Slot type concentrated solar Sterling power generation system

A trough solar and power generation system technology, applied in the field of solar free piston Stirling power generation system, can solve the problems of large initial investment, long construction period, complex structure, etc., and achieve a short construction period, flexible construction and environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

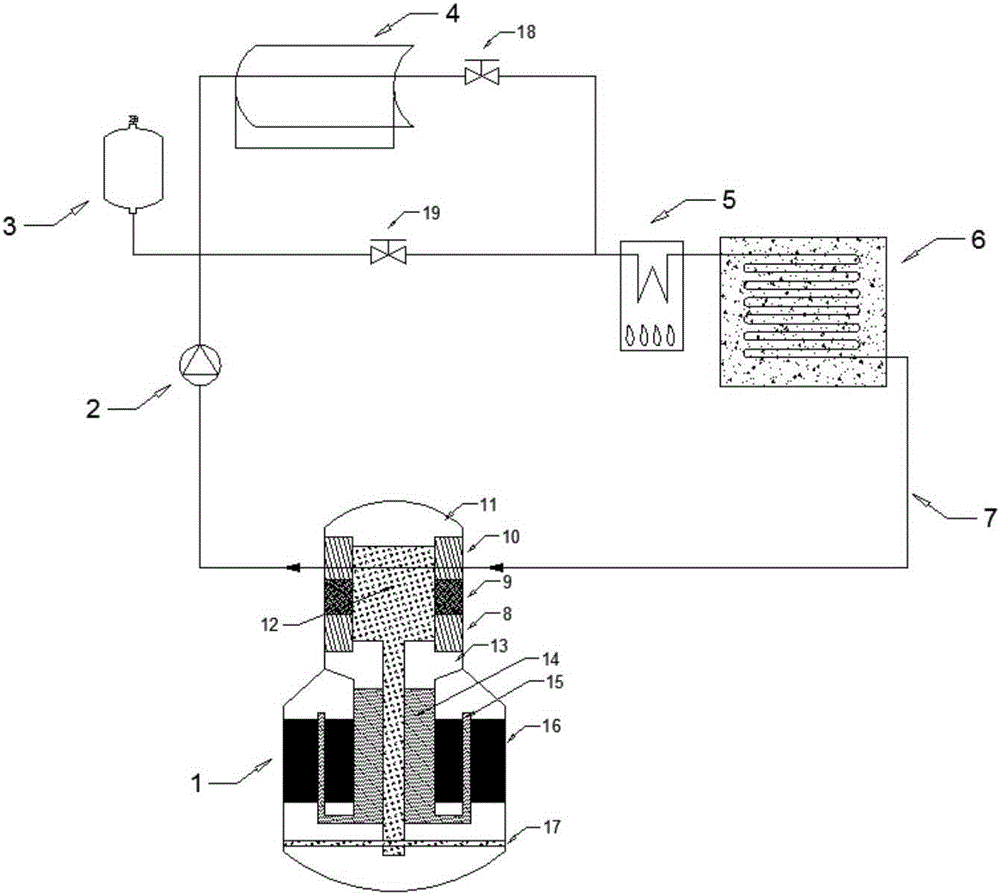

[0030] Such as figure 1 As shown, a trough-type concentrating solar Stirling power generation system provided in this embodiment includes a trough-type solar collector 4, a circulation pump 2 and a free-piston Stirling generator 1, and a thermal fluid delivery pipeline 7 for Connecting all components in the system, the trough solar collector 4, the circulation pump 2 and the free piston Stirling generator 1 are connected in sequence through the thermal fluid delivery pipeline 7 to form a power generation circuit.

[0031] The trough solar collector 4 adopted in this embodiment can effectively reduce the system cost and increase the reliability of the system at the same time. The trough solar collector 4 heats the heat transfer fluid inside it by reflecting sunlight, so that the heat transfer fluid The operating temperature is between 350-400°C; the circulation pump 2 is set on the heat fluid pipeline 7, and the appropriate model can be selected according to the heat transfer f...

