Spraying-free high-metal-gloss transparent ABS material and preparation method

An ABS material and high metal technology, which is applied in the field of spray-free high-metal gloss and transparent ABS materials and preparation, can solve the problems of easy peeling and fading of paint on painted parts, and achieves improvement of gloss and consistency, efficiency, and surface hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

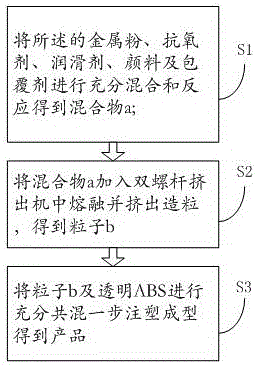

[0055] A method for preparing a spray-free high metallic luster transparent ABS material, the method described in the flow chart of the preparation method comprises the following steps:

[0056] Step S1, fully mixing metal powder, antioxidant, lubricant, pigment and coating agent to obtain mixture a;

[0057] Step S2, adding mixture a to a twin-screw extruder to melt and extrude to granulate to obtain particles b; the melting temperature of adding to the twin-screw extruder is 150°C to 155°C or 155°C to 160°C or 160°C to 165°C or 165°C~170°C or 170°C~175°C or 175°C~180°C, the screw speed of the twin-screw extruder is 300rad / min

[0058] In step S3, the particle b and the transparent ABS are fully blended and injected into a product in one step.

[0059] In step S3, mica powder, antioxidant and lubricant can also be added.

[0060] In step S3, the mixture c is fully blended, and the mixture c is added to a twin-screw extruder to melt and extrude to pelletize; 190°C to 195°C ...

Embodiment 1

[0061] Embodiment 1: A kind of transparent ABS (acrylonitrile-styrene-butadiene copolymer) material with high metallic luster free from spraying, calculated in parts by weight:

[0062] Transparent ABS88 copies

[0063] 0.45 parts of mica powder

[0064] 0.9 parts of metal powder

[0065] Antioxidant 0.18 parts

[0066] Lubricant 0.9 parts

[0067] Pigment 0.004 parts

[0068] 0.45 parts of coating agent.

[0069]Mix 0.9 part of metal powder, 0.09 part of antioxidant, 0.45 part of lubricant, 0.004 part of pigment and 0.45 part of coating agent to obtain mixture a; put mixture a into a twin-screw extruder to melt and extrude to granulate, The melting temperature of the twin-screw extruder is 150°C to 155°C or 155°C to 160°C or 160°C to 165°C or 165°C to 170°C or 170°C to 175°C or 175°C to 180°C. The screw speed of the extruder is 300 rad / min, and the particle b is obtained; the particle b and 88 parts of transparent ABS are fully blended and one-step injection molding is ...

Embodiment 2

[0070] Embodiment 2: A kind of transparent ABS (acrylonitrile-styrene-butadiene copolymer) material with high metallic luster free from spraying, calculated in parts by weight:

[0071] Transparent ABS93 parts

[0072] 0.48 parts of mica powder

[0073] Metal powder 0.95 parts

[0074] Antioxidant 0.19 parts

[0075] Lubricant 0.95 parts

[0076] Pigment 0.0045 parts

[0077] 0.48 parts of coating agent.

[0078] Fully mix 0.95 parts of metal powder, 0.1 parts of antioxidant, 0.5 parts of lubricant, 0.0045 parts of pigment and 0.45 parts of coating agent to obtain mixture a; put mixture a into a twin-screw extruder to melt and extrude to granulate, The melting temperature of the twin-screw extruder is 150°C to 155°C or 155°C to 160°C or 160°C to 165°C or 165°C to 170°C or 170°C to 175°C or 175°C to 180°C. The screw speed of the extruder is 300 rad / min, and the particle b is obtained; the particle b and 93 parts of transparent ABS are fully blended and one-step injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com