An optical cable automatic stripping sampling device and an optical cable sampling method

A technology of automatic stripping and sampling device, applied in the field of optical cable manufacturing, can solve the problems of affecting test accuracy, large damage to sample performance, low test accuracy, etc., and achieves the effect of reducing sampling difficulty, reducing manual labor, and improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

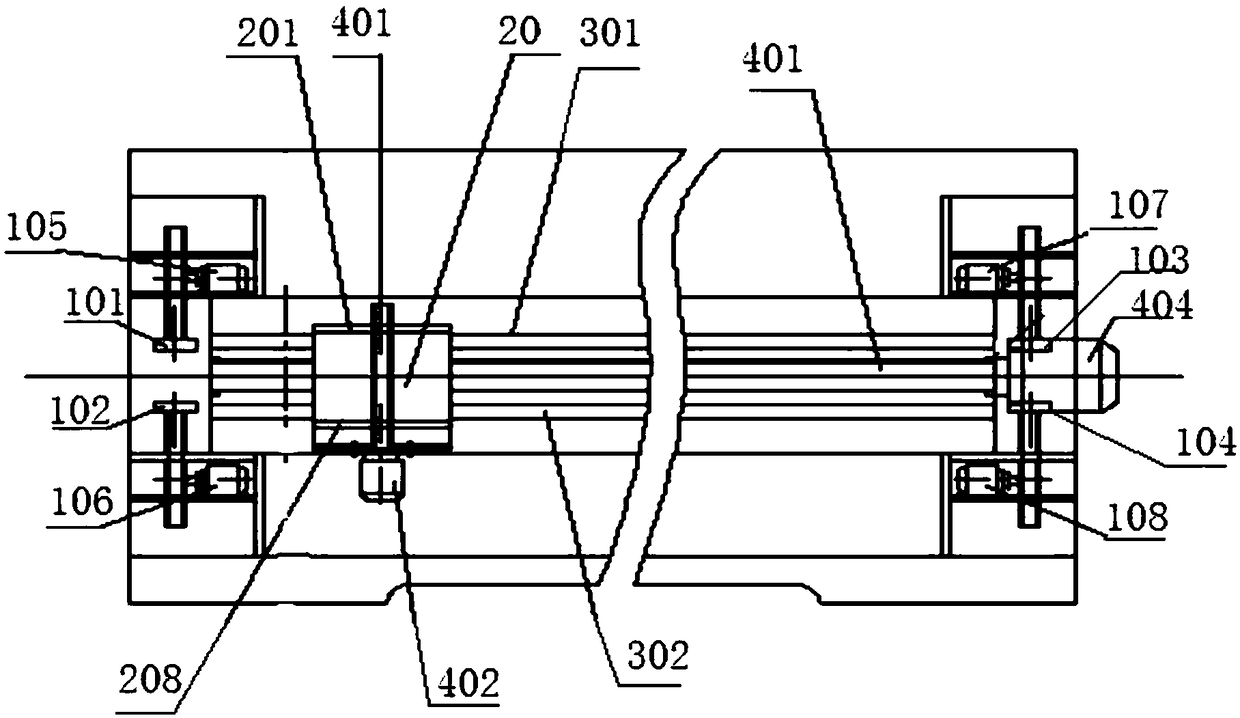

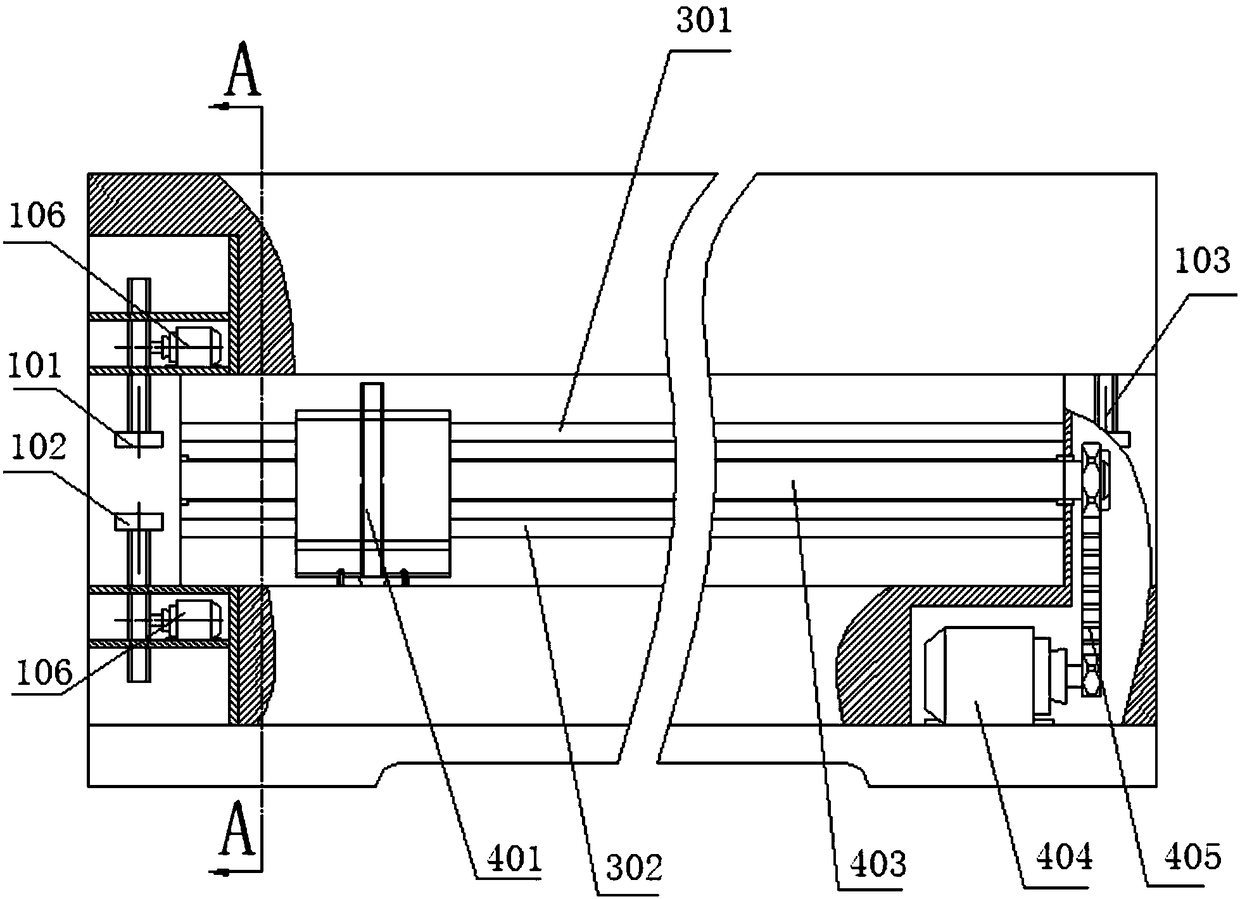

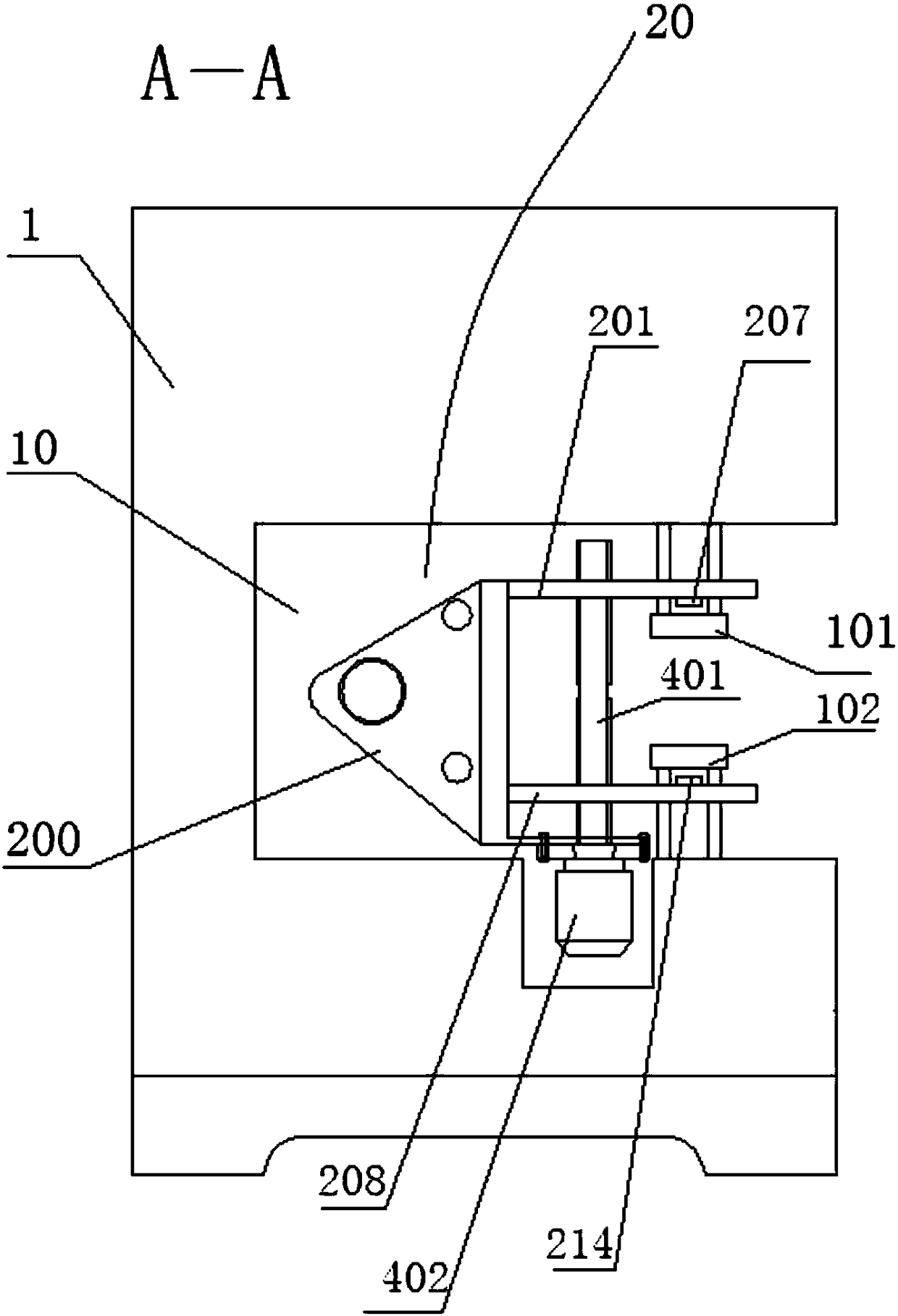

[0035] A kind of optical cable automatic stripping device is disclosed in embodiment 1, and this device is as Figure 1-6 As shown, it mainly includes a frame 1, on which a working space 10 for optical cable stripping and sampling is provided.

