Probe for ultrasonic inspection of pressurized water reactor fuel assembly and manufacturing process thereof

A fuel assembly, ultrasonic inspection technology, applied in the fields of reactors, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of strong reflective fission product leakage, cladding damage, cladding creep and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

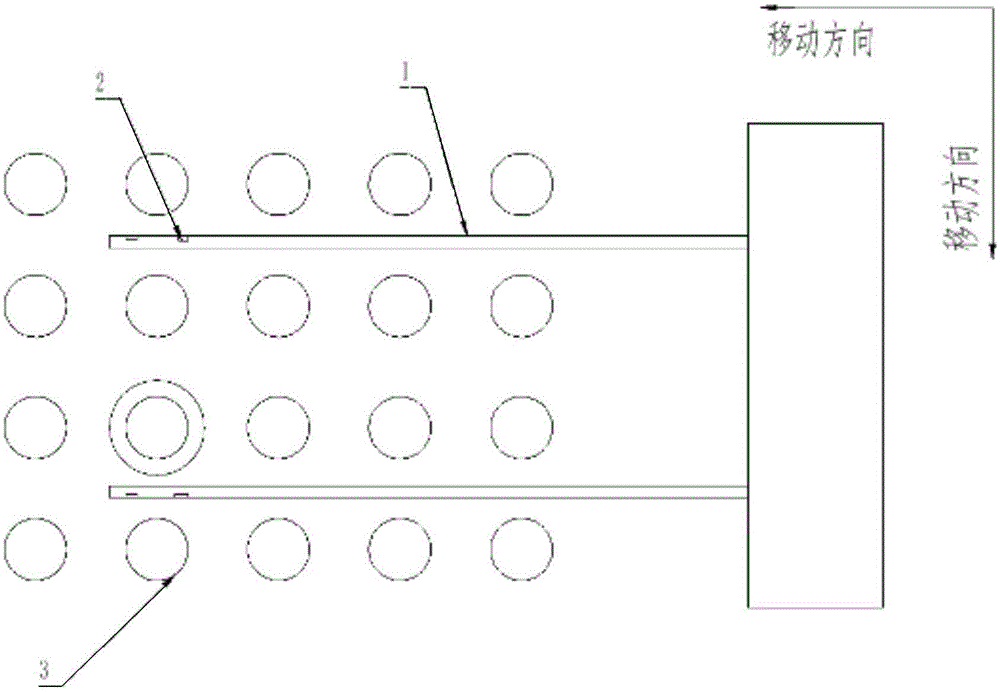

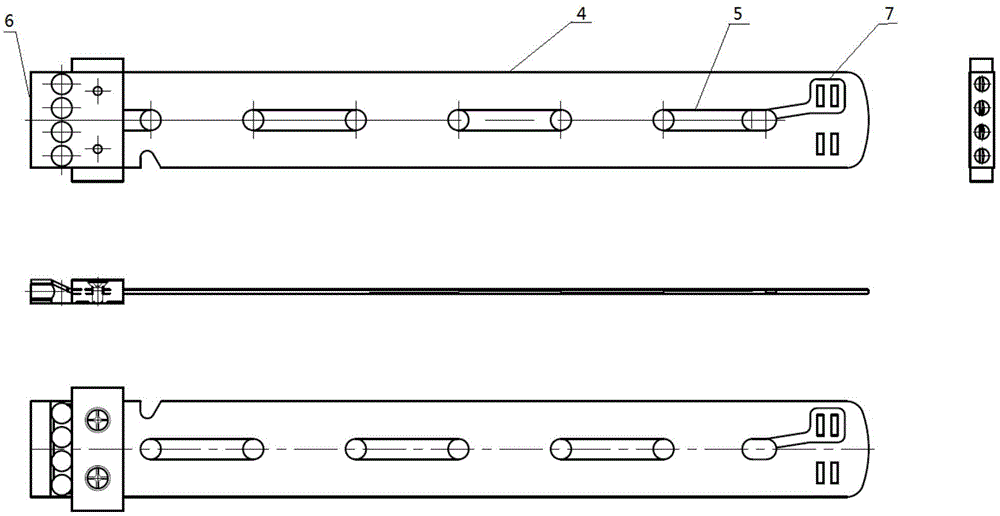

[0021] like figure 2 , image 3 As shown, the probe for ultrasonic inspection of pressurized water reactor fuel assemblies according to the present invention includes a probe bracket 1 and an ultrasonic probe unit 2; the probe bracket 1 includes a substrate 4, a lead groove 5, a socket mount 6 and a probe mounting hole 7, The substrate 4 is provided with a lead slot 5 and a probe mounting hole 7, and the substrate 4 is connected with the socket mounting seat 6 by screws; the probe bracket 1 can simultaneously install two ultrasonic probe units 2. The ultrasonic probe unit 2 is installed in the probe installation hole 7, and the lead cable of the ultrasonic probe unit 2 is connected to the socket mounting seat 6 through the lead slot 5, and then connected to the ultrasonic instrument through an external cable.

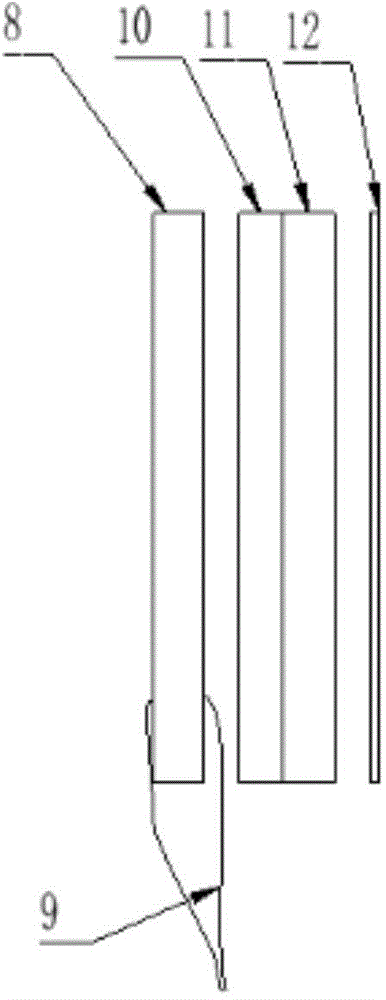

[0022] The ultrasonic probe un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com