A linear temperature sensing cable

A temperature-sensing detection and cable technology, applied in the field of online temperature-sensing detection cables, can solve the problems of hard temperature-sensing detection cables, inconvenient construction, local point contact phenomenon of NTC characteristic plastic layer, etc., and reduce the risk of accidental damage probability, reducing the effect of short-circuit contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

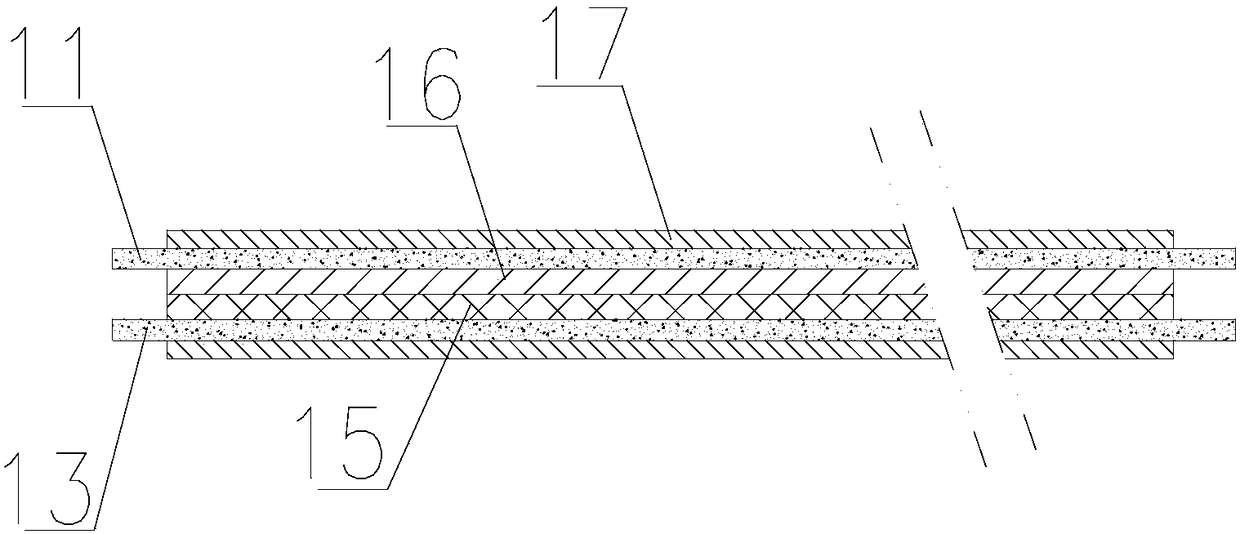

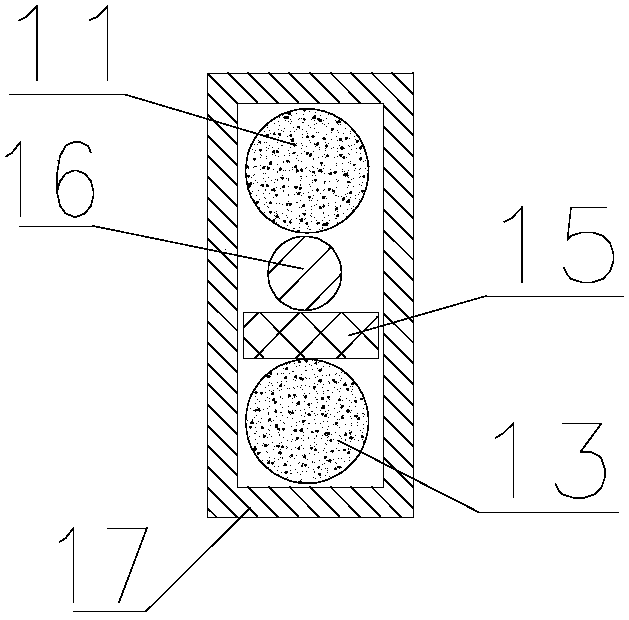

[0039] Such as figure 2 , 3 As shown, it is a schematic diagram of the axial structure and cross-sectional structure of one of the parallel linear temperature-sensing detection cables provided in this embodiment. The signal processing unit (not shown in the figure) and the terminal resistance (not shown in the figure) at both ends of the temperature detection cable; the linear temperature detection cable is mainly composed of two axially superimposed parallel mesh insulation Layer 15 and fusible conductor 16 are composed of detection conductors 11 and 13 together, and a closed outer sheath 17 covering them. Wherein the resistance value R of the terminal resistor is preferably 100Ω˜20MΩ.

