A fixed-point vacuum ultrasonic non-destructive washing machine and its method

A vacuum ultrasonic and washing machine technology, applied to other washing machines, oscillating washing machines, washing devices, etc., can solve the problems of constant temperature heating of washing water, high cost, poor cleaning effect reflection, etc., to reduce dissolved gas content and enhance cavitation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

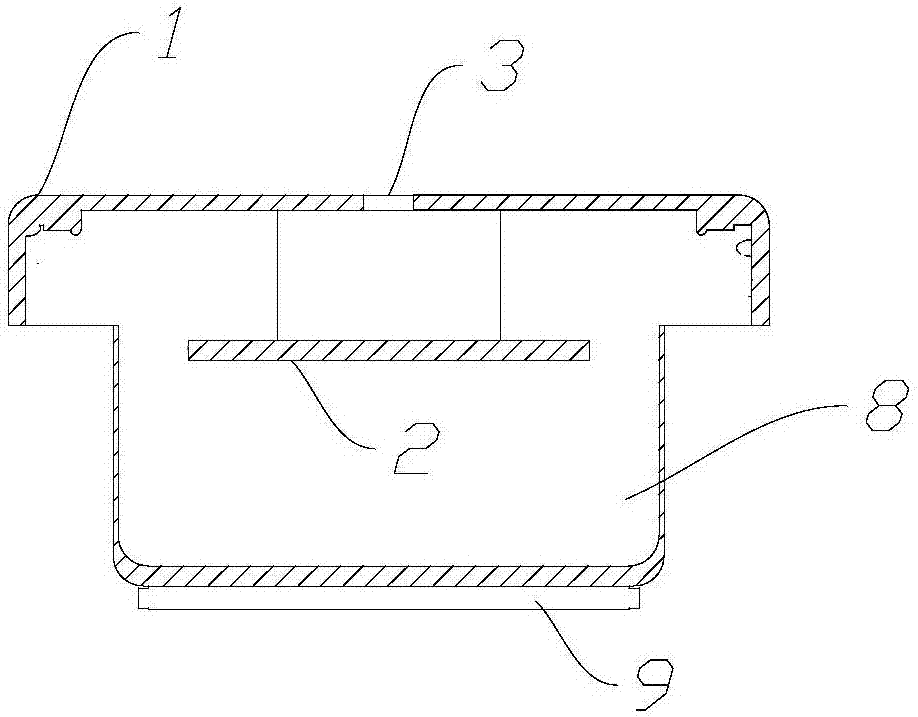

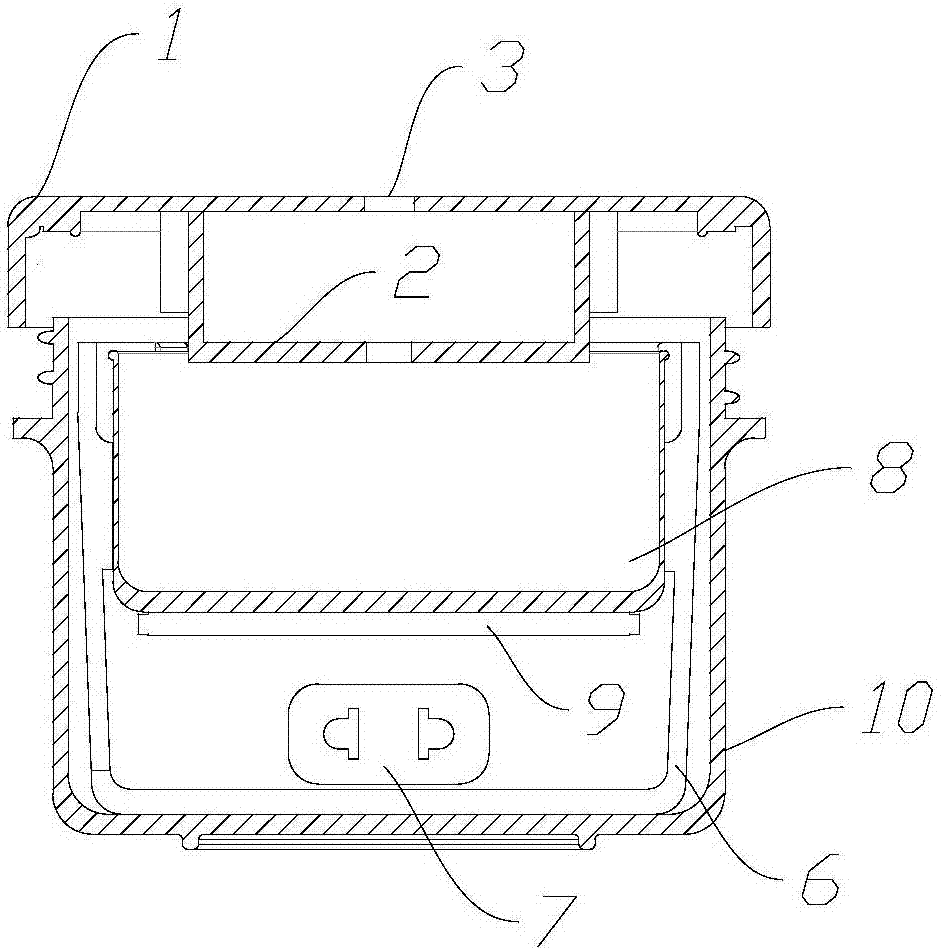

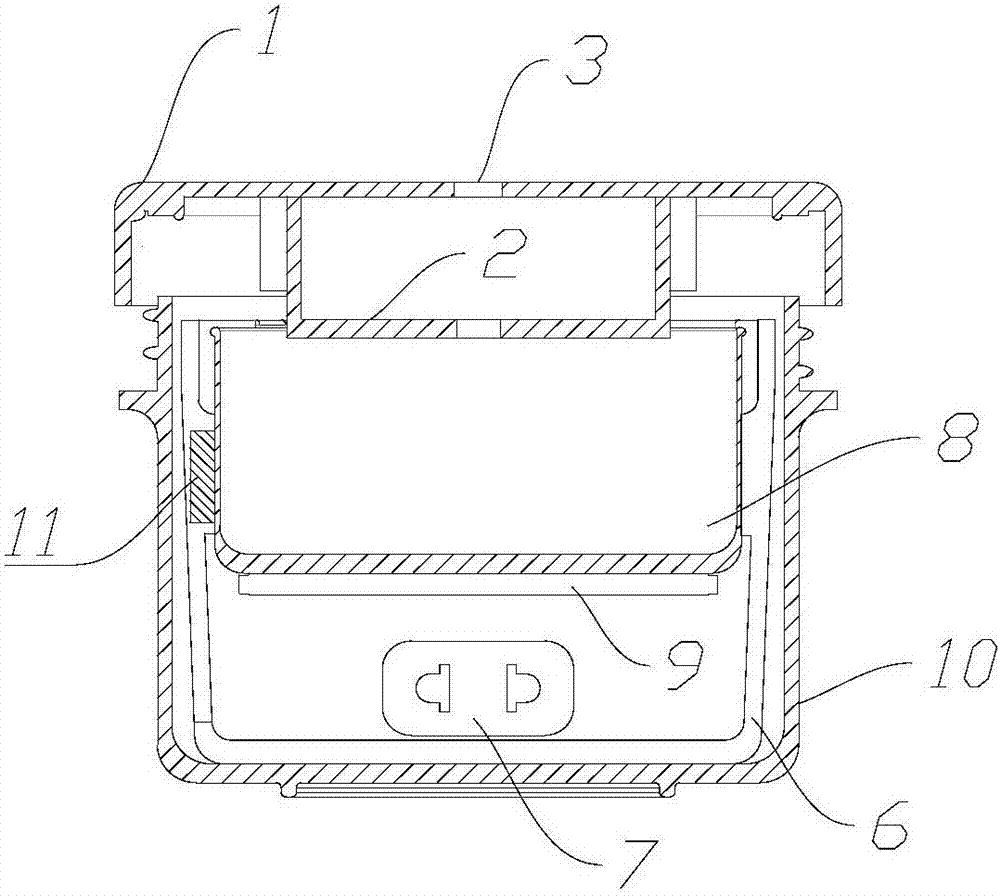

[0039] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0040] The basic steps of the fixed-point vacuum ultrasonic non-destructive laundry method of the present invention are as follows: first, place the washing water that removes the gas in the water into the washing room, then place the stained part of the clothes to be washed in the washing water, and use an ultrasonic transducer An ultrasonic field is formed in the washing room to remove stains; in the process of stain removal, it is preferable to heat the washing water, and it is further preferable to use a reflecting plate to press down the part of the clothes to be washed so that it can be stretched and at the same time to gather the ultrasonic field Near the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com