Automatic straightening machine for shafts and pipes

A straightening machine and automatic technology, applied in the field of automatic straightening machines for shafts and tubes, can solve the problems of difficult straightening processing, long inspection time, and increase production costs, saving manpower, reducing processing costs, and safe and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

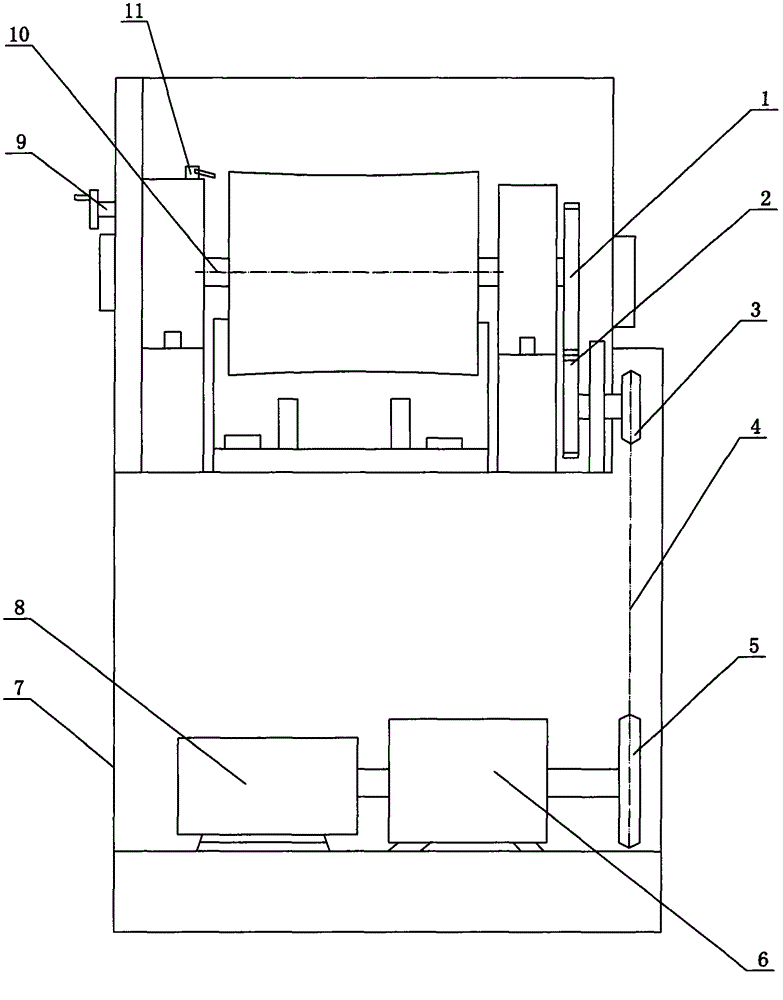

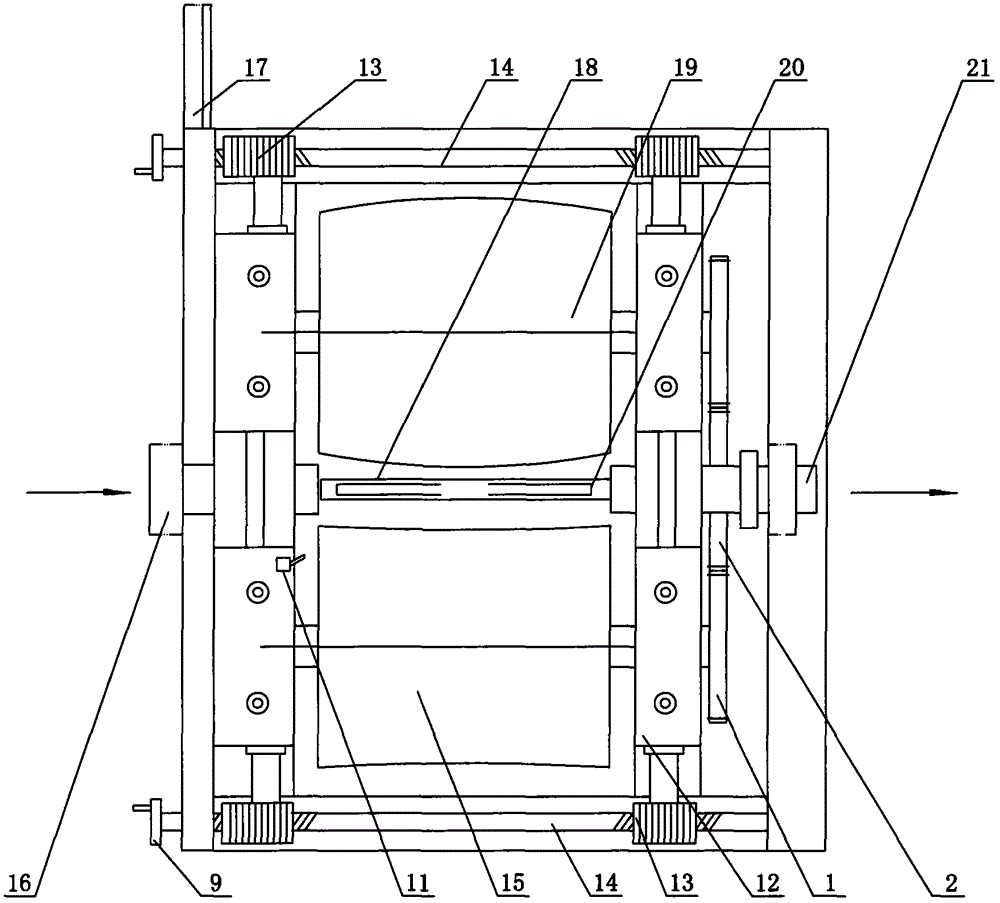

[0011] exist figure 1 , figure 2 Middle: The bed 7 is a cubic shape with mechanical moving parts on it. One side of the bed 7 is provided with a computer control cabinet 17. The computer control cabinet 17 is provided with a display screen and a membrane button, a motor 8 and a deceleration mechanism. 6 are connected, the reduction mechanism 6 is connected with the main sprocket 5, the main sprocket 5 is connected with the driven sprocket 3 through the chain 4, the driven sprocket 3 is connected with the driving gear 2, and the driving gear 2 drives the left and right driven gears 1 are respectively connected with the two main shafts 10; the front and rear sides of the bed 7 are respectively provided with a feed port 16 and a discharge port 21; The worm rods 14 are connected, and a turbine 13 is respectively provided at both ends of the worm rod 14, and a shaft is respectively arranged between the turbines 13 on both sides, and two support blocks 12 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com