System and method for measuring surface tension of metal melt under electromagnetic suspension condition

A metal melt and surface tension technology, applied in the field of material thermophysical properties research, can solve the problems of weak signal, complicated processing process, inconvenient use, etc., and achieve the effect of improving measurement accuracy, high sensitivity, and convenient measurement position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

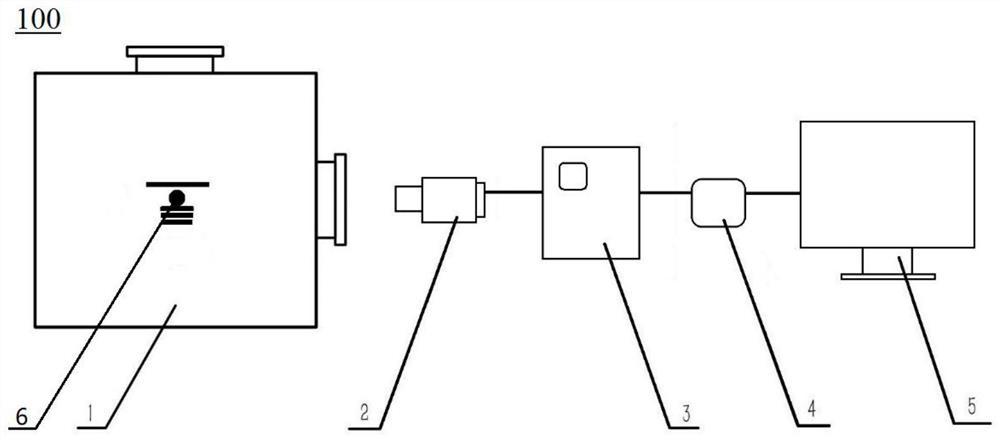

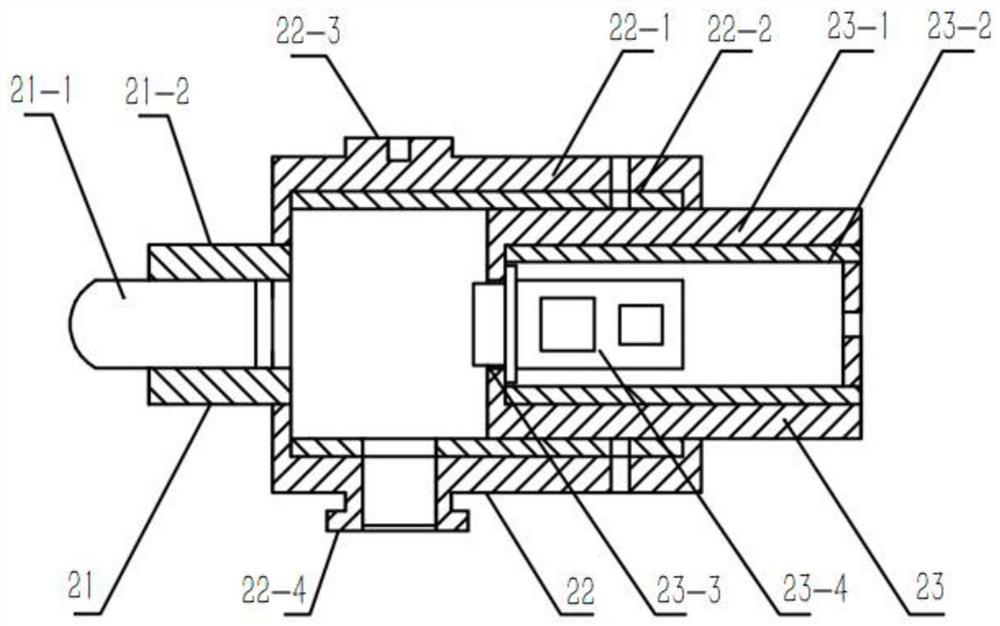

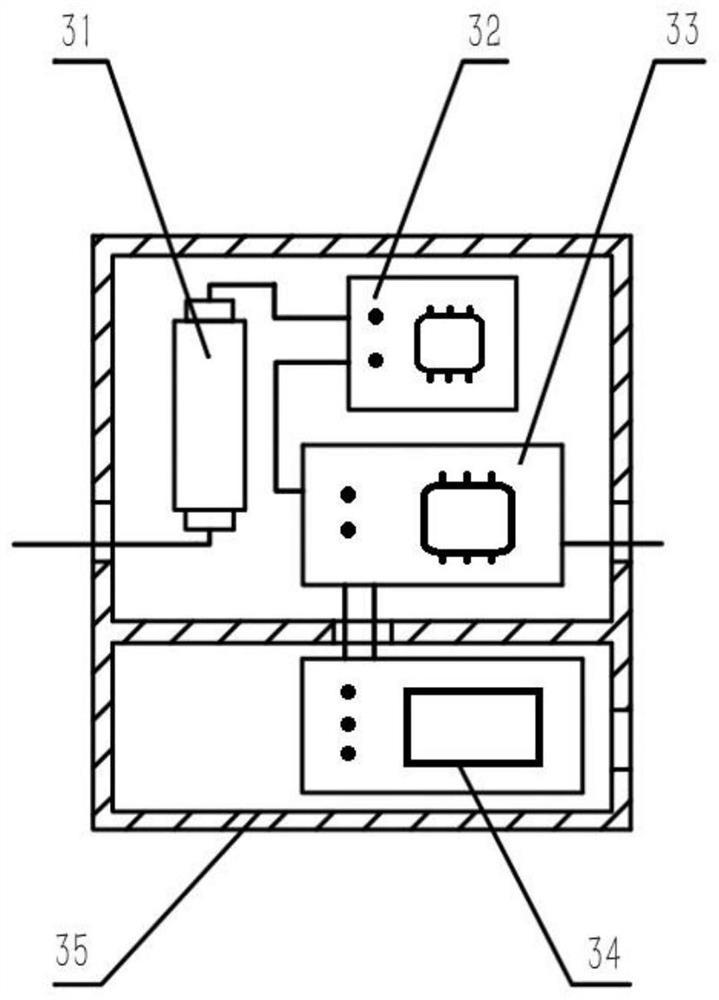

[0048] Such as Figure 1-Figure 3 As shown: this embodiment provides a metal melt surface tension measurement system 100 under the condition of electromagnetic levitation, including a photodetector 2, a filter structure 3, a data acquisition card 4 and a computer signal processing system 5, which are electrically connected in sequence, and a photoelectric The detector 2 is used to collect the light intensity signal of the metal sample 6 in the suspension induction heating device 1. Specifically, the photodetector 2 includes a photoelectric sensor 23, and the photodetector 2 also includes a laser sight 21 or a lens. The photosensitive surface is opposite to the laser sight 21 or the lens. The laser sight 21 is used to aim at the metal sample 6. The lens can maximize the focus of the light emitted by the metal sample 6 onto the photosensitive surface of the photoelectric sensor 23. The photoelectric sensor 23 is used for The collected light intensity signal of the metal sample 6...

Embodiment 2

[0067] This embodiment provides a metal melt surface tension measurement method using the metal melt surface tension measurement system 100 under the electromagnetic levitation condition of Embodiment 1, including the following steps:

[0068] Step 1: Prepare the metal sample 6, the mass of the metal sample 6 is 0.5-5g, use an electric arc furnace or other equipment to melt the metal sample 6 into a nearly spherical shape; put the metal sample 6 into the suspension induction heating device 1, and then conduct the suspension induction heating The heating device 1 is evacuated to 10-3 ~ 10-5Pa, then filled with inert gas, and the gas is repeated 2 to 6 times to provide the atmosphere required for the experiment to the suspension induction heating device 1;

[0069] Step 2: erect and adjust the photodetector 2;

[0070] In step 2, align the photodetector 2 with the window of the suspension induction heating device 1 by using an optical rod, and the distance from the metal sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com