Body motion device of a placement machine

A motion device and placement machine technology, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing, can solve the problems of complex assembly and easy wear and tear of body motion devices, and achieve weight reduction, simple structure, and low cost. The effect of assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

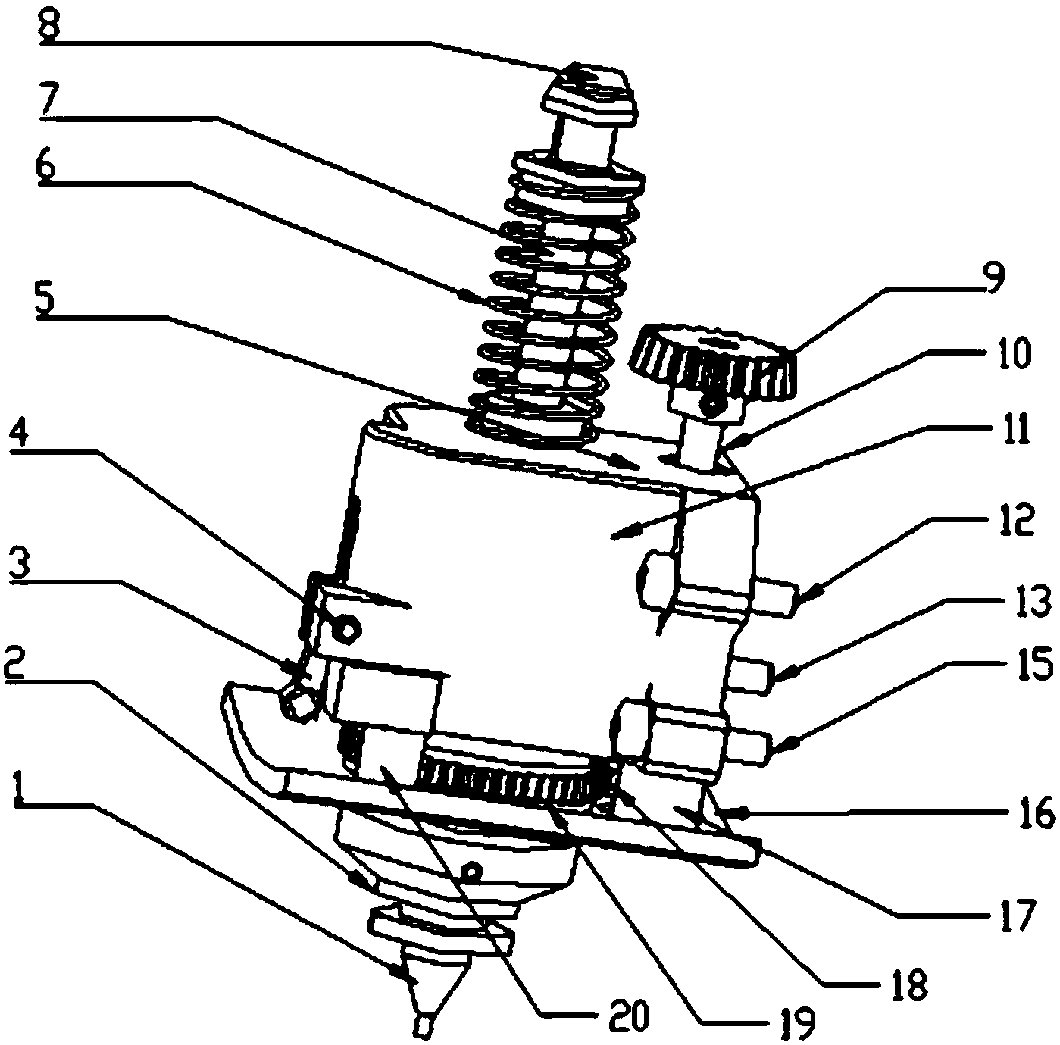

[0025] Such as figure 1 As shown, a body motion device of a placement machine includes a lower supporting plate 16, an installation panel 11, an upper cover plate 5, a vacuum switching module, a longitudinal guide module and a suction nozzle rotation movement module; the upper and lower sides of the installation panel 11 An upper cover plate 5 and a lower supporting plate 16 are installed respectively.

