Automatic insulator maintenance method for use in power transmission and distribution system

An automatic maintenance and insulator technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high safety risk, complex placement process, and insufficient automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

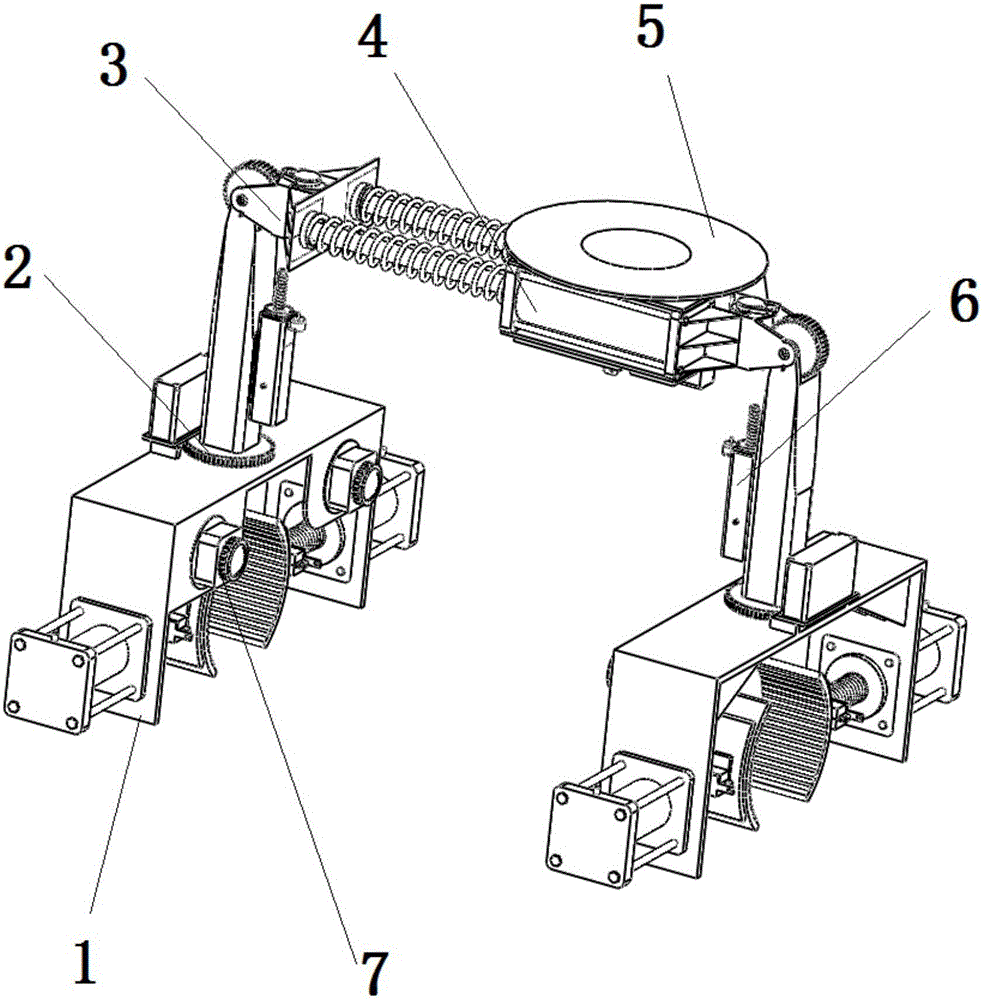

[0087] like figure 1 Shown:

[0088] Automatic maintenance method for insulators in power transmission and distribution system, including

[0089] (2) A maintenance robot for insulators in power transmission and distribution systems;

[0090] (3) Utilize the insulator maintenance robot of the power transmission and distribution system to maintain the insulator;

