Temperature rising furnace of runner flashboard of float glass production line, and temperature rising and exchange method

A float glass and replacement method technology, which is applied in the direction of the feeding trough, etc., can solve the problems of economic loss, large temperature fluctuation of the gate 101 to be put in, and prolonging the replacement time of the gate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

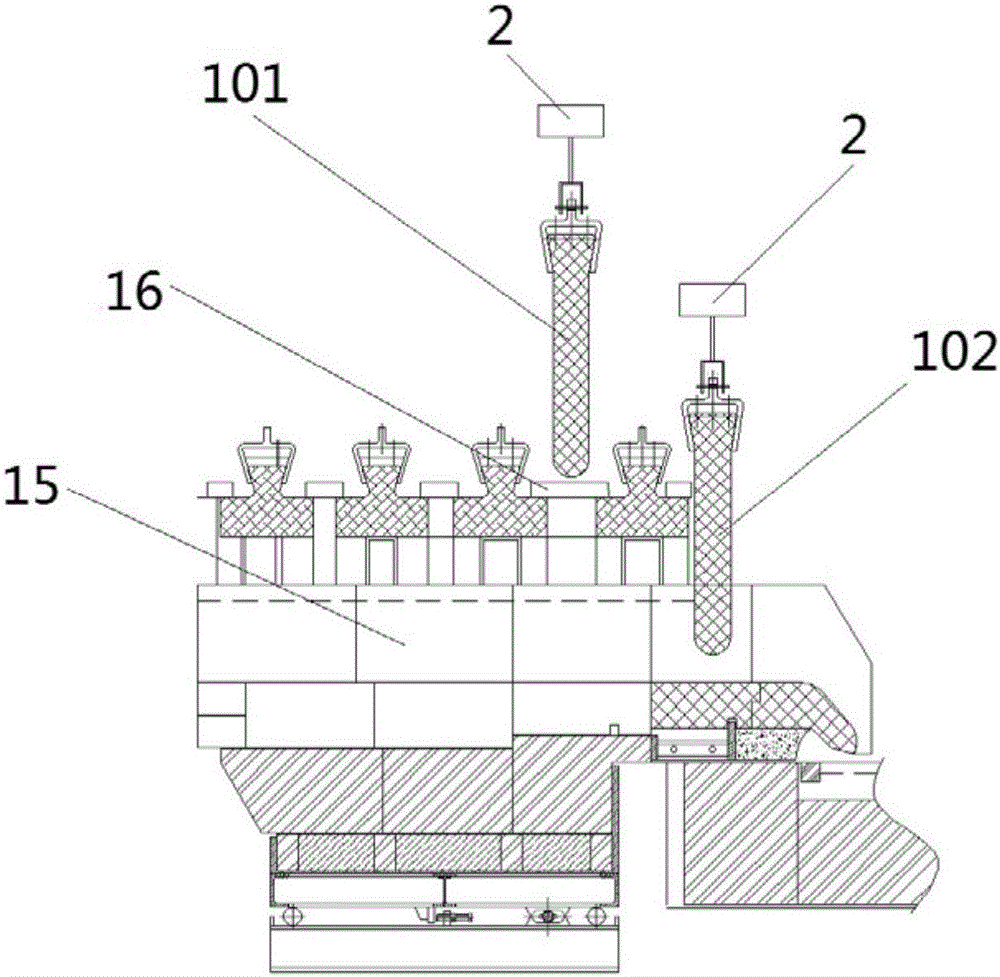

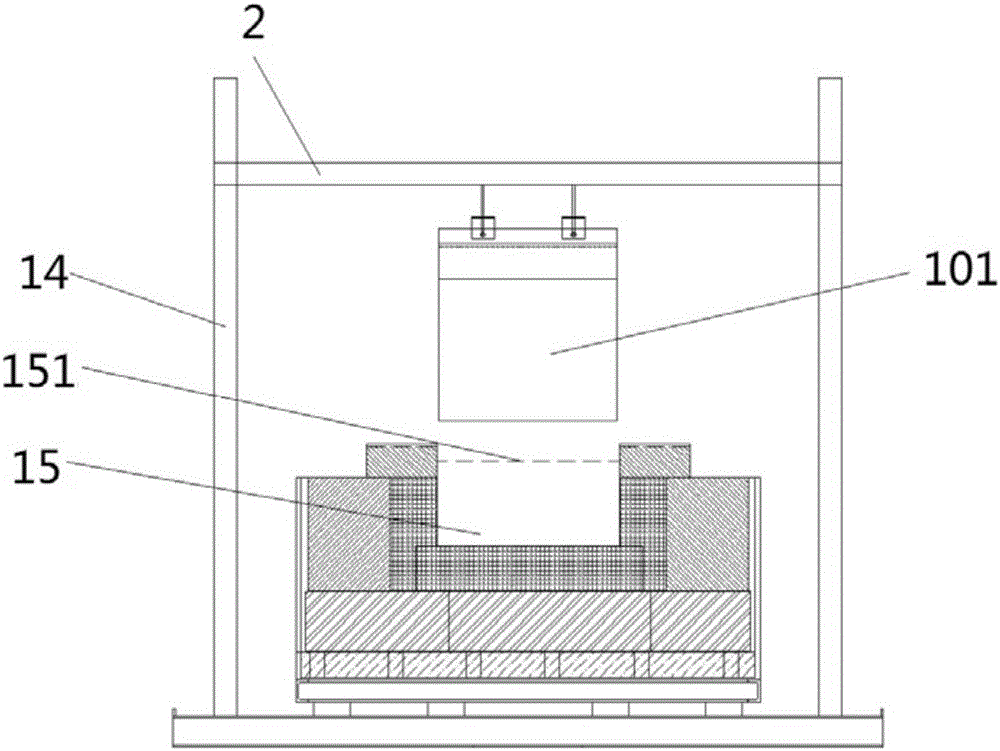

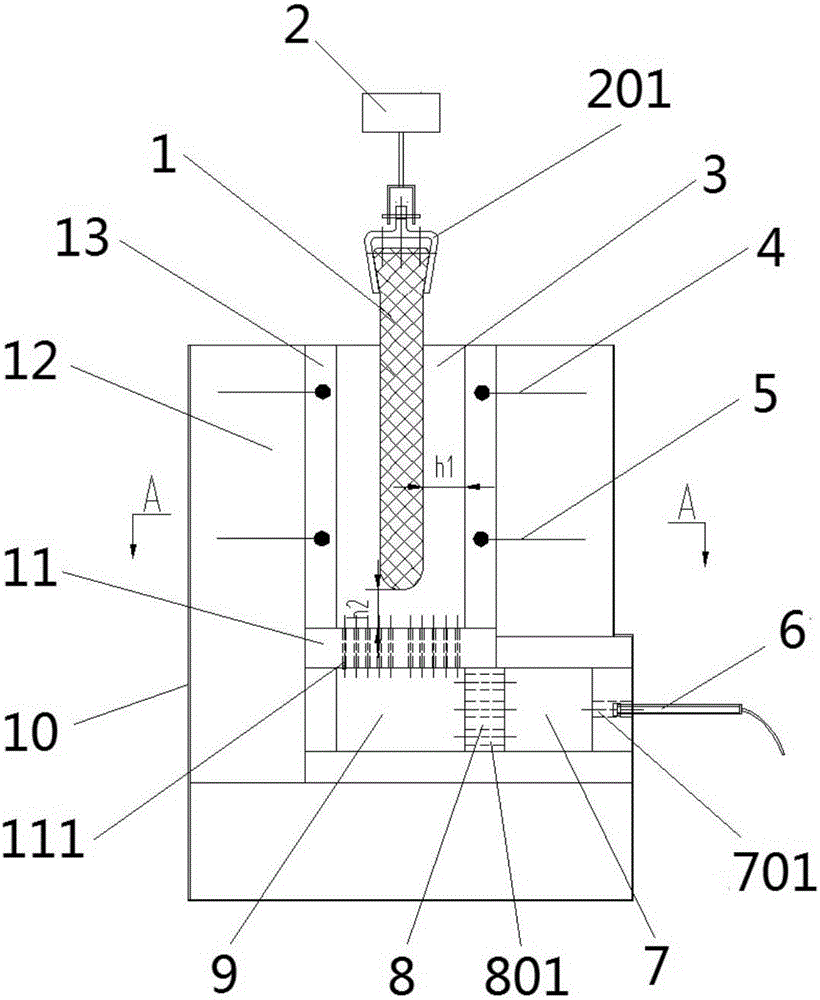

[0052] According to one aspect of the present invention, there is provided a heating furnace for the flow channel gate plate of a float glass production line, see image 3 and Figure 4 , the inside of the heating furnace includes: a ram cavity 3, which is used to accommodate at least a part of the ram 1 to be heated, and when the ram 1 to be heated is accommodated in the ram cavity 3, the ram cavity 3 The inner wall of the ram 1 to be heated will be spaced from each other; the heating part, which can heat the ram chamber 3 to raise the temperature of the ram 1 to be heated inside the ram chamber 3; and the temperature sensing unit, which senses the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com