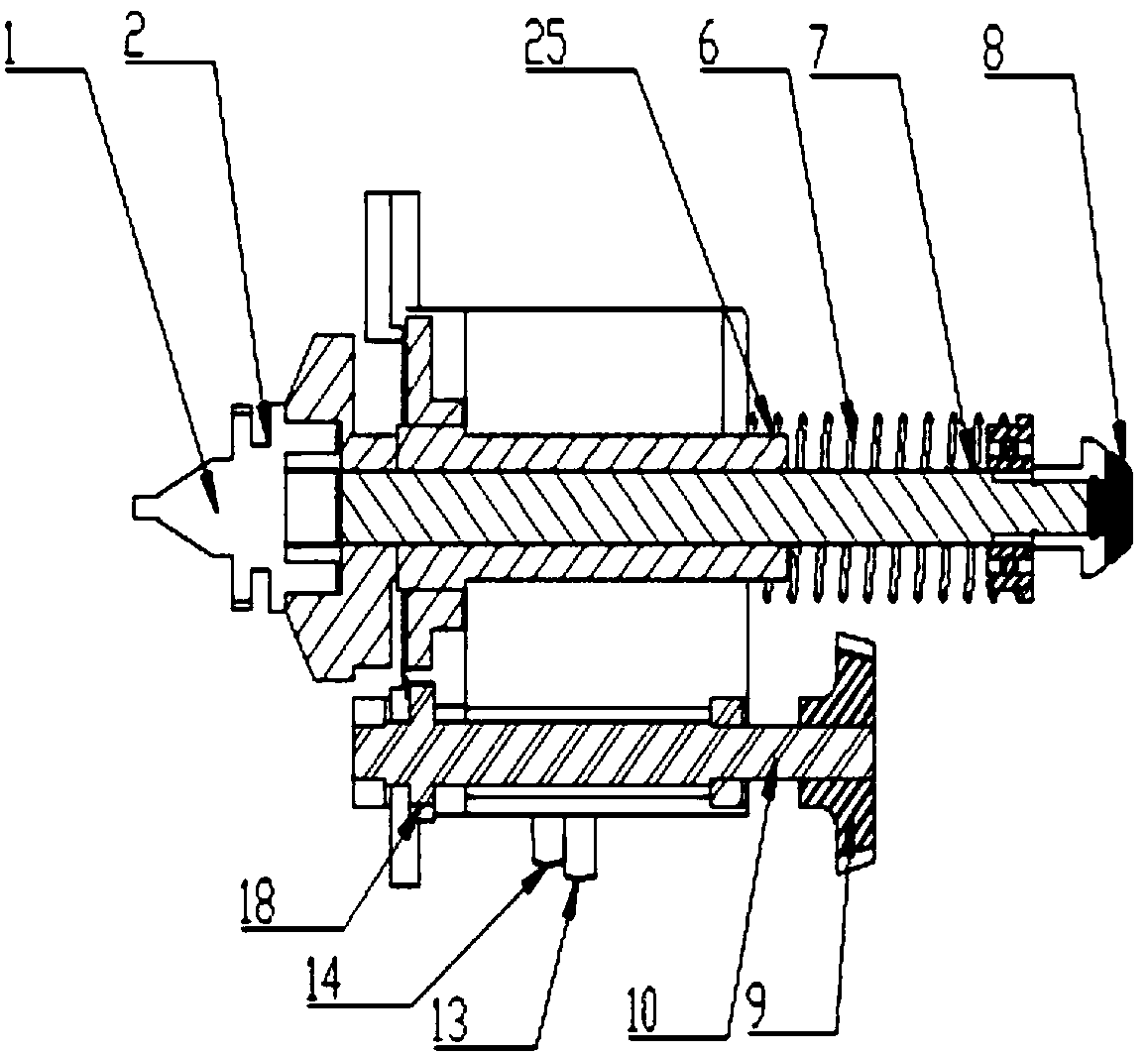

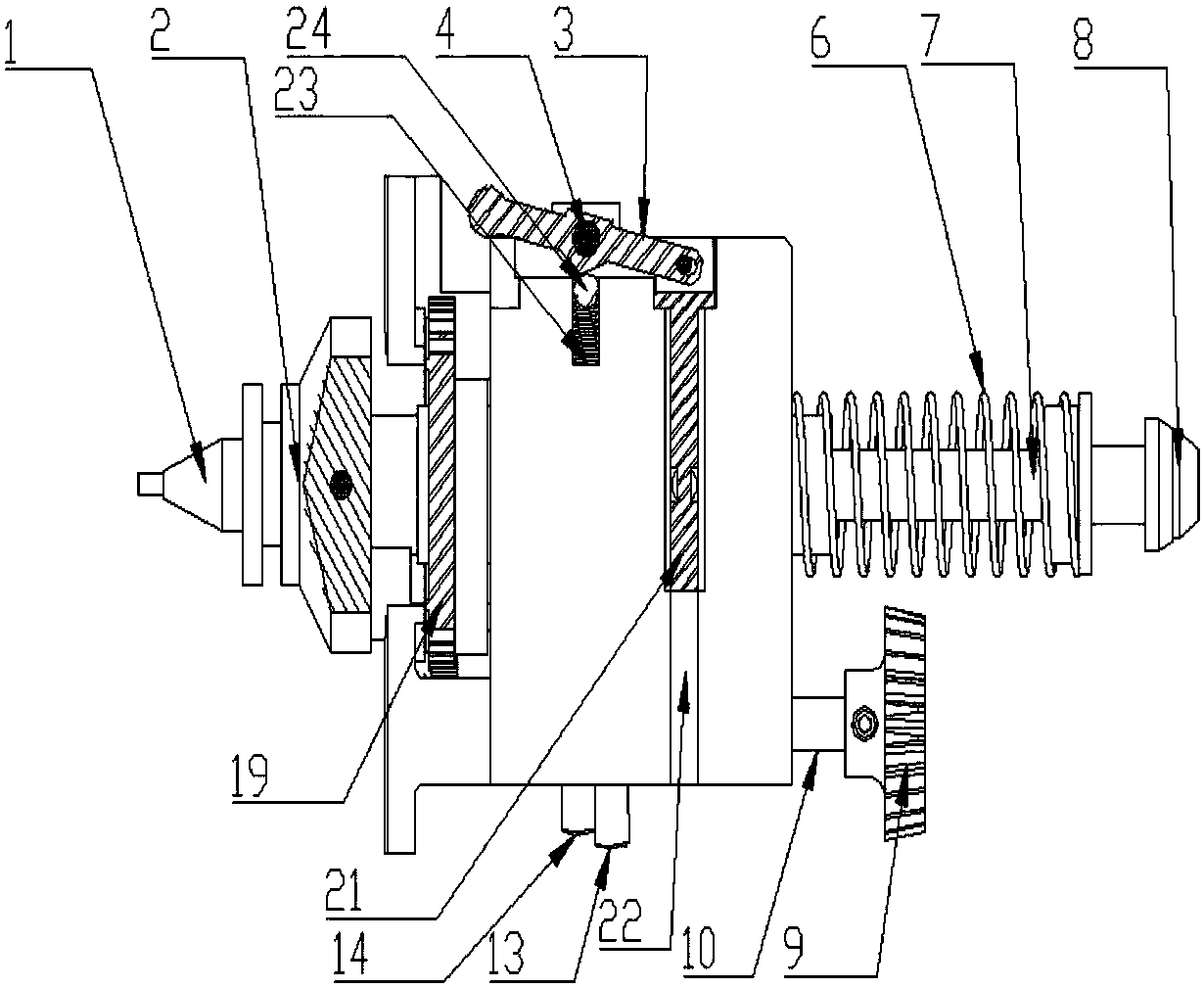

[0026] Such as figure 2 As shown, the longitudinal guide module includes a suction nozzle 1, a nozzle holder 2, a guide rod 7, a long sleeve 25, a first spring 6 and a cam guide 8; the guide rod 7 passes through the upper cover plate 5 in turn and the center hole of the lower supporting plate 16, and the lower end is interference fit with the nozzle holder 2; The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com