Boiler waste gas processing device

A treatment device, boiler exhaust gas technology, applied in the direction of gas treatment, combined device, membrane technology, etc., can solve the problems of atmospheric environmental pollution, affecting human health, polluting the environment, etc., and achieve the effect of avoiding the waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

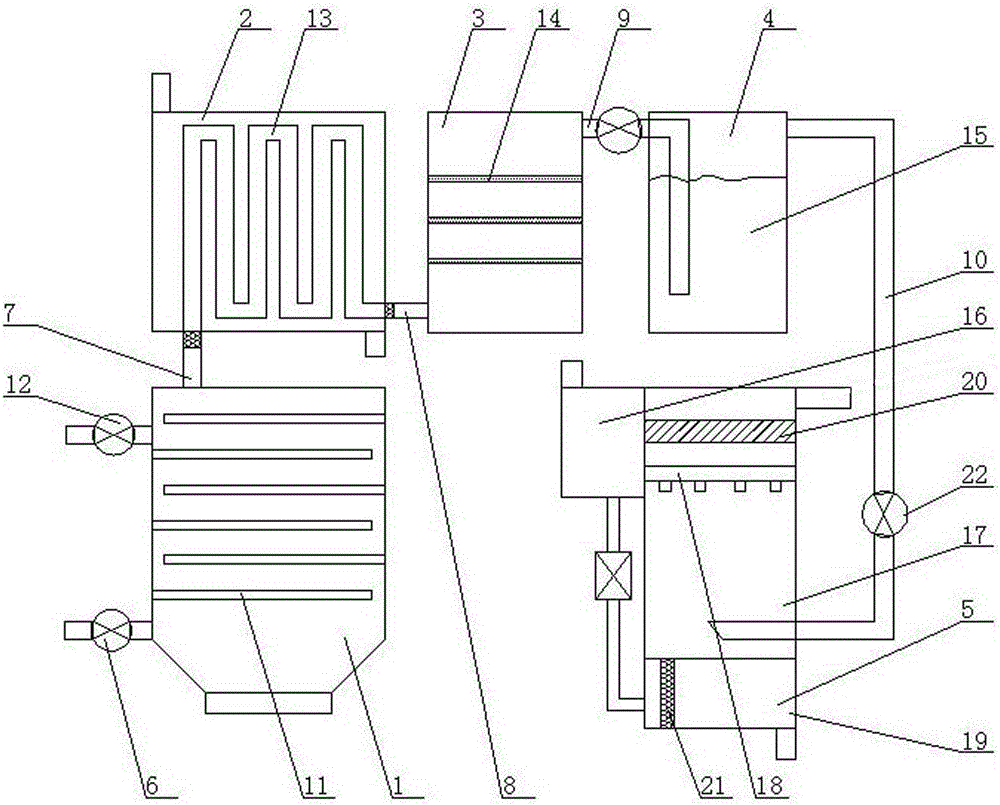

[0019] Such as figure 1 As shown, a boiler exhaust gas treatment device includes a dust removal box 1, a waste heat recovery box 2, an electrolysis box 3, a denitrification box 4, and a spray desulfurization box 5. The left lower end of the dust removal box 1 is equipped with a suction fan 6, and the dust removal The box 1 is connected to the waste heat recovery box 2 through the first air pipe 7 on the left side of the top, and the waste heat recovery box 2 is connected to the electrolysis box 3 through the second air pipe 8, and the electrolysis box 3 is connected to the denitrification box 4 through the third air pipe 9, The denitrification box 4 is connected to the spray desulfurization box 5 through the fourth gas delivery pipe 10 .

Embodiment 2

[0021] Such as figure 1 As shown, the interior of the dust removal box 1 is equipped with a plurality of dust baffles 11, and the plurality of dust baffles 11 are arranged at intervals on the left and right inner walls of the dust removal box 1, and a dust exhaust fan 12 is also installed at the left upper end of the outer wall of the dust removal box 1.

Embodiment 3

[0023] Such as figure 1 As shown, the heat exchange tube 13 and the heating pool are installed inside the waste heat recovery box 2. The heat exchange tube 13 is a curved heat exchange tube 13, and one end of the pipe is connected to the first air pipe 7, and the other end of the pipe is connected to the second air pipe. Air pipe 8; the water inlet pipe is installed on the left side of the top of the waste heat recovery box 2, and the water outlet pipe is installed on the right side of the bottom end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com