Temperature controller for micro motor

A technology for temperature controllers and micro motors, applied in the direction of casing/cover/support, cooling/ventilation devices, electrical components, etc. Problems such as the use effect of the motor, to achieve the effect of easy replacement and maintenance, increased difficulty, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

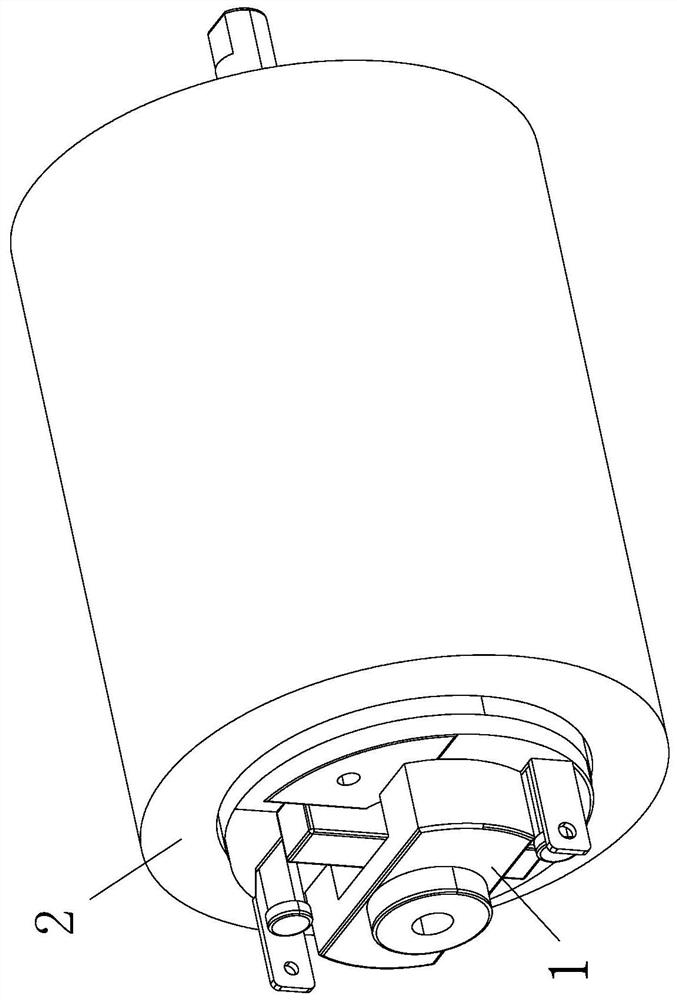

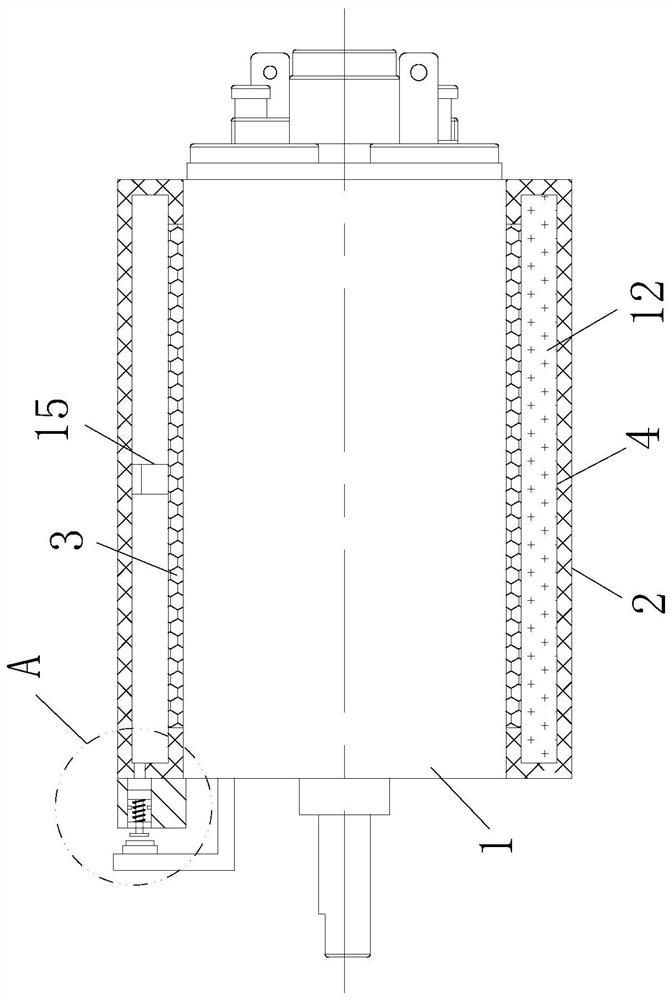

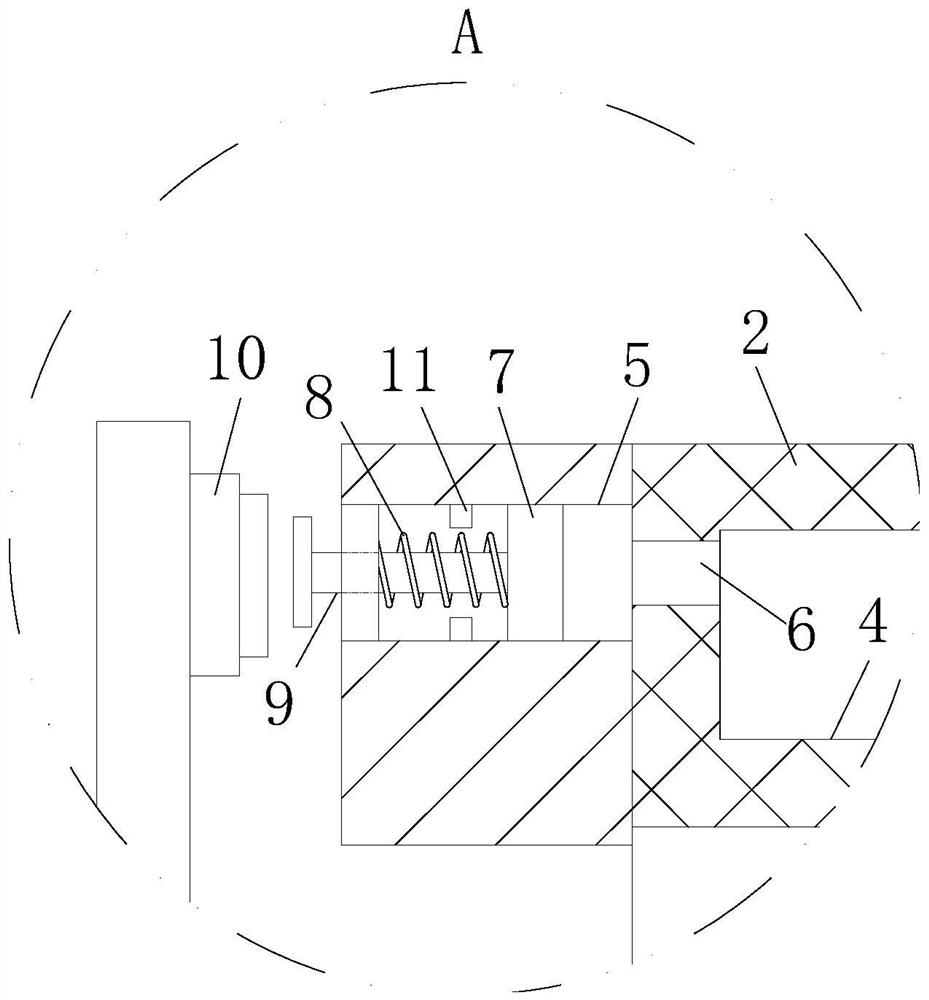

[0029] see Figure 1-5 As shown, a temperature controller for a micro motor according to the present invention includes a motor body 1; A heat conduction layer 3 is provided on the side wall of the protective cover 2, a cavity 4 is opened inside the protective cover 2, a sliding cavity 5 is connected to one end of the protective cover 2, and a sliding cavity 5 is connected to the end of the protective cover 2, which is connected to the inner end of the sliding cavity 5. The airflow hole 6 through which the slide chamber 5 is slidably connected to the slide block 7, the side wall of the slide block 7 fits the inner wall of the slide chamber 5, and the gap between the slide block 7 and the end of the slide chamber 5 An elastic member 8 is connected, and the end of the slider 7 away from the airflow hole 6 is connected with a push rod 9, and the motor body 1 corresponding to one side of the push rod 9 is connected with a touch switch capable of controlling the operation of the mo...

Embodiment 2

[0038] see Figure 6 As shown, the inside of the slide bar 21 is provided with an oil storage chamber 25, the bottom end of the oil storage chamber 25 is slidably connected with a pressure block 26, and there is an elastic connection between the pressure block 26 and the bottom end of the oil storage chamber 25. body 27, a group of oil outlet holes 28 are provided at the position where the top of the sliding rod 21 corresponds to the side wall of the impact block 17, and a lubrication groove is provided at the position where the top of the expansion block 20 fits with the sliding rod 21, so The inside of the lubricating groove is connected with a support pipe 29, and the end of the support pipe 29 close to the slide bar 21 is filled with an absorbing block 30 of water-absorbing material; during operation, lubricating oil is pressed into the oil storage chamber 25 in advance, and when the expansion block 20 The top pushes the impact block 17 on the slide bar 21 to move upward u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com