Segmented hoisting construction method for large-span spherical crown-shaped net rack structure

A grid structure, segmented hoisting technology, applied in the direction of hoisting device, transportation and packaging, building construction, etc., can solve the problems of low work efficiency and high risk coefficient, improve the use efficiency, reduce safety risks, construction methods Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

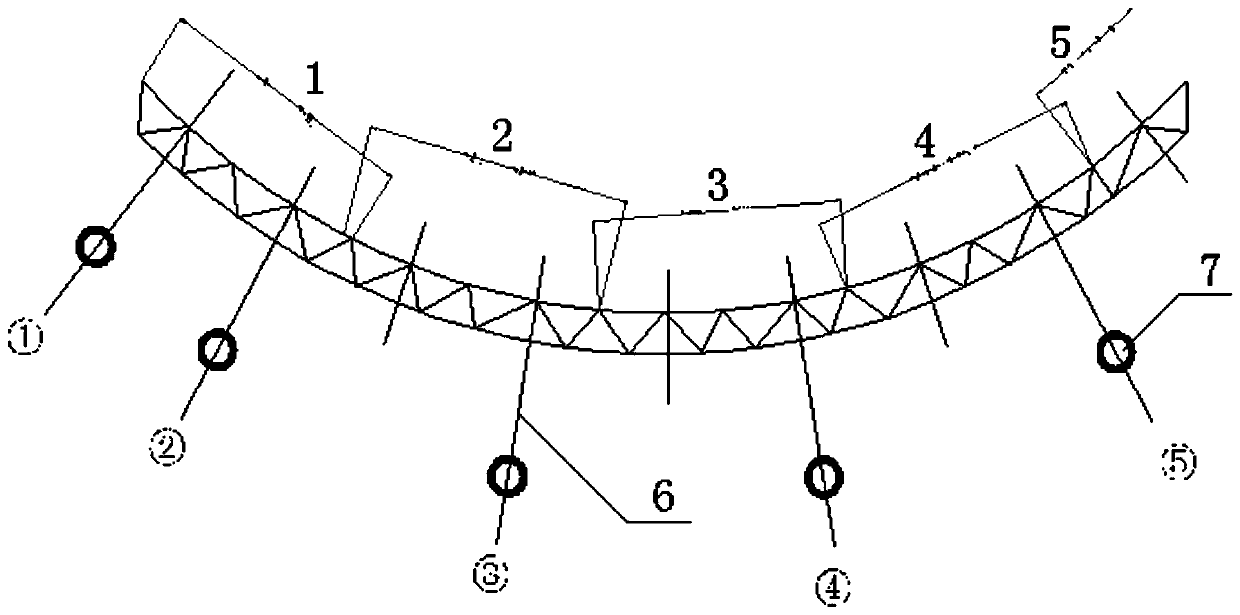

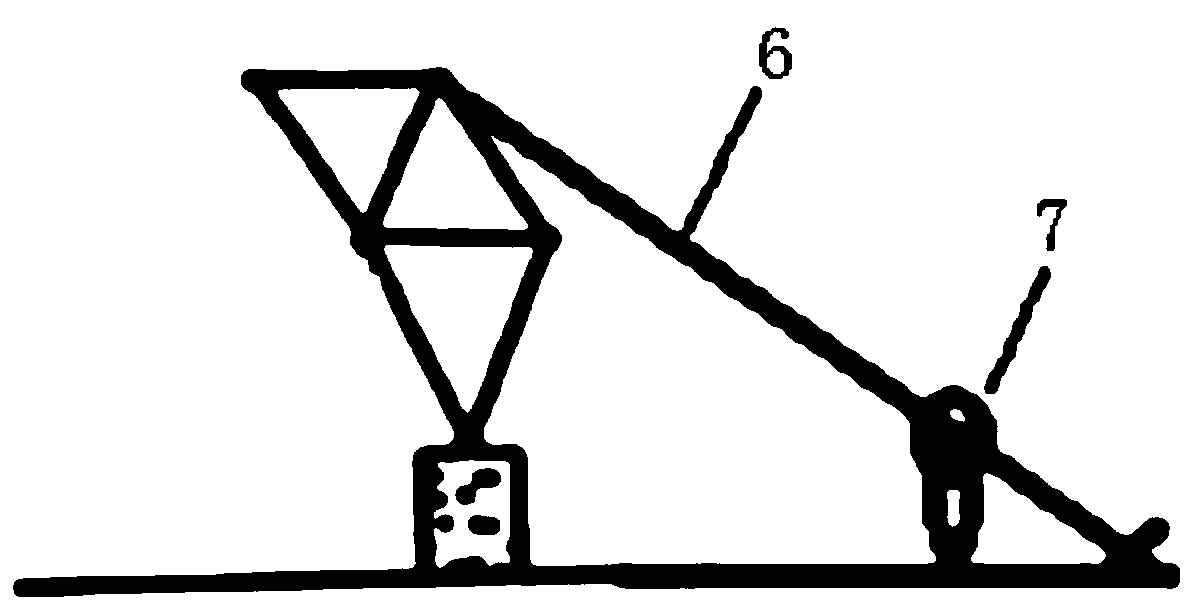

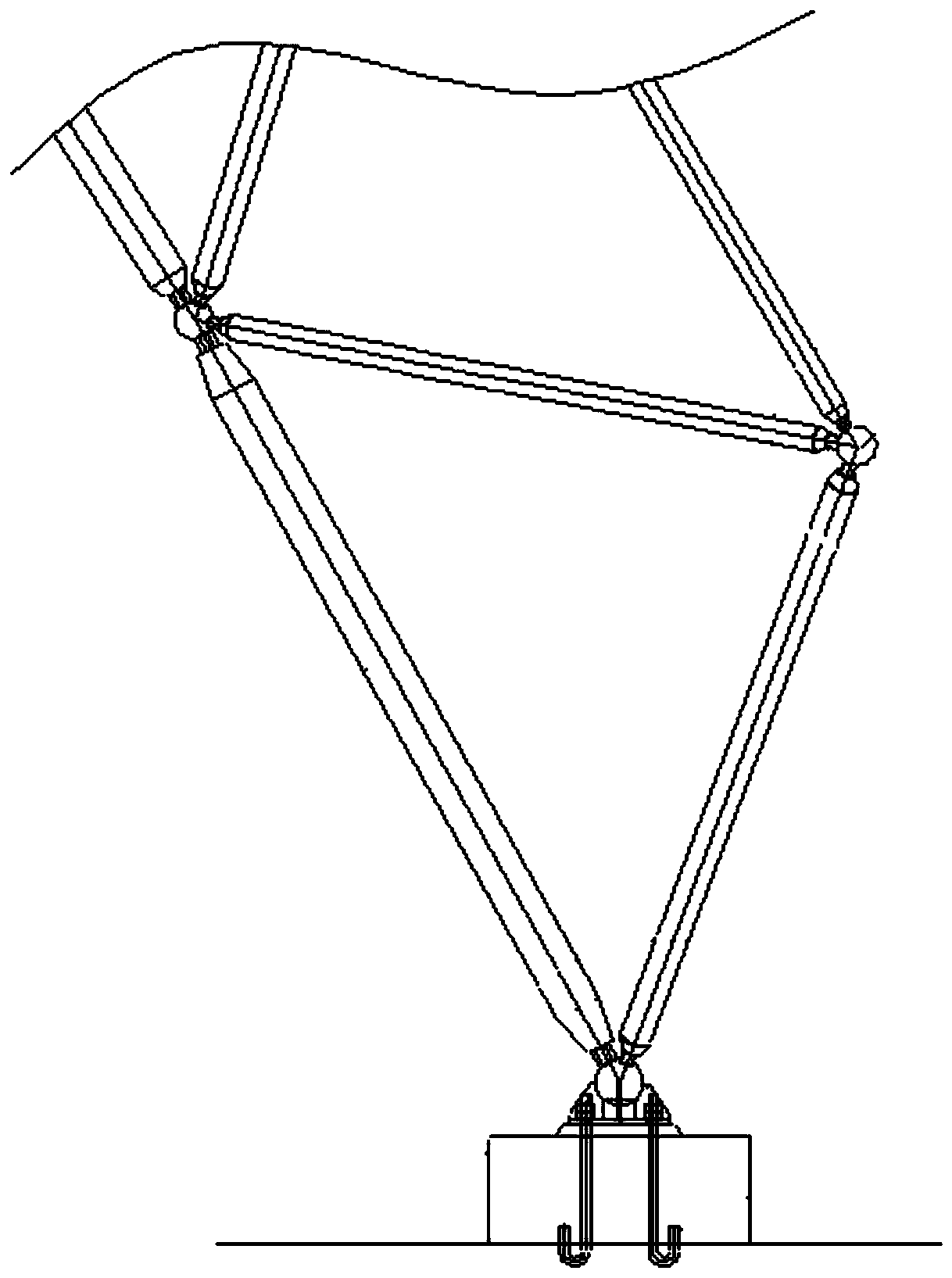

[0028] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0029] The segmental hoisting construction method of the large-span spherical crown-shaped grid structure adopts the layered and segmented hoisting method to install the spherical crown-shaped grid. After the first section of the grid assembly unit of each layer is hoisted,

[0030] First, set two back-pull wind ropes on the first section of grid assembly unit, and the distance between the two wind ropes is one end;

[0031] Secondly, hoist from the next section of grid assembly unit in turn, and after each section of grid assembly unit is hoisted, a back-pull type cable wind rope is installed on the section of grid assembly unit;

[0032] Then, remove the cable wind rope in the middle position until the grid assembly unit of this layer forms an arc, and then remove all the cable wind ropes;

[0033] Finally, continue to hoist the subseque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com