Tearable spray film and preparation method thereof

A technology of spraying film and dimethyl ether, applied in the direction of coating, unspecified rubber coating, etc., can solve the problem of large area peeling that is not easy to form, strong corrosion of substrate or original paint, inconvenient removal of paint film, etc. problem, to achieve the effect of convenient and simple construction, fine pigment particles, uniform and smooth coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

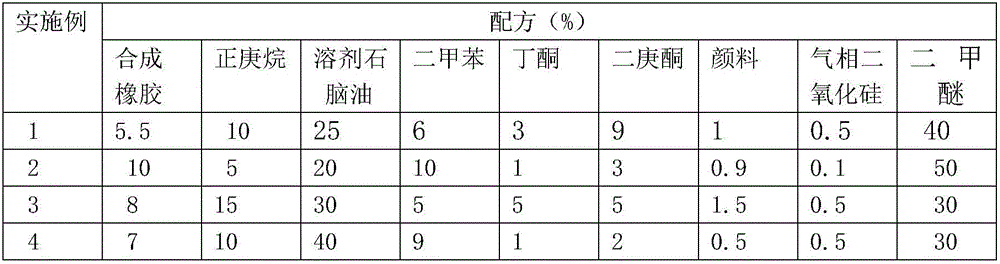

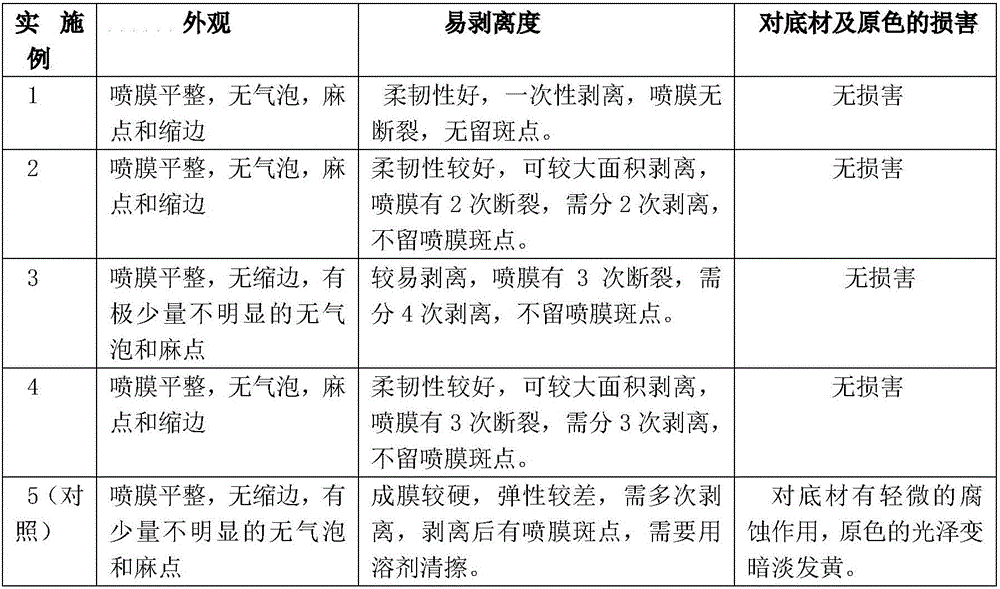

[0022] The present invention will be further described below in conjunction with specific examples.

[0023] One, the preparation method of product of the present invention comprises the following steps:

[0024] 1. Dispersion: Put n-heptane and xylene into the cylinder, stir with a disperser, and add synthetic rubber while stirring until the solution is clear and transparent; continue to add gas phase silica and pigments while stirring, and increase the speed of the disperser to Disperse at 2000 rpm for 30 minutes and then move to the grinding area for grinding.

[0025] 2. Grinding: Use a grinder to grind the color paste several times until the fineness is qualified. During the grinding process, the temperature of the color paste is controlled at 50-60°C, and ≥75°C is not allowed.

[0026] 3. Dilution: Throw the milled color paste into the remaining component solvents to dilute, then disperse evenly with a disperser, adjust the viscosity of the material liquid to a qualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com