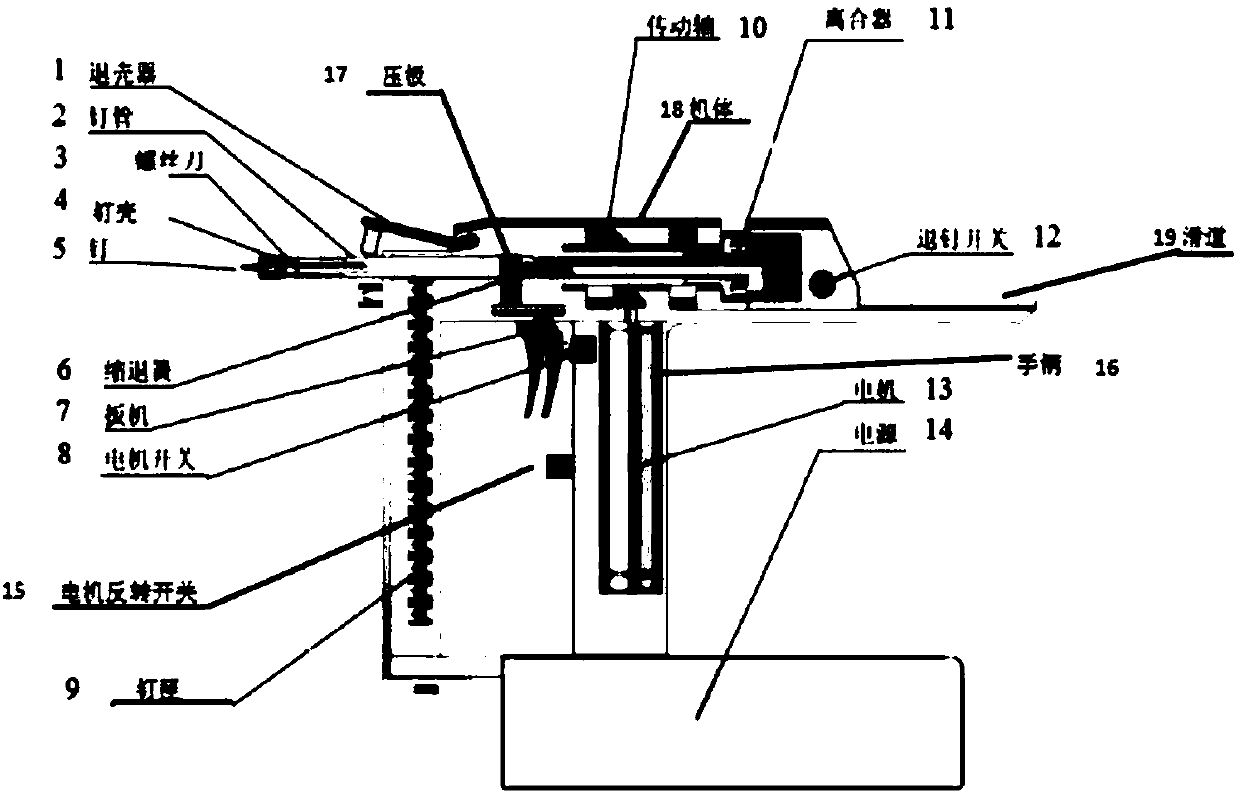

[0035] Embodiment 1: It is a preferred implementation process of the device of the present invention, and the whole process includes: screwing, removing the shell, attaching, and refilling the screws in the nail box.

[0036] The screwing process of the device in the nailing state: as attached image 3 Or as shown in 4, press the trigger (7) and start the motor switch (8), start the motor and reduction unit (13) through the motor switch, after the motor and reducer rotate, they are converted into a Phillips screwdriver (3) through the drive shaft (10) At this time, the screwdriver and the nail tube (2) are relatively displaced under the action of the trigger pressure plate to compress and retract the spring (6), and the bit end of the screwdriver fits the screw (5) and generates a rotational pressure on the screw, which is driven by the rotation of the screwdriver The screw rotates and drills into the bone tissue. After the screw is drilled into the bone tissue, it is separated fr...

Embodiment approach 2

[0041] Another implementation process of the device of the present invention, namely the direct screwing operation of the device, is as attached image 3 As shown, after the screw is attached by the bit end of the screwdriver, press the trigger (7) and then start the motor switch (8), start the motor and reducer unit (13) through the motor switch, after the motor and reducer rotate, pass the drive shaft (10) ) Is converted to the rotation of the screwdriver (3). At this time, the screwdriver and the nail tube (2) have a relative displacement under the action of the trigger pressure plate to compress and retract the spring (6), and the bit end of the screwdriver fits the screw (5) and produces an impact on the screw. Under the action of rotating pressure, the screwdriver rotates to drive the screw to rotate and drill into the bone tissue.

Embodiment approach 3

[0043] Another implementation process of the device of the present invention, namely the reverse screwing operation of the device, when the screw is drilled into the bone, or when the expected effect is not achieved, the screw can be withdrawn from the bone tissue by the device of the present invention, and the screwdriver (3 Press the bit end of the) on the screw to be operated, and then press the motor reverse switch (15) to start the motor and reduction unit (13), the drive shaft (10) rotates in the reverse direction, driving the screwdriver (3) to reverse rotation, and then Pull the screw out of the bone tissue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com