High voltage transmission line press-bending deicing method and device

A technology of high-voltage transmission lines and running devices, which is applied in the installation of cables, electrical components, overhead installations, etc. It can solve the problems of wire fatigue damage, endangering lines, and unstable deicing effects, etc., to achieve energy saving, low energy consumption, Stable deicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

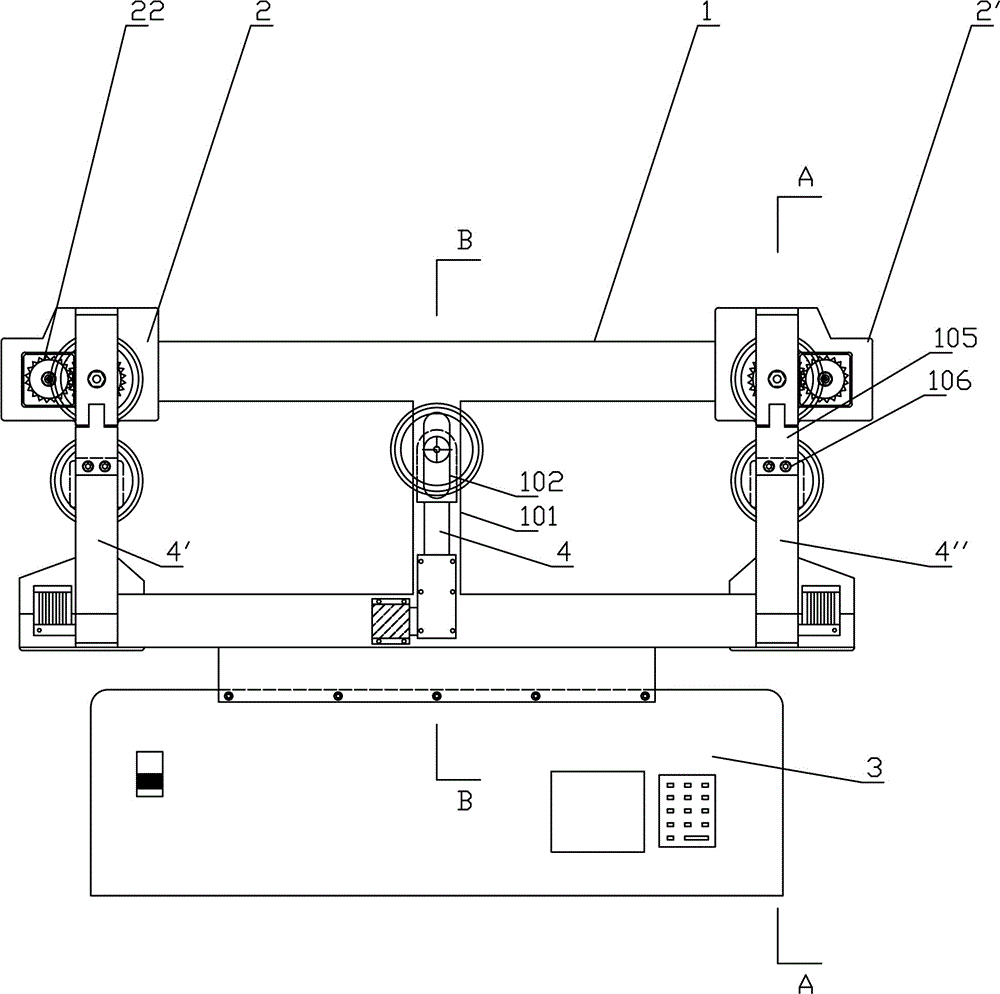

[0041] Such as Figure 1~7 1. A high-voltage transmission line bending deicing method in 9, comprising the following steps:

[0042] 1. A running device hanging on the high-voltage transmission line 5 is provided at both ends of the frame 1, and the whole deicing device can walk along the high-voltage transmission line 5 through the running device;

