Method for preparing efficient hydrophobic oil-absorbing sponge

An oil-absorbing sponge and hydrophobic technology, applied in the field of functional polymer material preparation, can solve the problems of time-consuming, labor-intensive, and little effect, and achieve the effects of easy availability of raw materials, cheap raw materials, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

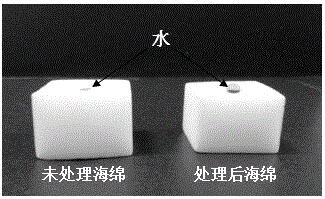

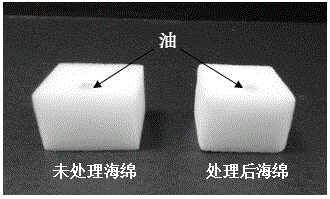

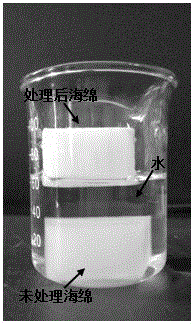

Image

Examples

Embodiment 1

[0016] Add 500 μL of silane coupling agent KH-550 dropwise to 50 mL of PDMS emulsion (solid content 30%), and stir well to obtain a silicone emulsion immersion solution; soak the three-dimensional sponge in the immersion solution, ultrasonically disperse it for 5 minutes, and soak evenly Finally, take out the three-dimensional three-dimensional sponge and squeeze out the excess immersion liquid, and then put it in a vacuum drying oven at 90°C for 8 hours to cure, and then a highly efficient hydrophobic and oil-absorbing sponge is obtained.

Embodiment 2

[0018] Add 250 μL of silane coupling agent KH-550 dropwise to 50 mL of PDMS emulsion (solid content 30%), and stir well to obtain a silicone emulsion immersion solution; soak the three-dimensional sponge in the immersion solution, ultrasonically disperse it for 5 minutes, and soak evenly Finally, take out the three-dimensional three-dimensional sponge and squeeze out the excess immersion liquid, and then put it in a vacuum drying oven at 90°C for 8 hours to cure, and then a highly efficient hydrophobic and oil-absorbing sponge is obtained.

Embodiment 3

[0020] Add 500 μL of silane coupling agent methyl tributylketoxime silane dropwise into 50 mL of PDMS emulsion (solid content 30%), stir well to obtain silicone emulsion immersion solution; soak the three-dimensional sponge in the immersion solution, and ultrasonically Disperse for 5 minutes, soak evenly, take out the three-dimensional three-dimensional sponge and squeeze out the excess immersion liquid, and then put it in a vacuum drying oven at 90 ° C for 8 hours to obtain a high-efficiency hydrophobic and oil-absorbing sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com