Multifunctional industrial control method based on OLT-MFIC01 controller

A technology of industrial control and controller, which is applied in the direction of program control, program control, and comprehensive factory control in sequence/logic controllers. preparatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is currently a terminal controller specially developed for test automation requirements. The stable hardware design can ensure the normal operation of the system for a long time, supports pure hardware timing watchdog, and is suitable for unattended 7X24-hour application environments.

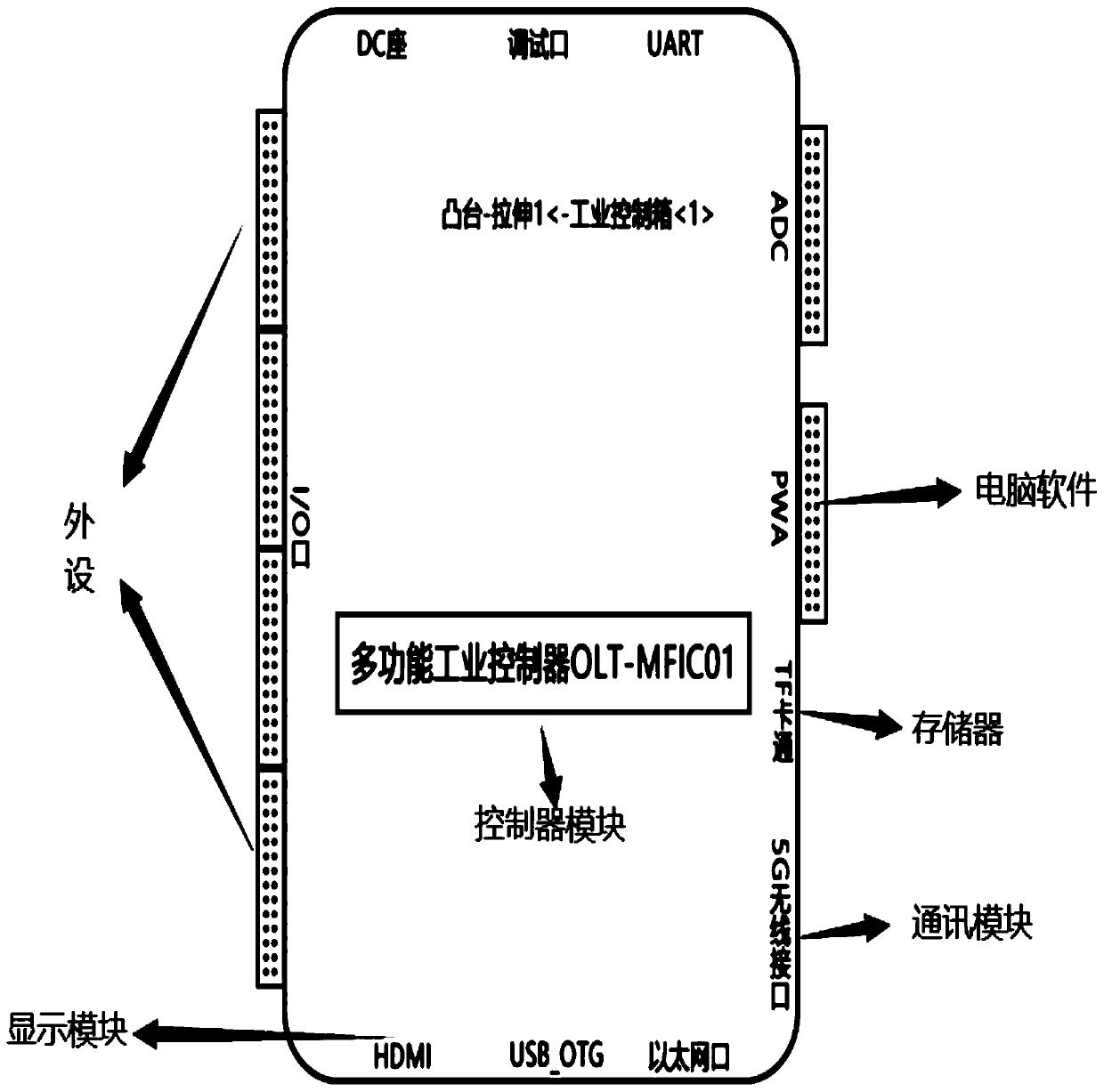

[0028] Such as figure 1 As shown, this product first connects the required peripherals to the controller, and then physically connects the controller to the computer through a USB or network cable, then turns on the computer, uses the software, confirms that it has been connected, and confirms that the controller establishes a data connection with the computer. Then burn the data edited by the software to the controller, the burning is successful, the indicator light flashes, and the controller starts to work after pressing the button.

