A cross-axis image measurement method for three-dimensional motion analysis of glass pipelines

A three-dimensional motion and image measurement technology, applied in measurement devices, photogrammetry/video measurement, surveying and navigation, etc., can solve problems such as tracking failure, motion damping, and inability to extract marker points, and improve accuracy and precision. , the effect of promoting application and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

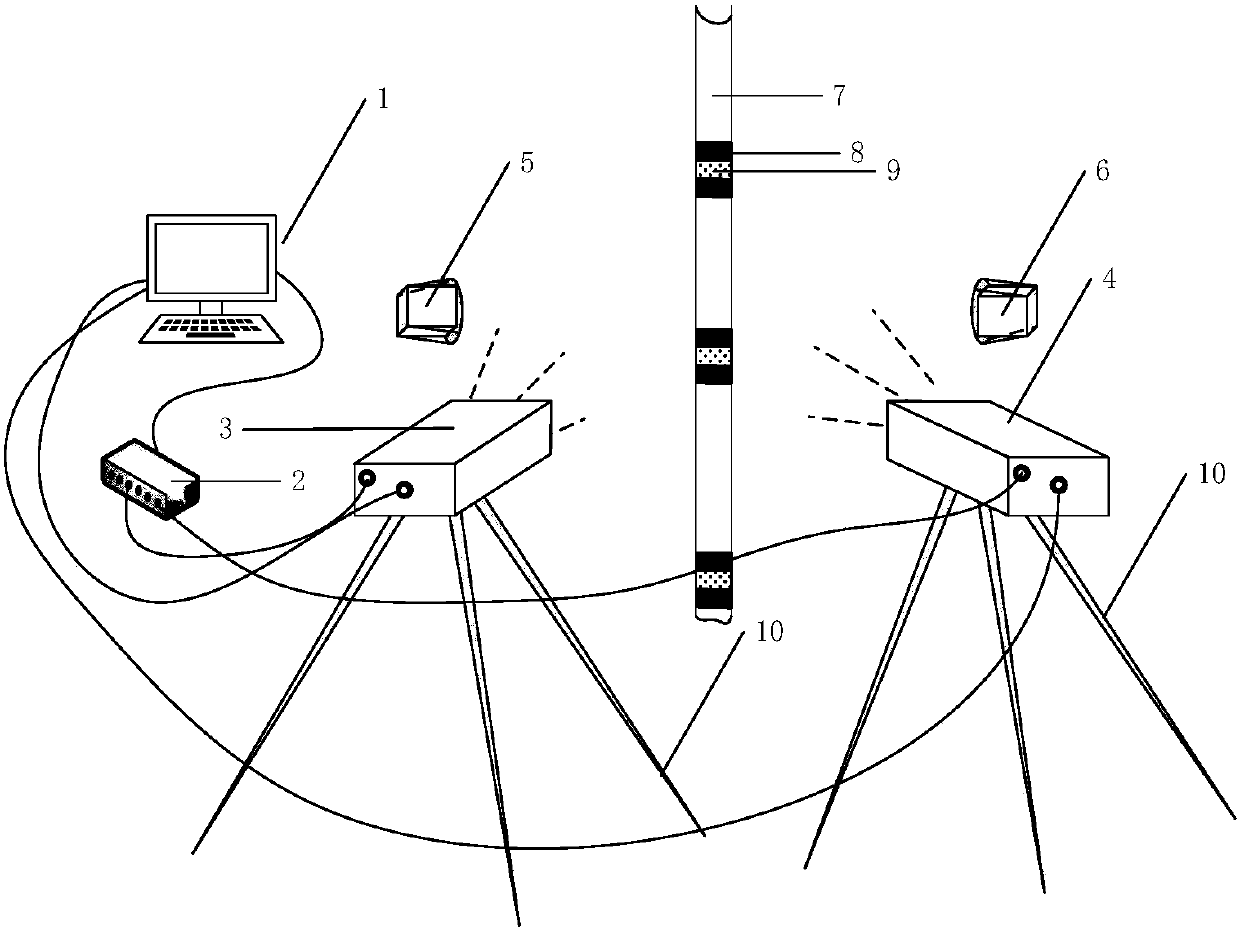

[0023] The device that method of the present invention adopts, its structural representation is as attached figure 1 Shown:

[0024] The cross-axis image measurement system for three-dimensional motion analysis of glass pipelines includes a computer 1, a synchronous controller 2, two high-speed industrial cameras (camera 3 and camera 4), two LED supplementary lights (complementary light 5 and Fill light 6), glass pipeline 7, black spraying stripes 8, yellow fluorescent stripes 9, tripod 10. The camera 3 and the camera 4 are fixed on the tripod 10, arranged on both sides of the pipeline axis (arranged across the axis) and at a certain angle to each other to observe the target pipeline 7, and connected to the computer 1 through a transmission wire. The control port of the synchronous controller 2 is connected with the computer 1, and the synchronous signal output port is connected with two cameras, and is responsible for the synchronous acquisition control of images. And two L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com