Thermochromic polyester fiber and preparation method thereof

A thermochromic and polyester fiber technology, which is applied in fiber treatment, fiber chemical characteristics, single-component polyester rayon, etc., can solve the problems of affecting the performance of textiles, limiting the application range of thermochromic materials, etc. A wide range of effects that add interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

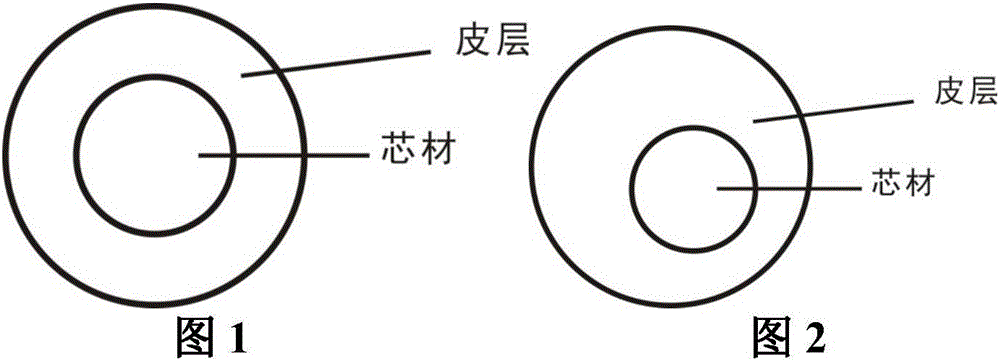

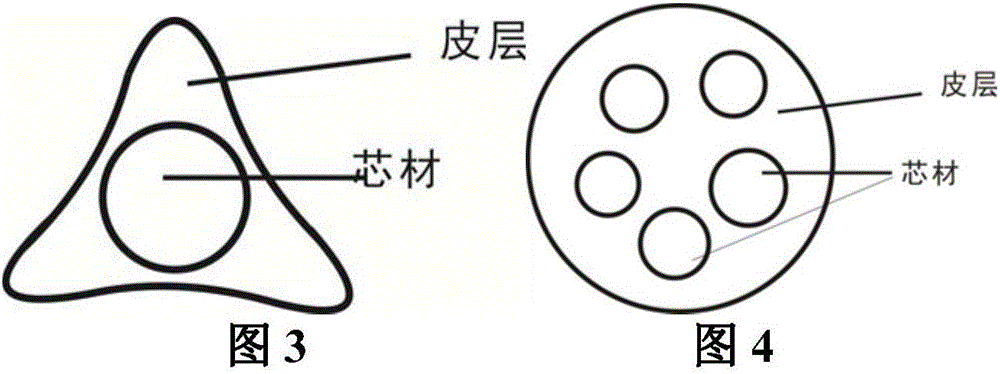

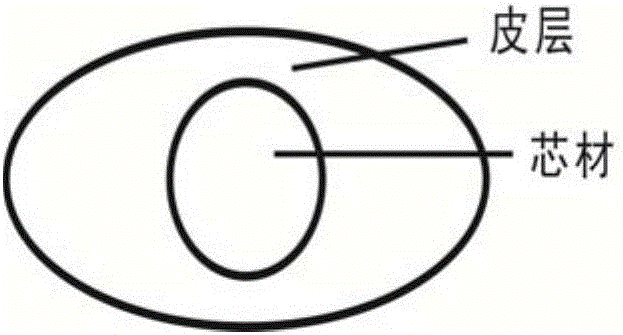

Method used

Image

Examples

Embodiment 1

[0031] Prepare a thermochromic masterbatch capable of changing from red to colorless at about 37°C. Then dry the thermochromic masterbatch at 80°C for 2 hours, and dry the polyester resin chips at 120°C for 4 hours, then weigh 3% of the thermochromic masterbatch, 60% of the core material polyester, and 60% of the skin polyester. Resin 40%. It is mixed evenly, melt-spun, drawn, stretched, and wound into filaments. The spinning speed is 900m / min, and the temperature of each zone of the spinning machine is as follows: zone 1, 250°C; zone 2, 255°C; zone 3, 260°C; zone 4, 265°C; head temperature 265°C, host speed 12r / min , the traction speed is 4000r / min, and finally a polyester fiber that can change from red to colorless at 37°C is obtained.

Embodiment 2

[0033] Prepare a thermochromic masterbatch capable of changing from golden yellow to fluorescent yellow at about 27°C. Then dry the thermochromic masterbatch at 80°C for 2 hours, and dry the polyester resin chips at 120°C for 4 hours, then weigh 3% of the thermochromic masterbatch, 50% of the core material polyester resin, and 50% of the polyester resin in the skin layer. 40% ester resin, 0.5% antistatic agent, mix the thermochromic masterbatch and the core material polyester resin evenly, mix the antistatic agent and the cortex evenly, then melt spinning, pulling, stretching, and winding into filaments . The spinning speed is 880m / min, and the temperature of each zone of the spinning machine is as follows: zone 1, 235°C; zone 2, 255°C; zone 3, 265°C; zone 4, 270°C; head temperature 270°C, host speed 13r / min , the traction speed is 3800r / min, and finally the polyester fiber that can change from golden yellow to fluorescent yellow at about 27°C is obtained.

Embodiment 3

[0035] Prepare thermochromic powder that changes from purple to blue at about 30°C. Dry the thermochromic masterbatch at 90°C for 2.5 hours, dry the polyester resin chips at 100°C for 5 hours, then weigh 5% of the thermochromic masterbatch, 40% of the core material polyester resin, and 40% of the skin layer polyester 45% resin, 0.5% antistatic agent, mix the core material and thermochromic masterbatch evenly, melt spin according to the skin-core structure, draw, stretch, and wind into filaments. The spinning speed is 1000m / min, and the temperature of each zone of the spinning machine is as follows: zone 1, 245°C; zone 2, 255°C; zone 3, 265°C; zone 4, 270°C; head temperature 270°C, host speed 13r / min , the traction speed is 3500r / min, and finally a polyester fiber that can change from purple to blue-yellow at about 30°C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com