Cold-resistant plasticizer for cables

A cold-resistant plasticizer and cable technology, applied in the field of power cables, can solve the problems of easy precipitation, influence of flame retardant performance, poor compatibility between plasticizer and resin, etc., and achieve good compatibility and excellent low temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

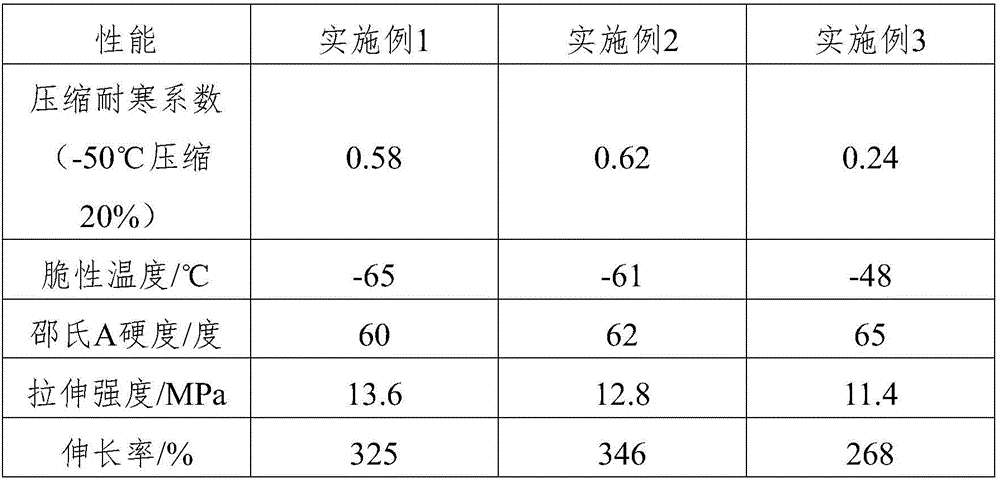

Embodiment 1

[0011] Embodiment 1 Preparation of cold-resistant sheathing material for cables of the present invention

[0012] Weigh 60 kg of PVC, 30 kg of chlorosulfonated polyethylene, 10 kg of 4-methoxy-1,3-phthalic acid bis(4-chlorophenyl) ester, 8 kg of dilauryl thiodipropionate, phosphoric acid 10 kg of tricresyl ester, 15 kg of N,N'-m-phenylene bismaleimide, 20 kg of carbon black, 8 kg of γ-chloropropyl-trimethoxysilane;

[0013] Place PVC and chlorosulfonated polyethylene in a drying oven to dry for 2 hours, seal and cool to room temperature, take out, add to a high-speed internal mixer preheated to 110°C, and stir and mix at a speed of 600 rpm for 5 minutes , add carbon black and tricresyl phosphate, stir at 1000 rpm for 15 minutes, then put the material into a cold mixer, and stir at 200 rpm until the material is cooled to room temperature;

[0014] Send the material to a two-roll mill, add dioctyl terephthalate, dilauryl thiodipropionate, N,N'-m-phenylene bismaleimide and γ-chl...

Embodiment 2

[0015] Embodiment 2 Preparation of cold-resistant sheathing material for cables of the present invention

[0016] Prepared according to the same process as in Example 1, the difference is that the parts by weight of each reagent are different, specifically: 80 kg of PVC, 40 kg of chlorosulfonated polyethylene, 4-methoxy-1,3-phthalic acid di (4-chlorophenyl) ester 20 kg, dilauryl thiodipropionate 5 kg, tricresyl phosphate 12 kg, N,N'-m-phenylene bismaleimide 10 kg, carbon black 30 kg 10 kg of γ-chloropropyl-trimethoxysilane.

Embodiment 3

[0017] The preparation of embodiment 3 comparative example cable sheath material

[0018] The comparative cable sheath material was prepared according to the same process as in Example 1, except that dioctyl terephthalate was used as a plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com