A binding data sealing machine for file management

A file management and sealing machine technology, applied in book binding, adhesive for binding, compound continuous process of book processing, etc., can solve the problem of scalding hands, and do not cover any objects on it; Please make a piece of white paper first, the effect of plastic sealing will be better; please turn off the power switch of the machine when not in use, and unplug the plug at the same time; flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

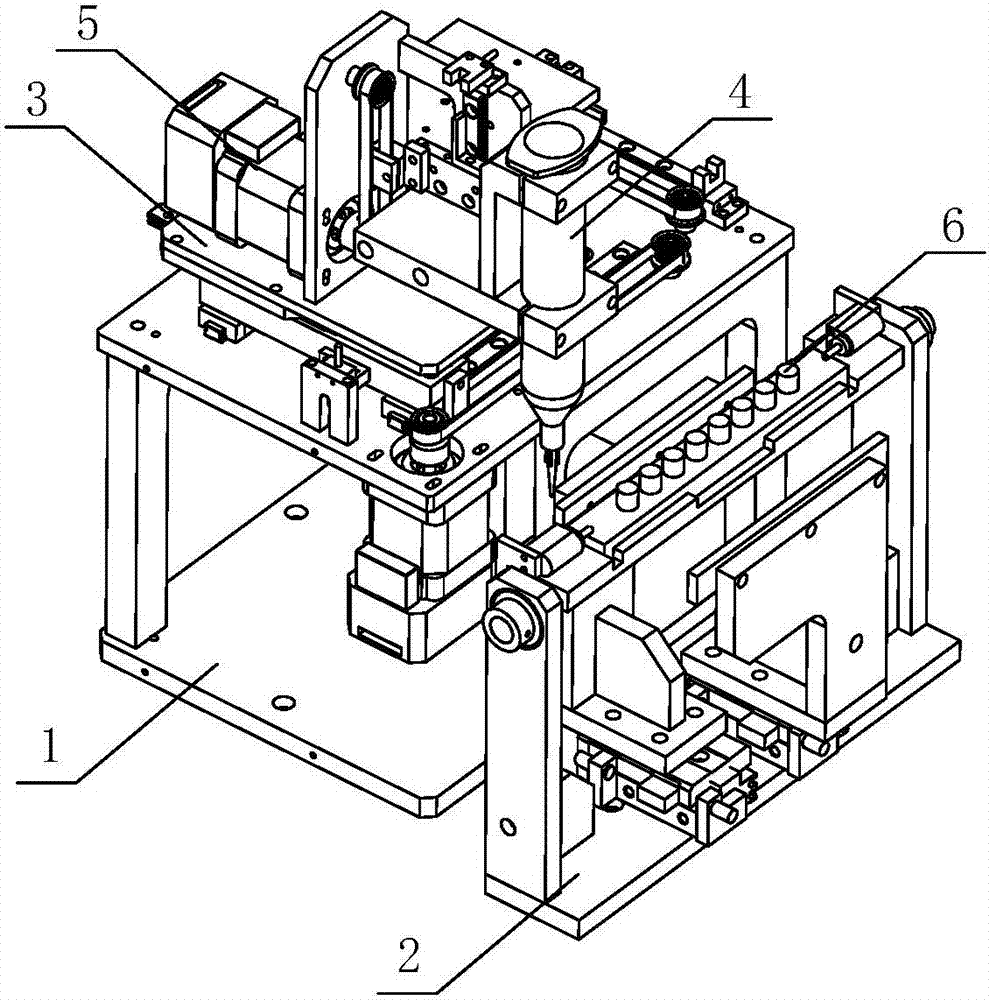

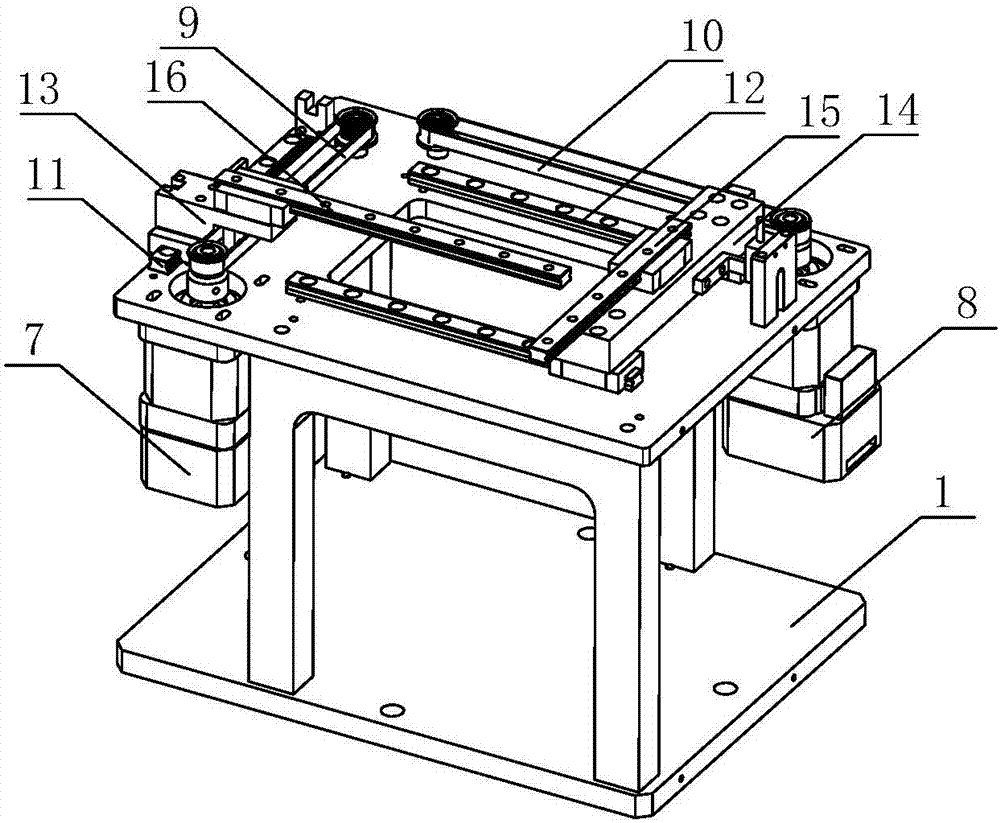

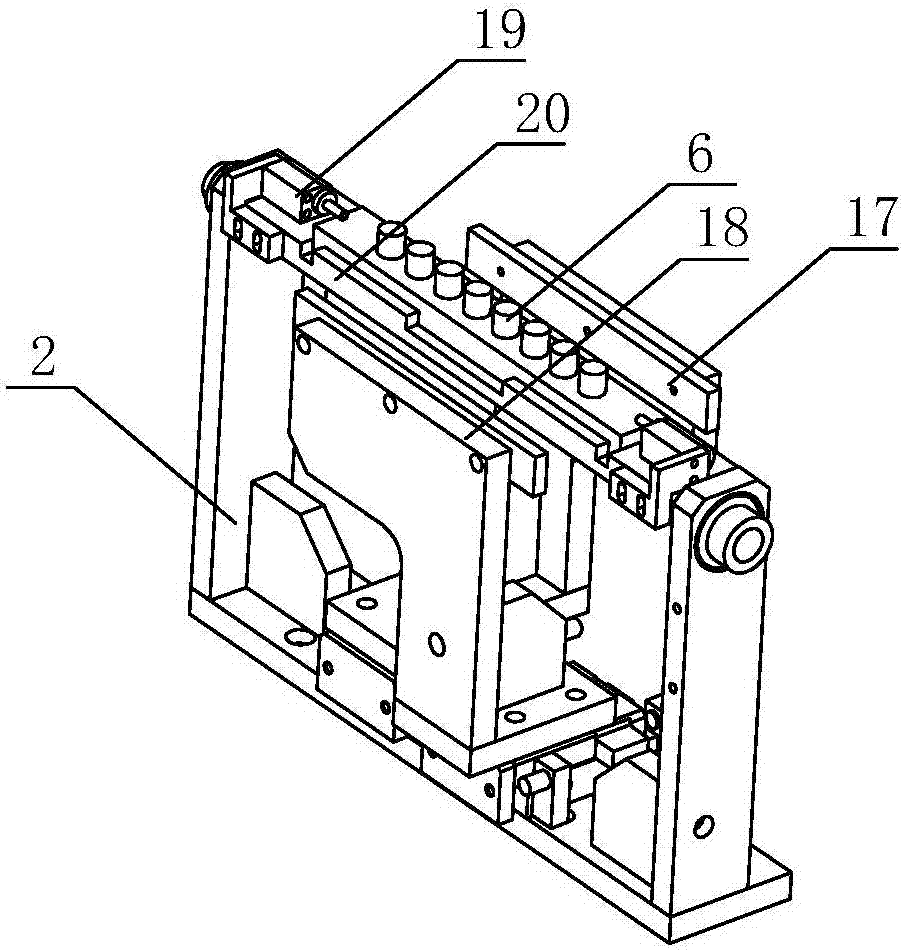

[0022] Embodiment: a binding material sealing machine for file management, its main structure includes: main base platform 1, auxiliary base platform 2, base plate 3, thermal glue tube 4, stepping motor a5, binding hole position tube 6. Stepping motor b7, stepping motor c8, track turning mechanism a9, track turning mechanism b10, base guide rail a11, base guide rail b12, rail base a13, rail base b14, floor rail a15 , Bottom plate rail b16, left-wing shelf plate 17, right-wing shelf plate 18, clamping air rod 19, sealant bracket bar 20, rubber hose platform 21, glue needle 22, track