Construction method for hanging lifting-lug-free tower type equipment by fishing method

A construction method and fishing method technology, applied in towers, building types, buildings, etc., can solve the problems of low hoisting efficiency, equipment slippage, and cost reduction by the binding method, and achieve the effect of a convenient and fast construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

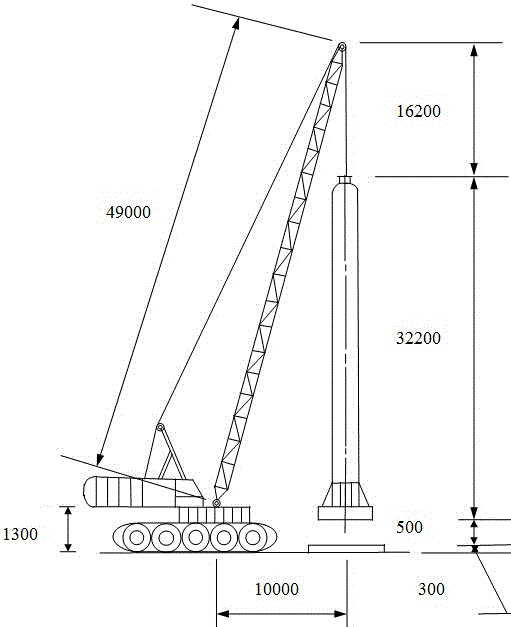

[0010] The shape of the tower equipment in this embodiment is cylindrical, the top is a hemispherical hollow body, and its height is 32200mm.

[0011] According to the position of the suspended tower equipment and the station position of the main crane on site, figure 1 As shown, R=10000mm, h 1 =32200mm, h 2 =16200mm, h 3 =500mm, h 4 =300mm.

[0012] The main crane is a crawler crane.

[0013] Main crane hoisting weight Q 1 =(q 1 +q 2 )k 1 k 2

[0014] where Q 1 ---- hoisting weight of the main crane;

[0015] q 1 ---- Net weight of equipment;

[0016] q 2 ----Hook head and rope weight;

[0017] k 1 ----Dynamic load factor, take 1.1;

[0018] k 2 ----Unbalance coefficient, take 1.1~1.2.

[0019] Main crane jib length

[0020] In the formula: R—the radius of gyration of the main crane (unit is m); R is determined according to the position of the suspended tower equipment and the station position of the main crane on site: it is common knowledge;

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com