High-efficiency automatic numerical control machining center machine tool and operation method thereof

A machining center, high-efficiency technology, used in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve problems such as low efficiency, inability to perform automatic tool change, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

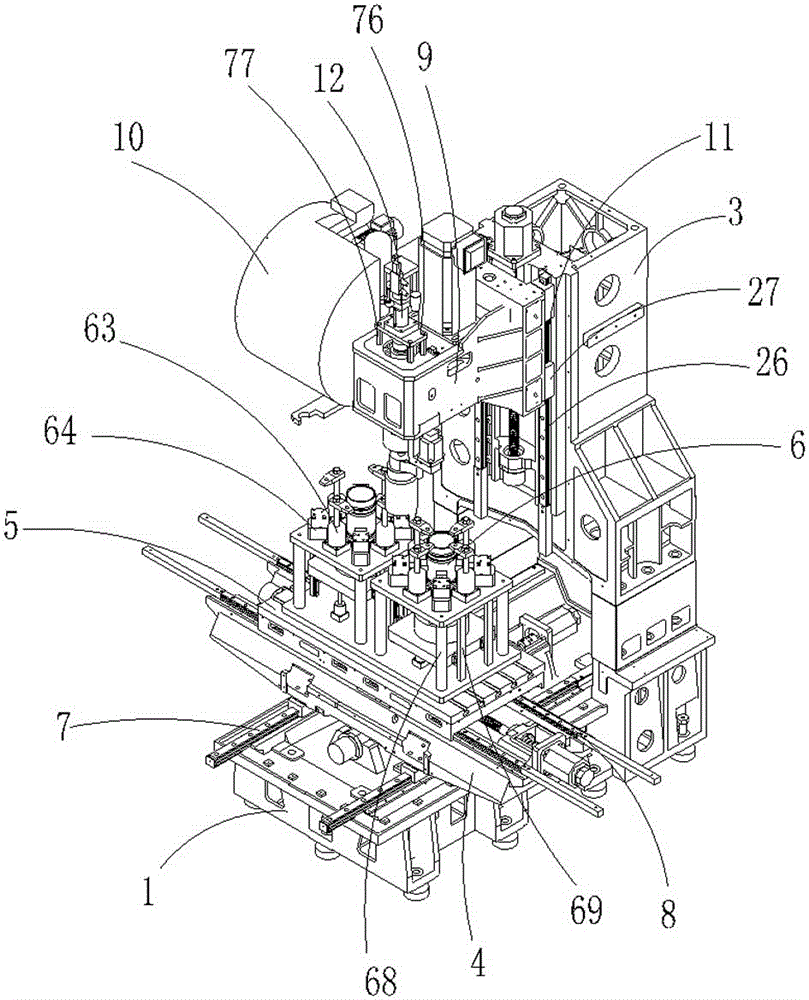

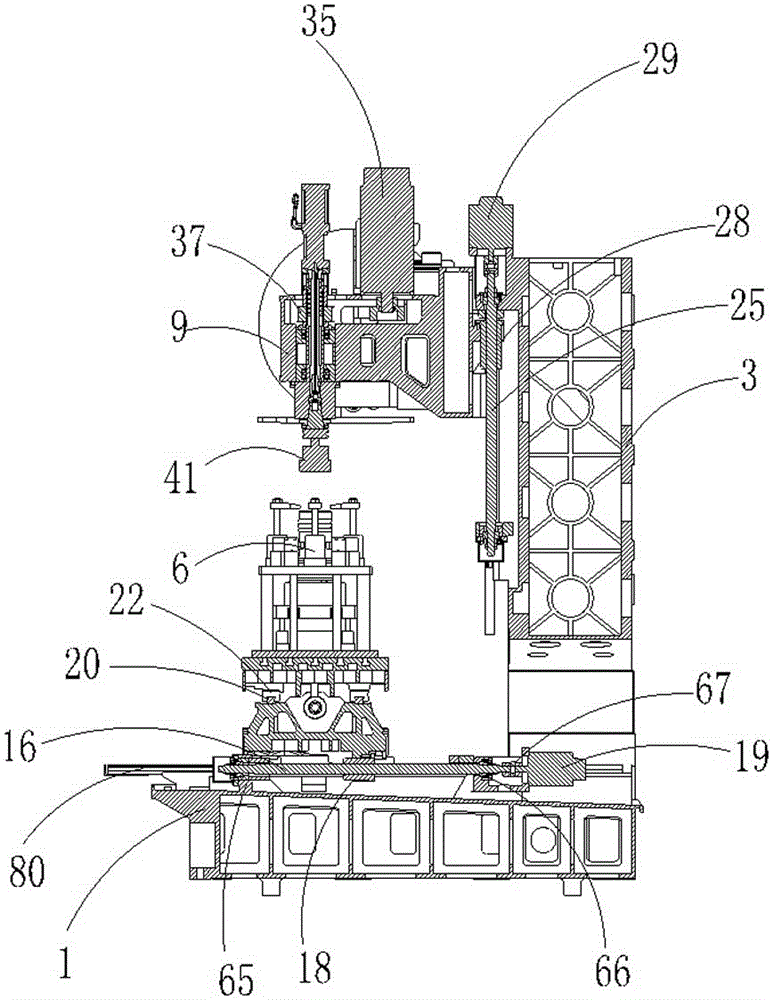

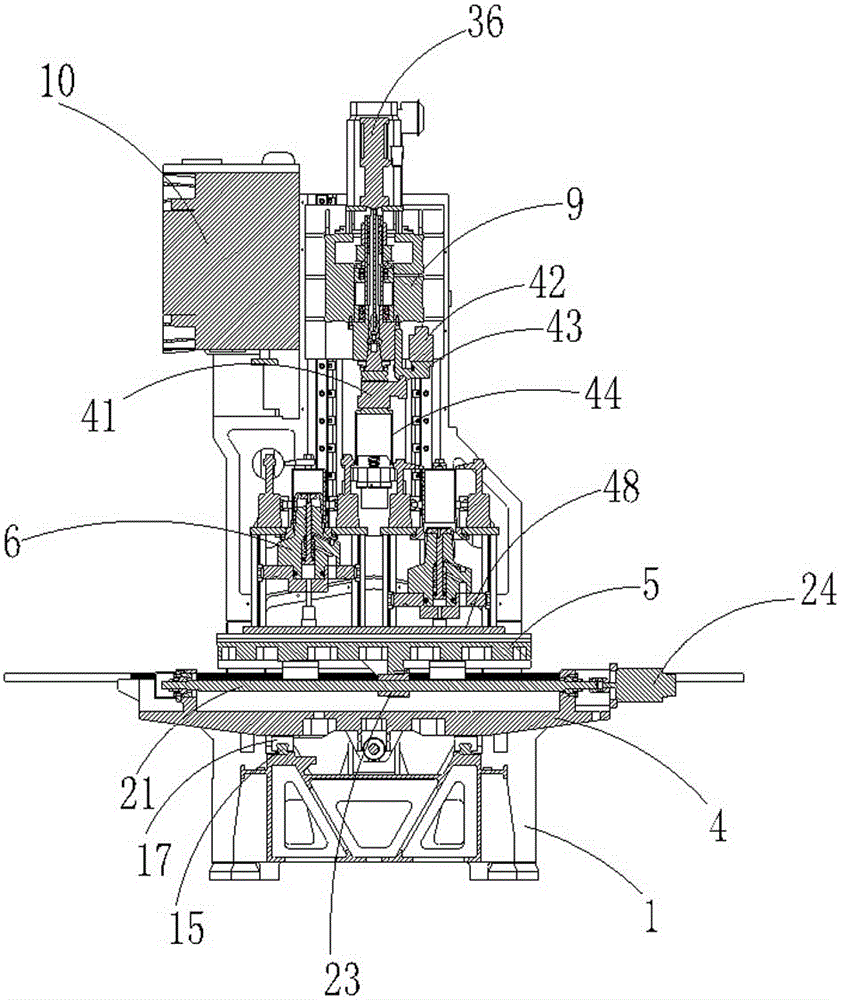

[0059] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a high-efficiency automatic numerical control machining center machine tool includes a base 1 and a hydraulic station 2, the side end of the base 1 is provided with a column 3, the upper part of the base 1 is provided with a saddle 4, and the The upper part of the saddle 4 is provided with a workbench 5, and the upper part of the described workbench 5 is provided with at least one clamp operating mechanism 6, and the described saddle 4 slides forward and backward along the base 1 through the workbench front and rear sliding mechanism 7, and the described The worktable 5 slides left and right along the saddle 4 through the workbench left and right sliding mechanism 8; the outer wall of the column 3 is provided with a spindle box 9 and a hydraulic tool magazine 10, and the described spindle box 9 and the hydraulic tool magazine 10 are in a transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com