turning mechanism c23, base guide rail bar c24, guide rail Base c25, stepping motor b7 and stepping motor c8 are respectively arranged under the diagonal position on the main base platform 1;

[0023] The stepper motor b7 is provided with a track turning mechanism a9, the track base a13 is clamped on the track of the track turning mechanism a9, the bottom end of the track base a13 is slidably fixed ...

Embodiment approach 1

[0035] Possible implementation option 1: one side is punched and then glued into the package.

[0036] After sorting out the files and materials, punch holes on one side according to the spacing of the binding hole tubes 6, and the hole diameter of the holes is twice that of the binding hole tubes 6. 6, start the clamping air bar 19 so that the bound archives are in the clamped state. Adjust the position of the left-wing shelving board 17 or the right-wing shelving board 18 so that the bound archives are in a flat state.

[0037] Start the stepping motor b7 and the stepping motor c8, thereby adjusting the positions of the bottom rail a15 and the bottom rail b16, so that the equipment on the base plate 3 can be moved to the corresponding position. Put the hot melt gun with the glue stick upside down in the hot glue tube 4 , and the heated hot melt glue goes down through the glue needle 22 to produce filaments (viscous droplets). At this time, the stepping motor a5 is started,...

Embodiment approach 2

[0039] Possible implementation Option 2: Dispensing packaging after punching holes in the middle.

[0040] Glue dispensing packaging after punching in the middle is a half-fold packaging technology. In the implementation process, except that the punching of the bound archives is in the middle position, the other pre-order steps are the same as the first solution. In the last step, it is implemented like this: when the movement and glue dispensing are completed, after the hot melt adhesive is absorbed and fixed on the inner wall of the bound file hole, the binding hole tube 6 is retracted before the hot melt adhesive cools down. After shelling, the archives are folded in half, and the binding is completed after the hot melt adhesive is cooled.

[0041]The present invention is a newly designed way of binding archives and materials. The traditional binding of archives and materials adopts wire binding. This way of binding takes time, and most of them are bound manually, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com