Method for determining temperature process curve of mass concrete with ultrahigh volume of fly ash

A large-volume concrete and concrete technology, applied in solid waste management, sustainable waste treatment, instruments, etc., can solve the problem that the amount of fly ash cannot be increased, the influence of temperature performance has not been studied, and low-grade ash cannot be used, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

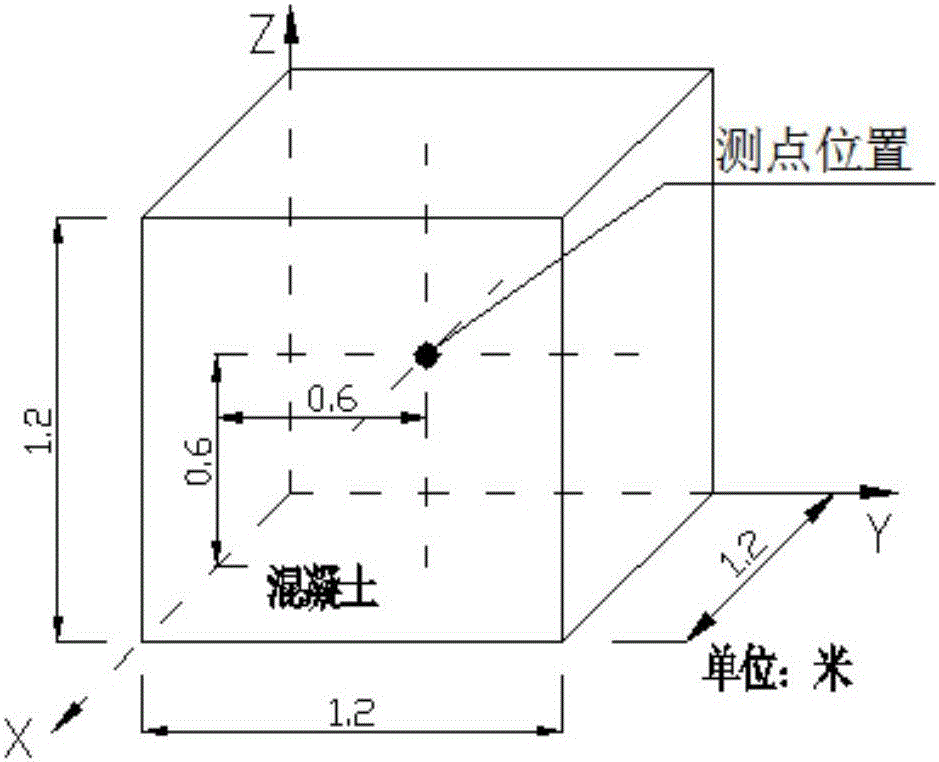

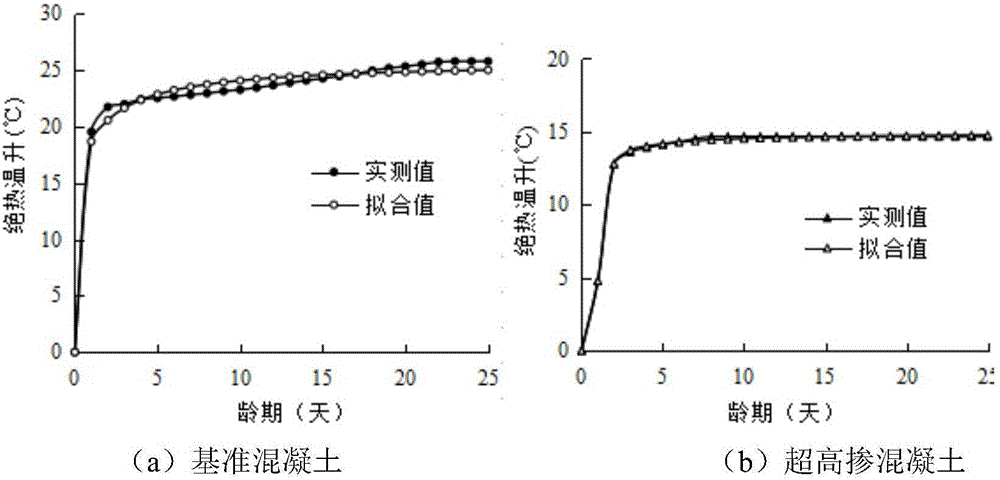

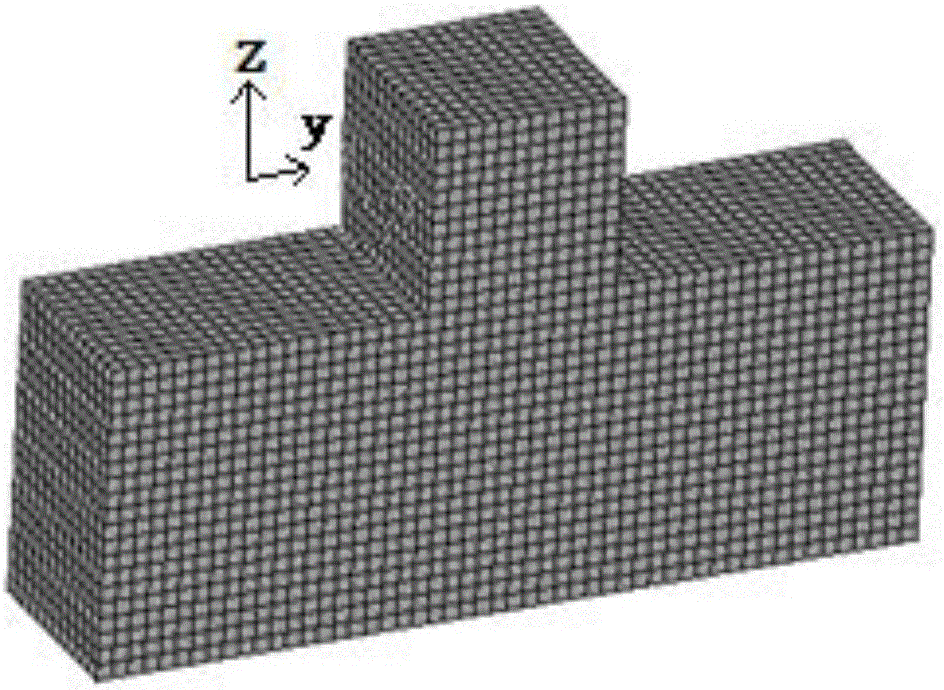

[0043] 1. "Ultra-high concrete" test

[0044] 1.1 Test raw materials and mix ratio

[0045] Two kinds of concrete were prepared in this test, and the "reference concrete" used the dam concrete raw materials and construction mix ratio of double curvature arch dam A. Two kinds of concrete with different fly ash content "baseline concrete" (35% fly ash content) and "ultra-high concrete" (80% fly ash content). The raw materials used in the test are those used in the double curvature arch dam A: Huaxin ordinary 42.5 Portland cement, Jingmen III grade fly ash, the fine aggregate is artificial sand, and the coarse aggregate is artificial crushed stone with a maximum aggregate particle size of 40mm. Its mixing ratio is shown in Table 1:

[0046] Table 1 Mixing ratio of dam concrete with two different fly ash content

[0047]

[0048] 1.2 Test

[0049] (1) Make adiabatic temperature rise specimens of two types of fly ash concrete, and test the adiabatic temperature rise curves o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com