Temperature-adjusting type waste heat boiler

A waste heat boiler and temperature adjustment technology, which is applied in lighting and heating equipment, steam generation method using heat carrier, steam generation, etc., can solve the problems that cannot meet the emission reduction requirements, and the waste heat boiler cannot perform temperature adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

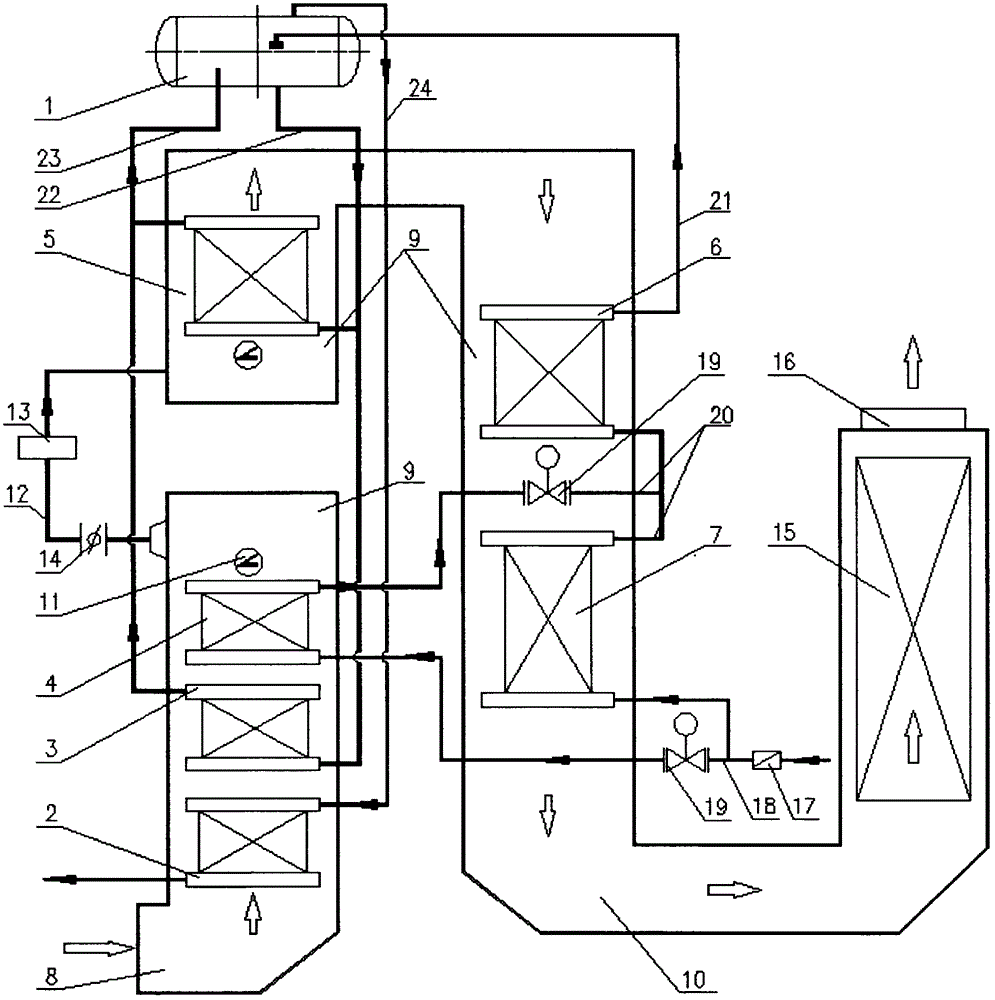

[0011] exist figure 1 A temperature-regulating waste heat boiler is shown, including a drum 1, a superheater 2, a high-temperature evaporator 3, a temperature-regulating water heater 4, a low-temperature evaporator 5, an economizer 6, a water heater 7, an inlet flue 8, and a main body flue gas Road 9 and outlet flue 10, characterized in that the temperature-regulating waste heat boiler is arranged in an inverted U shape, the inlet flue 8 and the body flue 9, the body flue 9 and the outlet flue 10, and the outlet flue 10 and the The pollutant co-removal device 15, the pollutant co-removal device 15 and the tail flue 16 are connected in sequence, and the superheater 2, the high-temperature evaporator 3, the temperature-adjusting water heater 4, the low-temperature evaporator 5, and the coal-saving 6, water heater 7; temperature measuring instrument 11 is installed on the body flue 9 between the temperature-adjusting water heater 4 and the low-temperature evaporator 5; a transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com