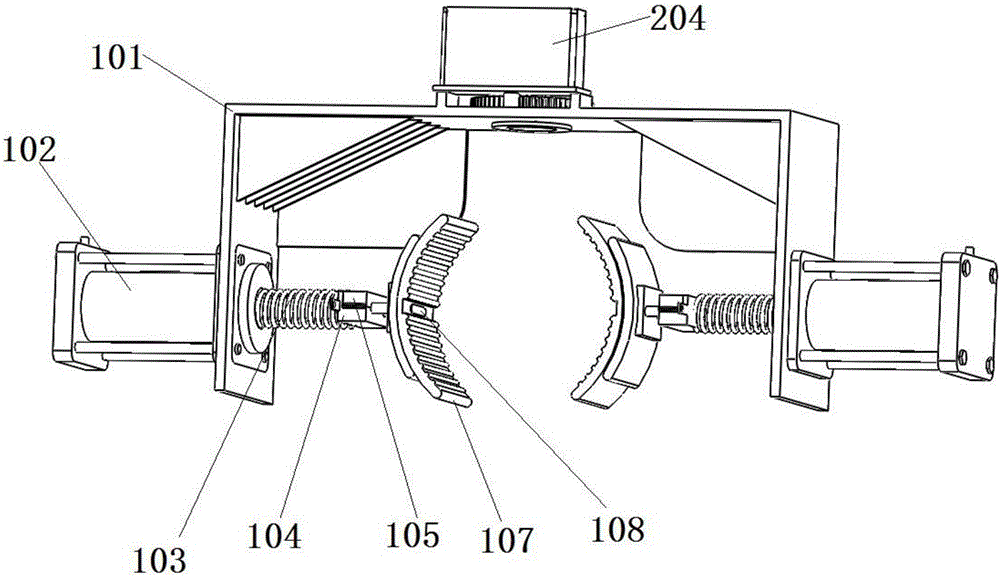

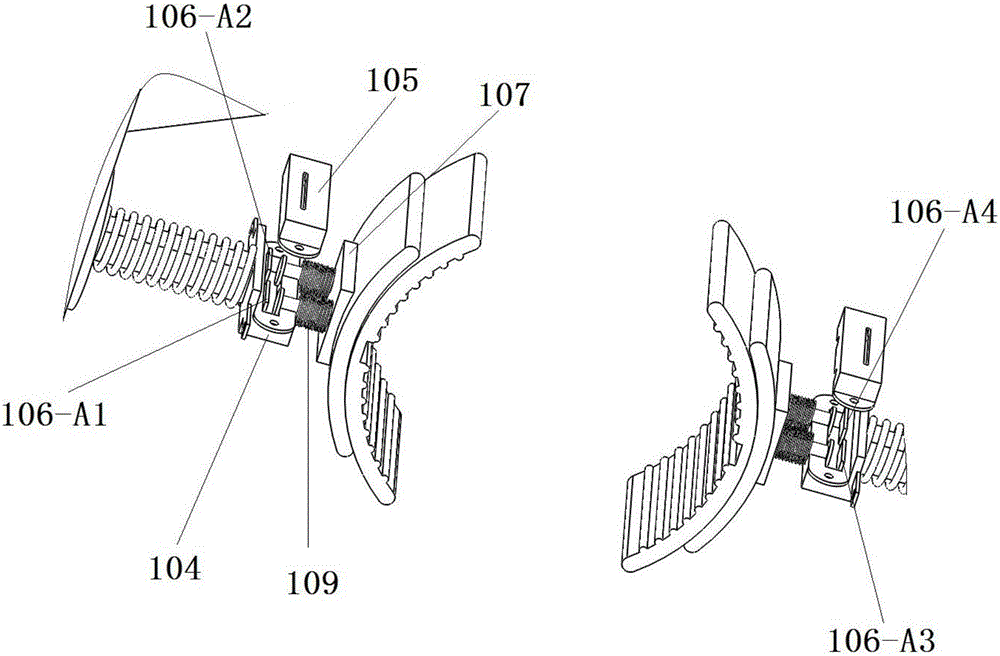

[0091] Among them, the power transmission and distribution system insulator maintenance robot includes a fixed part 1, an adjustment part 2, a right-angle part 3, a telescopic part 4, a positioning part 5, a hydraulic power part 6, a monitoring part 7, a control part 8 and an airborne device 9. Two sets of fixing part 1 , adjusting part 2 and right-angle part 3 are connected with the front and rear ends of telescopic part 4 . The fixing part 1 is connected to the adjusting part 2 , and the fixing part 1 rotates relative to the right-angle part 3 through the adjusting part 2 . The right-angle part 3 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com