Secondary quasi-zero dynamic stiffness suspension and bogie for low-floor trams

A tram and suspension device technology, applied in the field of secondary springs, can solve the problems of poor low-frequency vibration isolation, poor running comfort, and reduced load-carrying capacity, and achieve the advantages of small space occupation, low cost, and good vibration isolation characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

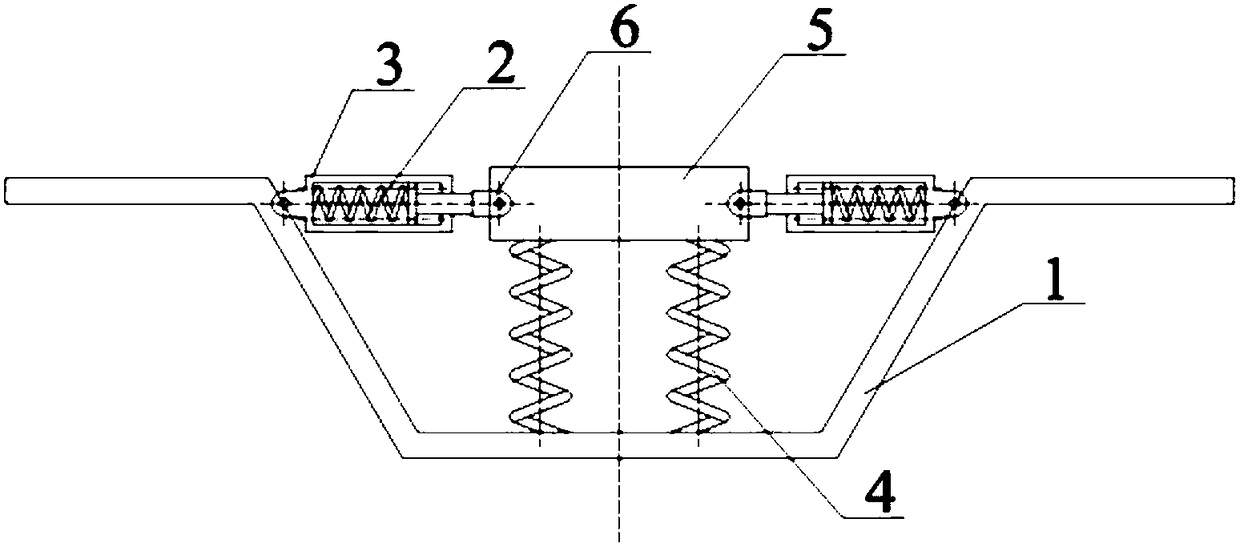

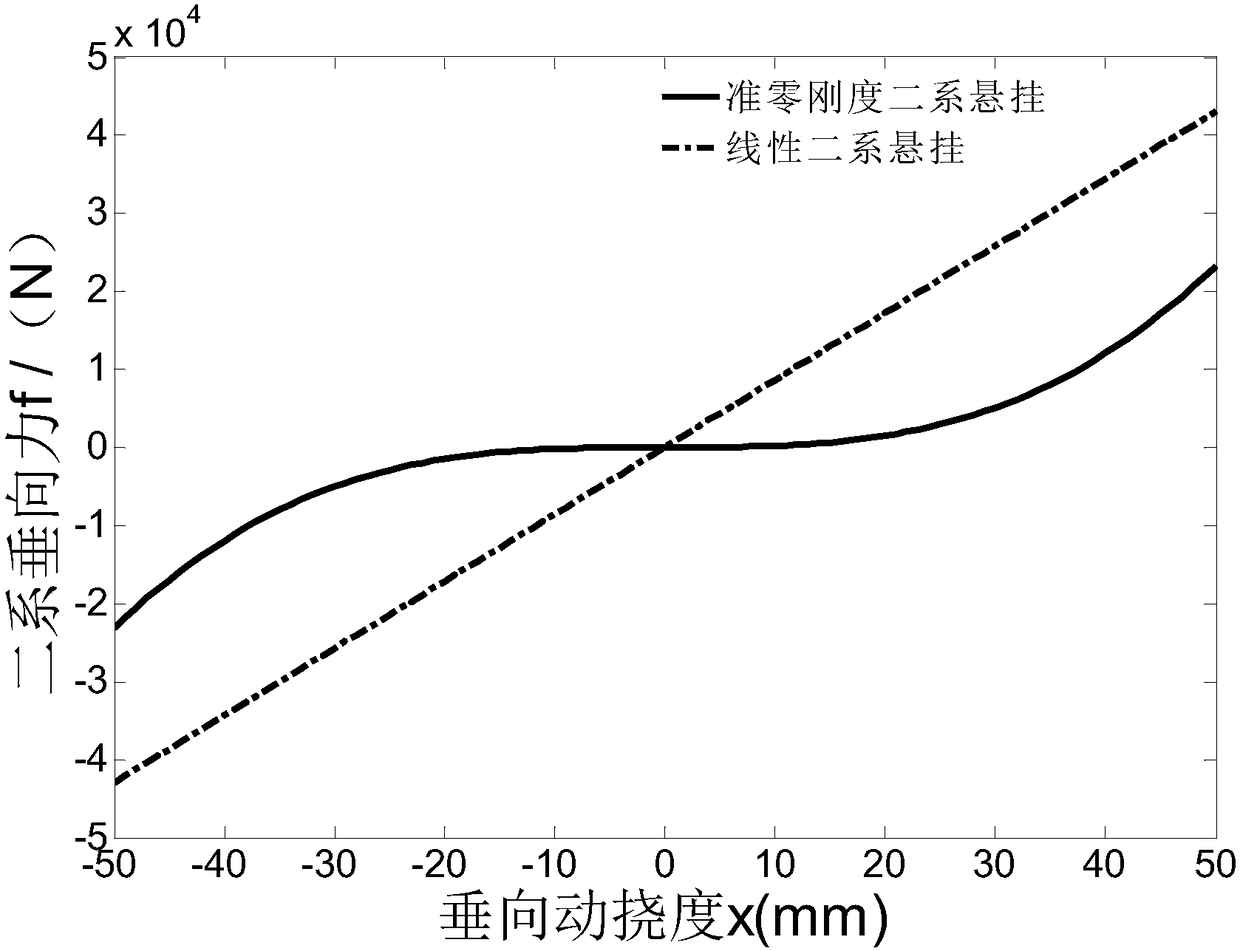

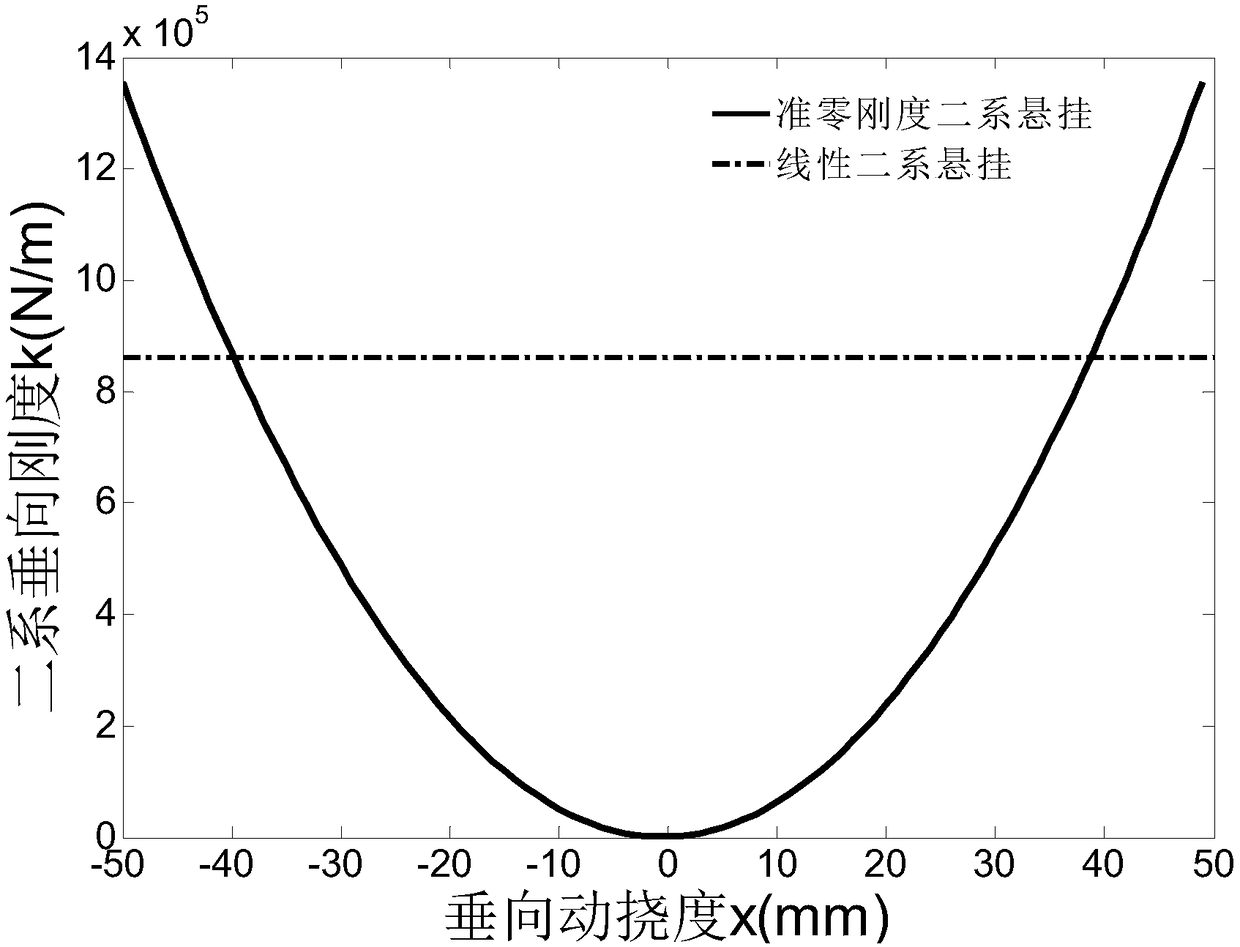

[0028] Such as figure 1 As shown, a secondary quasi-zero dynamic stiffness suspension device for low-floor trams is installed between the car body and the bogie body, including a transverse spring 2, two vertical springs 4 and a The car body connecting