Cotton thread tensioner

A technology of tensioner and cotton thread, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of shortage and other problems, achieve simple structure, convenient operation, and realize the function of adjusting the moving speed of the piston rod Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

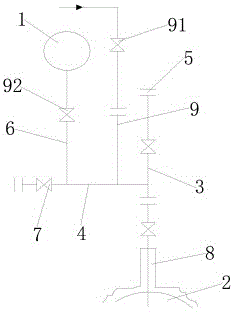

[0010] The present invention will be further described below in conjunction with the accompanying drawings:

[0011] A cotton thread tensioner, including a body, on which an air bag 1 is arranged, the medium in the air bag 1 is hydraulic oil, and the body includes a vertical tube 3 located at the upper end of the thread pushing seat 2 and a vertical tube connected to the vertical tube Intersecting and communicating horizontal pipes 4, the ends of the vertical pipe 3 and the horizontal pipe 4 are provided with gate valves 5, and the branch pipes 6 and the spare pipelines 9 equipped with airbags 1 and throttle valves 92 are helpful to realize The position adjustment function of the piston rod 8 helps to realize the function of adjusting the moving speed of the piston rod 8 again.

[0012] The airbag 1 is arranged on the horizontal pipe 4 through the branch pipe 6, and the horizontal pipe 4 and the vertical pipe 3 are provided with a one-way valve 7, and the one-way valve 7 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com