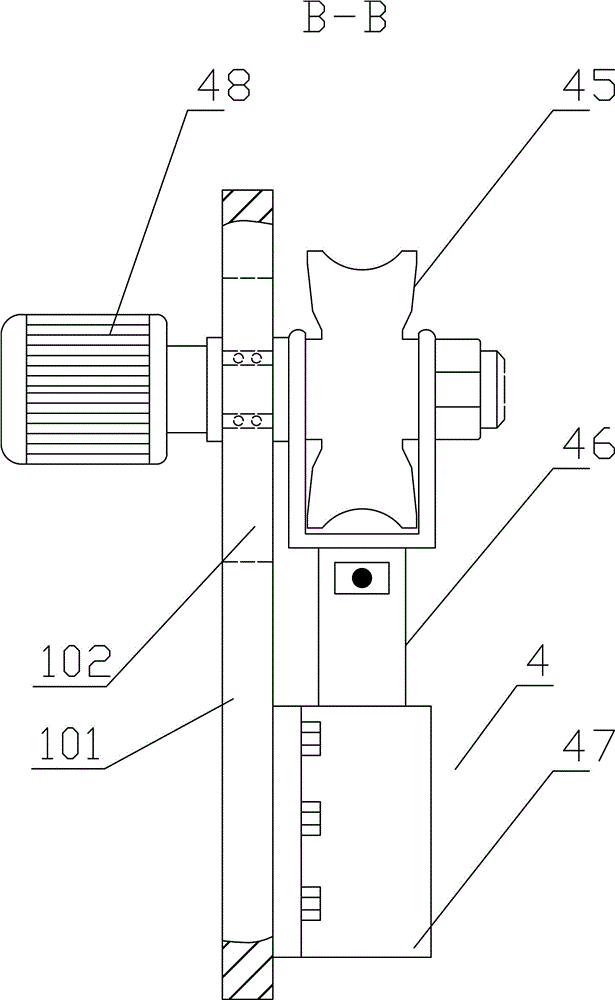

[0043] 2. A liftable ice-breaking wheel 45 is provided in the middle of the frame 1, and the ice-breaking wheel 45 is located below the high-voltage transmission line 5;

[0044] 3. Set the bending height 7 according to the wire type of the high-voltage transmission line 5 and the thickness of the ice layer 6;

[0045] 4. The icebreaker 45 is raised by the control device 3, and the high-voltage transmission line 5 is bent upward to the bending height 7 in a static manner; during the bending process, the ice-coated layer 6 breaks and falls off from the surface of the high-voltage transmission line . As the entire rack assembly t...

Embodiment 2

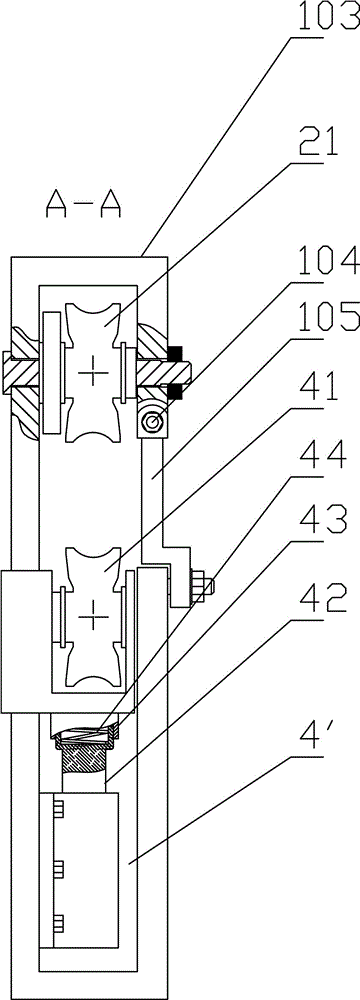

[0051] On the basis of Example 1, such as Figure 1~8 Among them, a device for the above-mentioned high-voltage transmission line bending and deicing method, the two ends of the frame 1 are respectively provided with a first traveling device 2 and a second traveling device 2', and the first traveling device 2 and the second traveling device 2' walking wheels 21 are hung on the high-voltage transmission line 5;

[0052] The road wheels 21 of the first traveling device 2 or / and the second traveling device 2' are connected with the traveling drive device 22; as figure 1Among them, the drive motor of the road wheel 21 is not shown in the figure, the drive motor is fixedly connected with the pinion of the travel drive device 22, the pinion is engaged with the bull gear, and the bull gear is fixedly connected with the road wheel 21 coaxially. The driving motor adopts a DC motor. In this example, a scheme in which the traveling wheels 21 of the first traveling device 2 and the seco...

Embodiment 3

[0064] A more complete deicing procedure is as follows:

[0065] 1. Obtain the wire type of the high-voltage transmission line 5 by consulting the data of the ice-coated line, and the thickness of the ice-coated layer 6 is obtained by the ice-covered monitoring device or manual measurement;

[0066] The bending height 7 is calculated by the finite element method according to the wire type and the thickness of the ice layer 6 when the wire ice layer 6 reaches the crushing bending stress;

[0067] 2. Check whether the structural connection of each component is normal, turn on the power switch of the control device 3, and carry out device debugging;

[0068] And through the keyboard of the control device 3, parameters such as the wire model, the thickness of the ice-coated layer, and the restraint length of the ice-coated wire are input to the system, and the bending height 7 is obtained through calculation;

[0069] 3. Lift the deicing device to the iron tower by means of a pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com