Food package detection method

A technology of food detection and detection method, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of false detection of interpersonal relationship, parameter error, and single function, so as to improve work efficiency and strength, reduce detection time, and improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Scope of application of the present invention: it is applicable to the detection of food outer packaging.

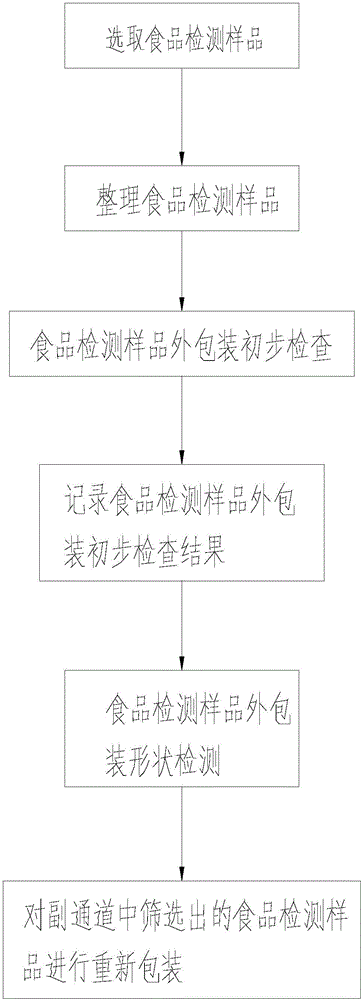

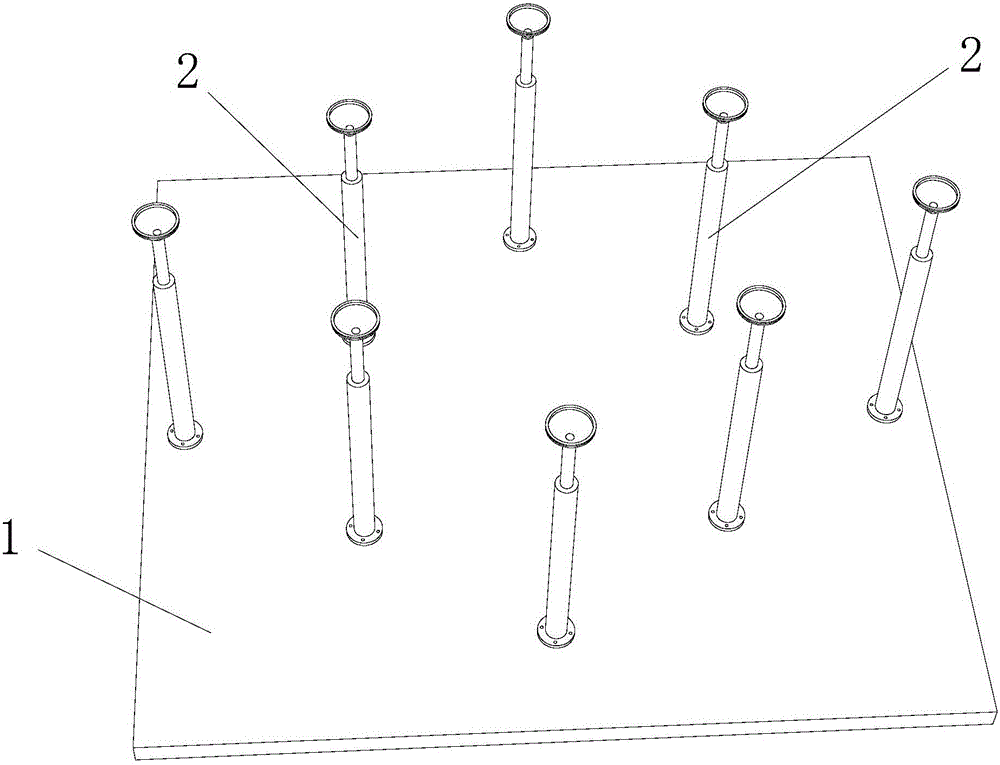

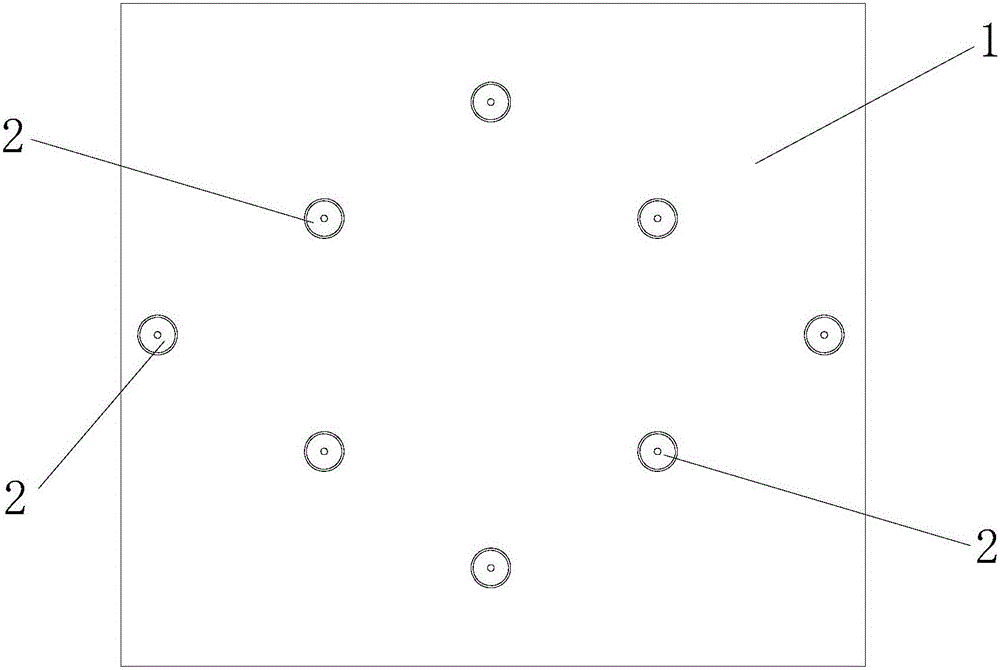

[0027] Such as Figure 1 to Figure 4 Shown, a kind of food packaging detection method comprises the following steps:

[0028] (a) Select food testing samples: use the grasping manipulator to grab the packaged food every 10s, and place the food on the conveying device. The food is distributed in an array on the conveying device for continuous conveying. When one side of the conveying device When the food is collected, open the lifter 1, and the ejection head 2 on the lifter 1 randomly pushes the food out of the conveying device for 30-40cm, and the ejected food is used as a food test sample, and then another manipulator is used to grab the food test sample And placed on the conveyor belt for testing, the food is randomly discharged and tested, automatically sampled, independent of each other, and external human factors are excluded. The food samples tested are rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com