Liquid-liquid microextraction oscillation device

An oscillating device and extraction technology, which are used in liquid solution solvent extraction, solvent extraction, extraction water/sewage treatment, etc., can solve the problems of difficult processing, waste of raw materials and bottles, and small oscillation amplitude, and achieve uniform mixing/extraction. And, improve work efficiency, the effect of large oscillation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

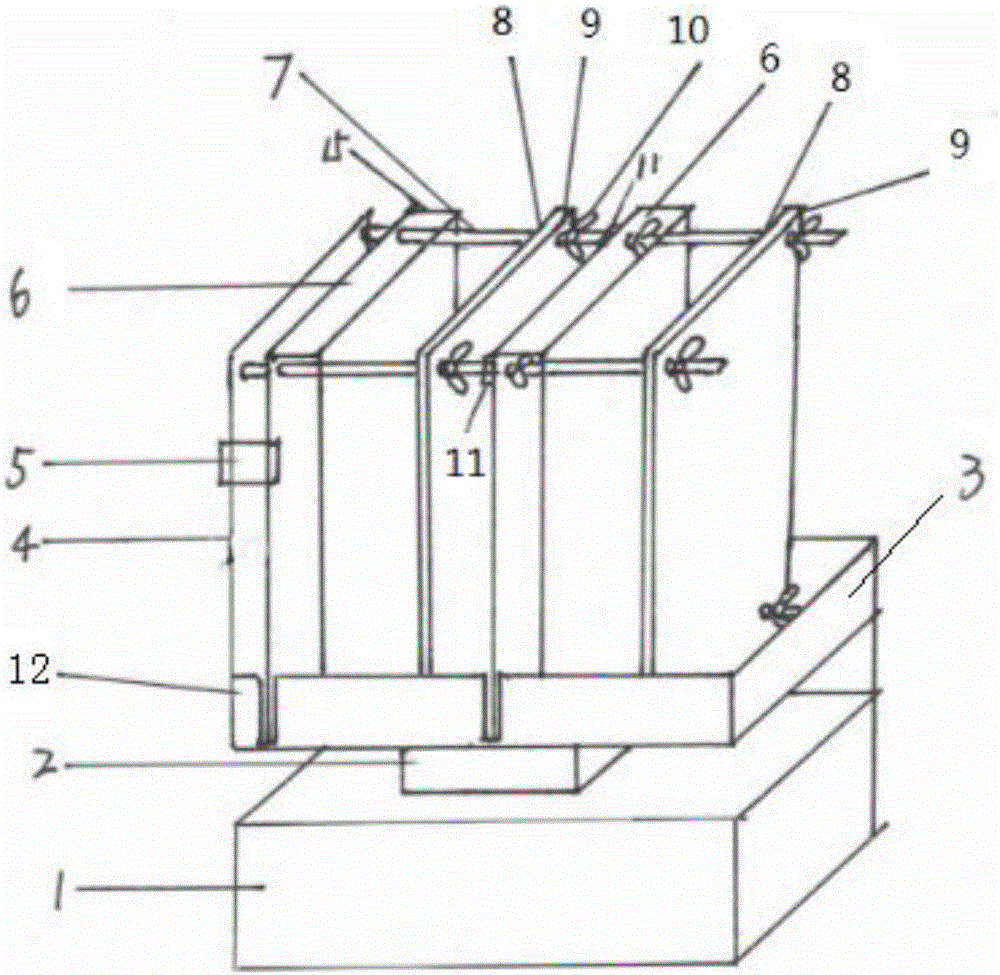

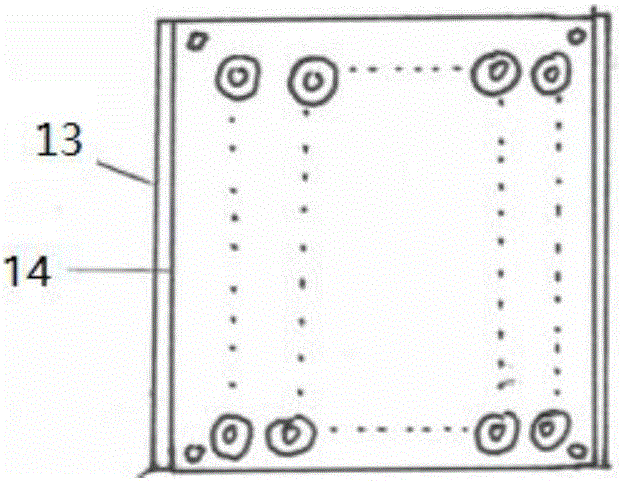

[0022] see figure 1 with figure 2 , the liquid-liquid micro-extraction oscillation device provided by the present invention specifically includes that the oscillation action generated by the motor and the controller 1 is transmitted to the tray 3 through the connector 2, and the tray has 4 chassis that can snap the extraction tube bracket 6 into it. Groove 16, and the side plate on one side, side plate both sides respectively have a fixing clip 5, be convenient to extracting tube bracket 6 and pallet fixing, by fixing four fixing screws 7 on the left side bracket chassis and fixing The nut 10 and the fixed lock nut 11 connect the two sets of extraction tube trays, rubber pads and cover plates together. The chassis of the extraction tube bracket and the fixed plate are connected by 4 metal rods 15. Both sides of the chassis are slightly longer than the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com