piece 5, one end of the transverse spring 2 and one end of the vertical spring 4 are respectively connected with the bar-shaped car body connecting piece 5, the other end of the transverse spring 2 and the other end of the vertical spring 4 are connected with the bogie body respectively, and the transverse spring 2. There are at least two, and they are all in a pre-compressed state. After the two transverse springs 2 are combined, the forces generated in the transverse direction cancel each other out, and the differential of the vertical force to the displacement, that is, the vertical stiffness is a negative stiffness; after being connected in parallel with the vertical spring 4, the entire secondary suspension device has high ...

Embodiment 2

[0037] The difference from Example 1 is that the number of transverse springs 2 and vertical springs 4 can be increased, for example, two pairs of transverse springs 2 and three pairs of vertical springs 4 can be set to reduce the stress on a single spring and prolong the service life .

Embodiment 3

[0039] The suspension device described in embodiment 1 or 2 is applied to the tram bogie, such as figure 1 As shown, during installation, one end of the transverse spring 2 is rotationally connected to the side wall of the U-shaped side beam 1 of the bogie body through a connecting piece or directly, and the vertical spring 4 is fixedly connected to the bottom of the U-shaped side beam 1 of the bogie body , the car body connector 5 is connected with the car body. During installation, there is no need to modify the bogie body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com