A split heating platform for cavity in-line metal packaging

A metal-encapsulated, split-type technology, applied in the manufacture of electrical solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of low heat transfer efficiency, narrow slot structure, affecting production progress, etc., to ensure heat transfer efficiency. , The effect of high heat transfer efficiency and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]Below in conjunction with accompanying drawing, the present invention is described in further detail:

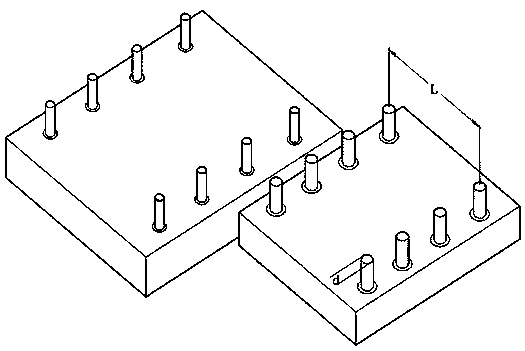

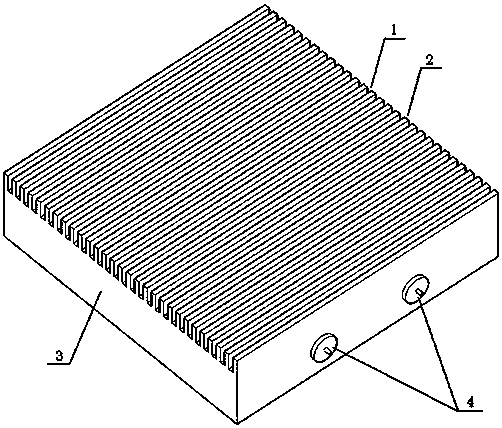

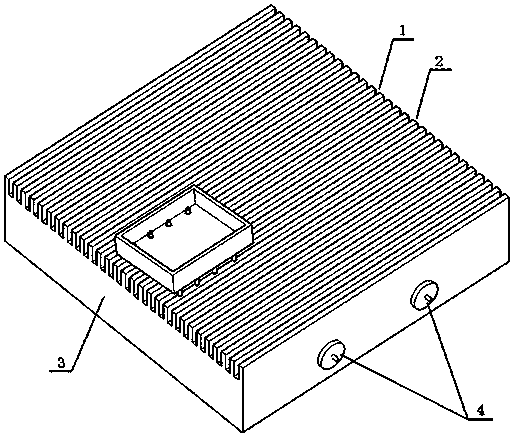

[0039] Such as Figure 4 As shown, a split-type heating table for cavity in-line metal packaging, the split-type heating table consists of a middle joint frame 5, a heat conduction module 6 located in the middle joint frame 5, and a heat transfer module located at the bottom of the middle joint frame 5 Composed of a heating seat 7 for heating the heat conduction module;

[0040] Such as Figure 4 , 5 As shown, the middle joint frame 5 plays the role of up and down connection, and the middle joint frame 5 is processed into a rectangular frame structure, including two sets of corresponding frame edges, wherein, the first set of corresponding frame edges are processed from top to bottom for The first card station 9 carrying the heat conduction module, such as Figure 4 As shown, the two ends of the thermal conduction module 6 are overlapped on the first clamping platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com