A high-power surface-type permanent magnet synchronous motor optimization control method

A permanent magnet synchronous motor, optimized control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve problems such as inaccurate decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

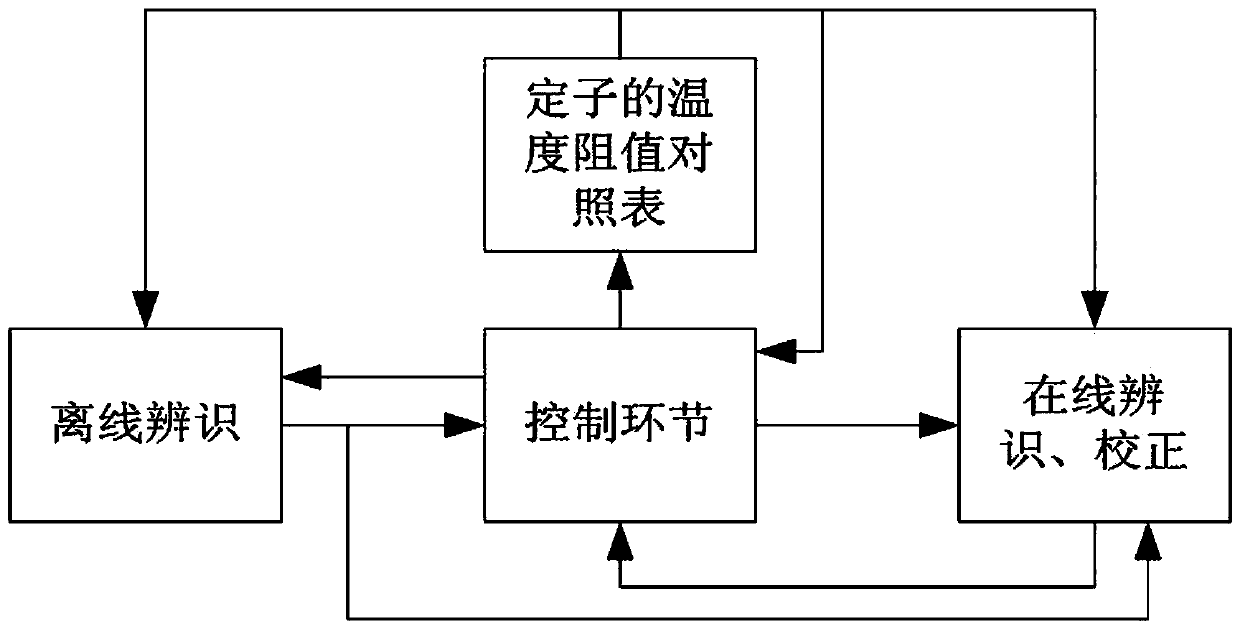

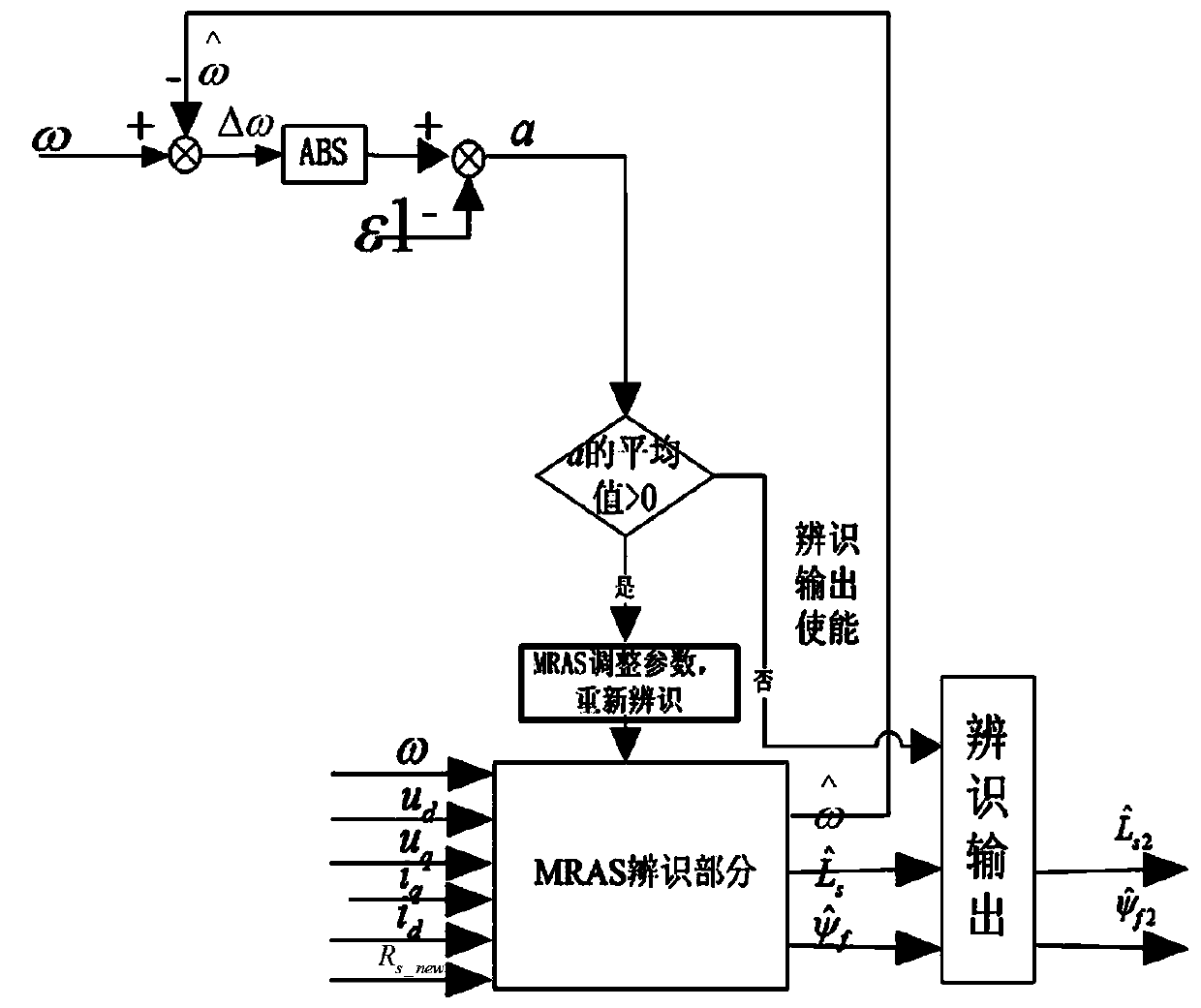

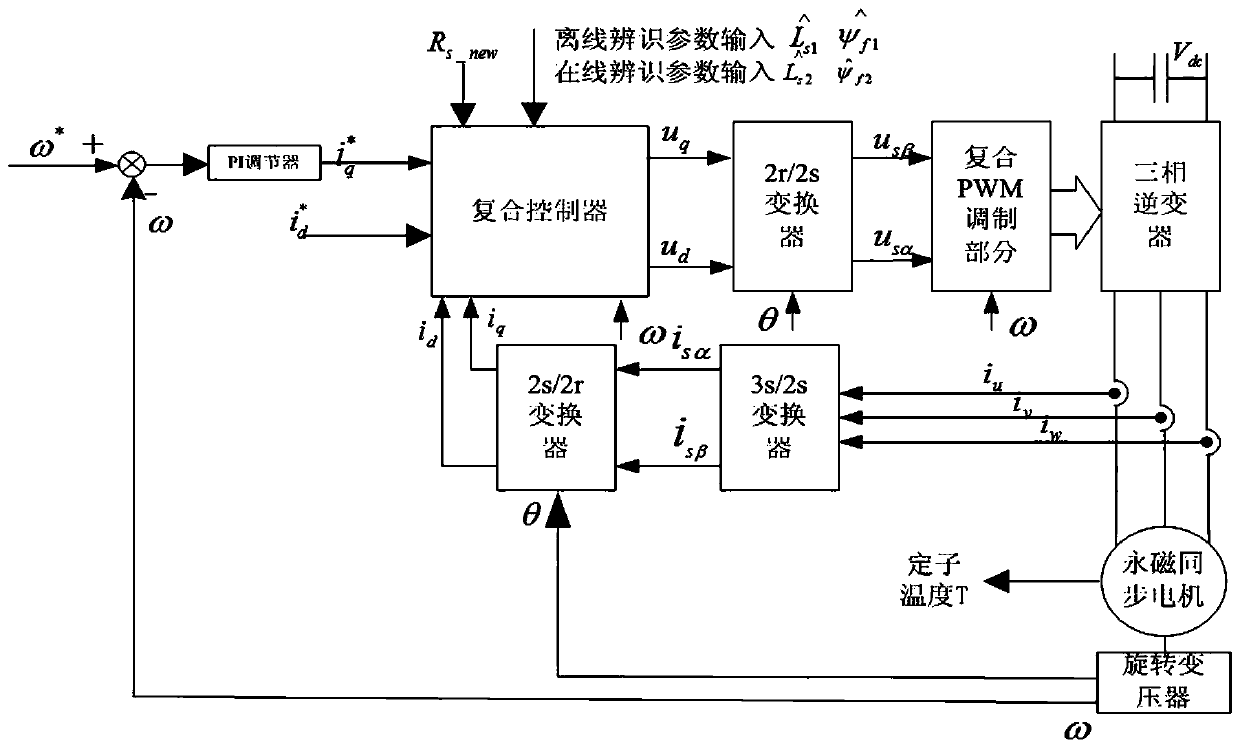

[0053] A high-power surface-type permanent magnet synchronous motor optimization control method, the method is implemented by the following steps:

[0054] Step a runs before step d begins;

[0055] Step b and step c run concurrently with step d after step d starts;

[0056] a. Off-line identification process of parameters:

[0057] a1. At the beginning of offline identification, query the temperature resistance comparison table of the stator according to the stator temperature value T of the permanent magnet synchronous motor acquired in real time, and obtain the stator resistance value R s4 ;

[0058] a2. Off-line identification process of stator inductance:

[0059] Apply a fixed vector voltage to the permanent magnet synchronous motor and maintain the voltage for a certain period of time, thereby positioning the direct axis of the permanent magnet synchronous motor; during the positioning process, the direct axis of the permanent magnet flux linkage of the permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com