[0036]In the process of stripping and cutting the optical cable, the first step is to clamp and straighten the optical cable. The above-mentioned device realizes this function through the clamping parts that cooperate with each other. Specifically, the first clamping part is provided on the above-mentioned frame 1 101. The second clamping piece 102, the third clamping piece 103 and the fourth clamping piece 104, wherein the clamping ends of the first clamping piece 101 and the third clamping piece 103 face downward, and the second clamping piece 103 faces downward. The clamping ends of the clamping piece 102 and the fourth clamping piece 104 face upward, the above-mentioned first clamping piece 101 cooperates with the above-mentioned s...

Embodiment 2

[0050] Embodiment 2 discloses the sampling method of the optical cable automatic stripping sampling device in embodiment 1, which specifically includes the following steps:

[0051] Step 1. Place the optical cable to be sampled in the working space 10 on the frame, and the above-mentioned first clamping motor 105, second clamping motor 106, third clamping motor 107, and fourth clamping motor 108 respectively drive the above-mentioned The first clamping part 101 , the second clamping part 102 , the third clamping part 103 and the fourth clamping part 104 clamp the two ends of the optical cable to straighten the optical cable.

[0052] Step 2, the above-mentioned first motor 402 drives the above-mentioned first lead screw 401 to rotate, and the above-mentioned first lead screw 401 rotates to drive the above-mentioned second tool carrier 208 to move toward the above-mentioned first tool carrier 201, so that the above-mentioned first cutting assembly and the second cutting assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com