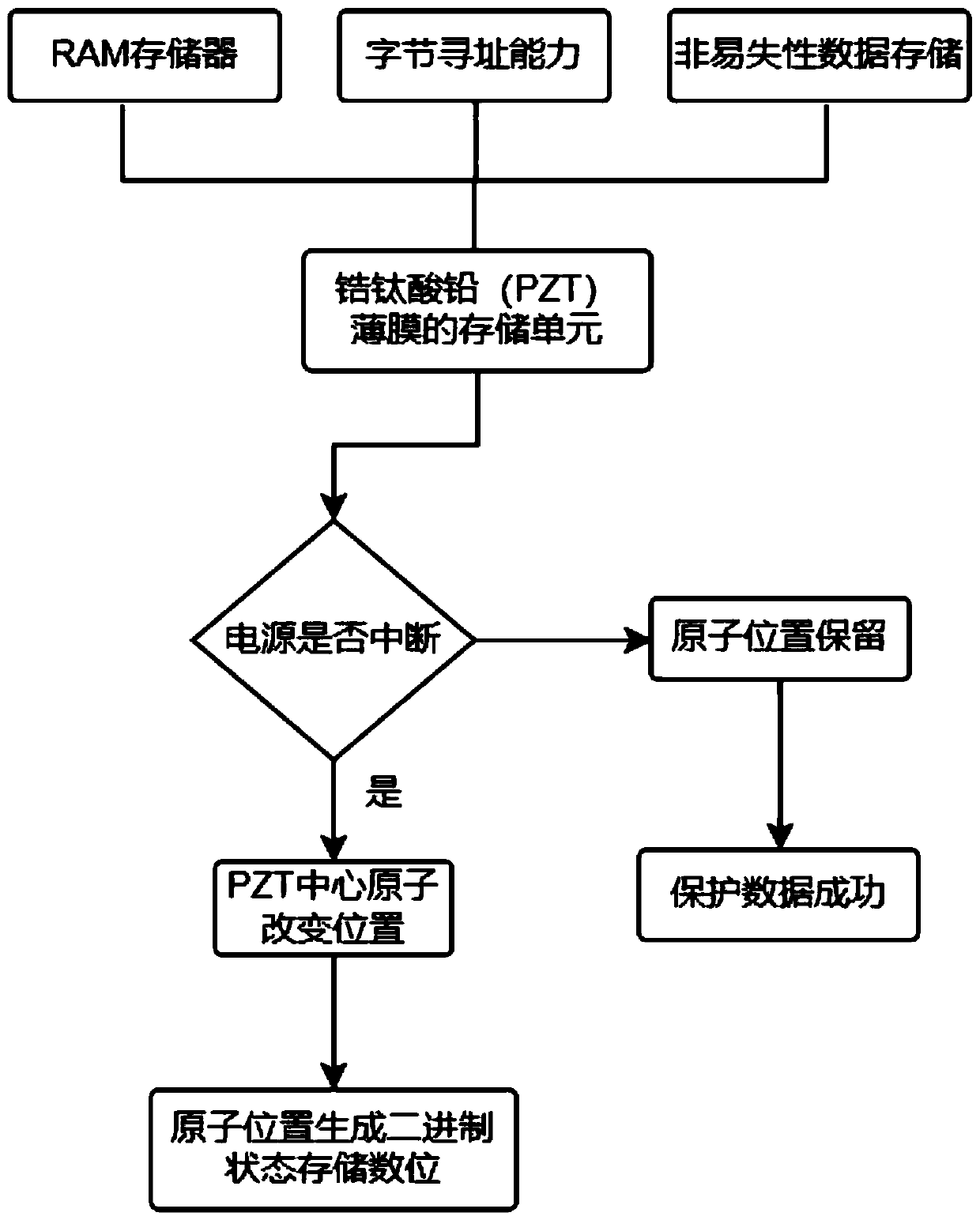

[0029] Such as figure 2 As shown in the figure, after the peripherals are successfully connected and debugged, the reading and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com