Embodiment 2

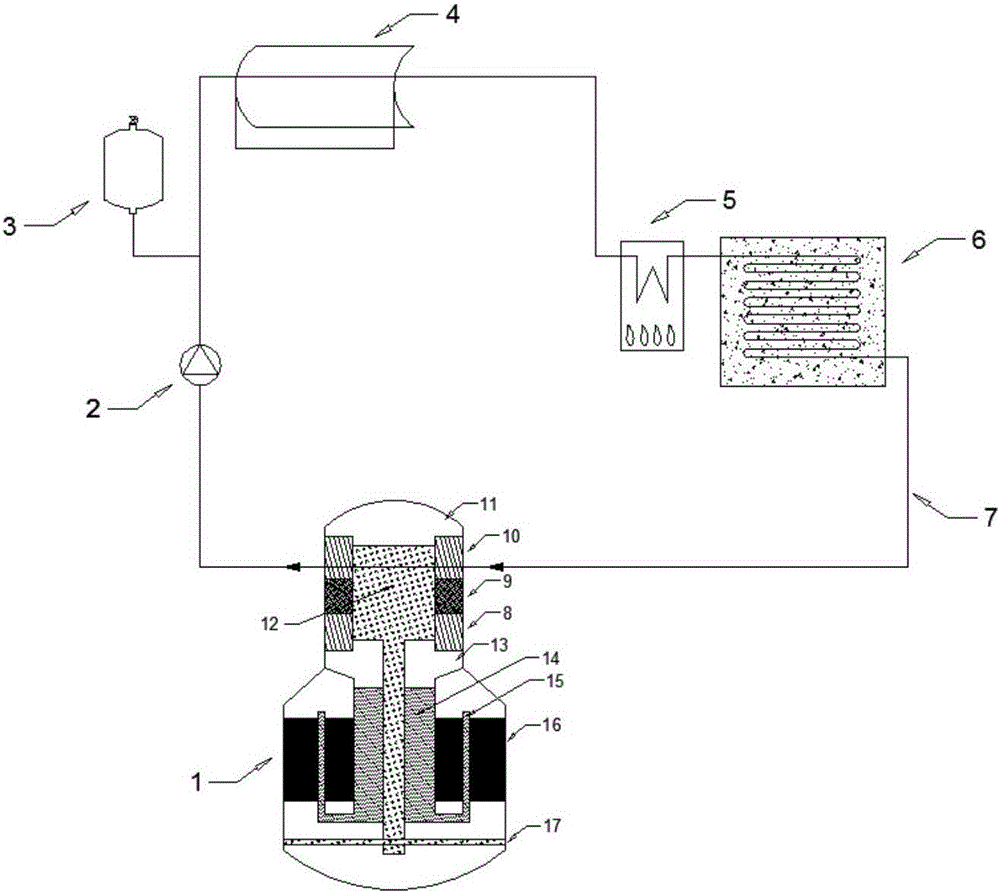

[0043] Such as figure 2 As shown, a trough-type concentrating solar Stirling power generation system provided by this embodiment has the same principle as that of Embodiment 1, and its structure is similar to that of Embodiment 1. The only difference is that in this embodiment, the post-combustion device 5 The inlet is only connected to the fluid outlet of the trough solar collector 4 , that is, the inlet of the afterburning device 5 is not connected to the thermal fluid pipeline 7 for communicating with the fluid outlet of the circulation pump 2 . And in this embodiment, no valve is set in the thermal fluid pipeline 7 between the inlet of the afterburning device 5 and the fluid outlet of the trough solar collector 4 .

[0044] The setting of this structure makes the system of this embodiment when the sunlight is sufficient during the day, the trough solar collector 4 provides thermal energy for the whole system, and the thermal storage device 6 is used to store the excess he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com