[0040] Now the working principle of the linear temperature-sensitive fire detector provided by the present invention is set forth as follows:

[0041] Under normal circumstances, that is, when there is no fire or failure, the fusible conductor 16 is also intact, and when the detection con...

Embodiment 2

[0052] In order to solve the problem that the detector in the first embodiment cannot detect the detection conductor 11 and cannot detect the open circuit fault, the structure of the above-mentioned linear temperature-sensing detection cable is further improved, and the specific description is as follows:

[0053] Such as Figure 11 As shown, it is a schematic diagram of the cross-sectional structure of the parallel linear temperature detection cable provided in this embodiment. The linear temperature detection cable includes a linear temperature detection cable and signals connected to both ends of the linear temperature detection cable Processing unit (not shown in the figure) and terminal resistance (not shown in the figure); wherein the linear temperature detection cable is mainly composed of two detection conductors 11 and 13 arranged in parallel, between which the axial direction is sequentially superposed. It consists of a mesh insulating layer 15' parallel to it, a fus...

Embodiment 3

[0058] In order to solve the problem that the detectors in Embodiments 1 and 2 are still unable to distinguish the two situations of short circuit and fire, the linear temperature-sensing detection cable with the structure described in Embodiments 1 and 2 is further improved, as follows:

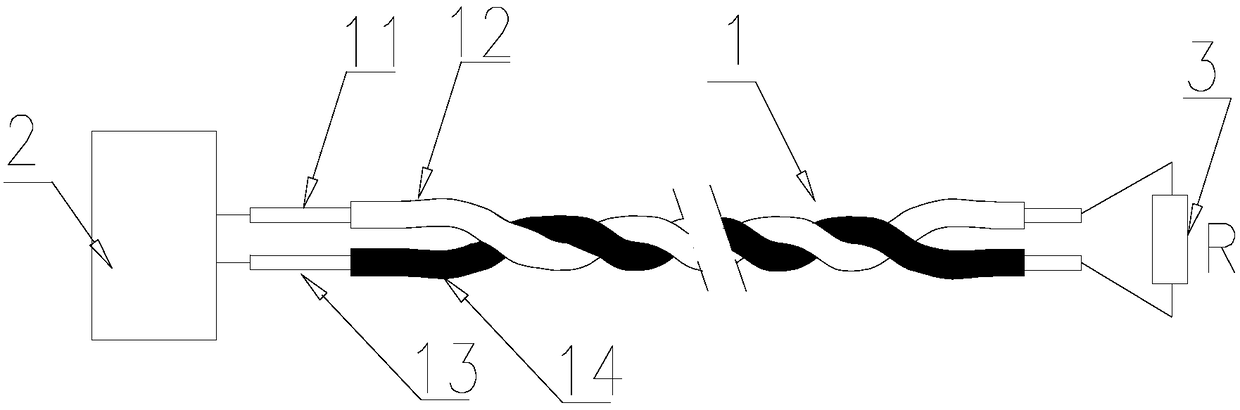

[0059] Such as Figure 14 , 15 As shown, it is a schematic diagram of the axial structure and cross-sectional structure of one of the stranded linear temperature-sensing detection cables provided in this embodiment. The signal processing unit (not shown in the figure) and the terminal resistance (not shown in the figure) at both ends of the temperature detection cable; wherein the linear temperature detection cable is mainly composed of a semiconductor barrier layer 18, a mesh insulating layer The detection conductor 13 of 15 is twisted together with the detection conductor 11 and the fusible conductor 16, and is composed of a closed outer sheath 17 covering it. Wherein, the resistance val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com