A kind of modified silk fiber with high hygroscopicity and moisture retention and preparation method thereof

A silk fiber, high hygroscopic technology, applied in the field of textile materials, can solve the problem of limited water absorption, achieve the effects of excellent hygroscopicity, repair damage, improve water washability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

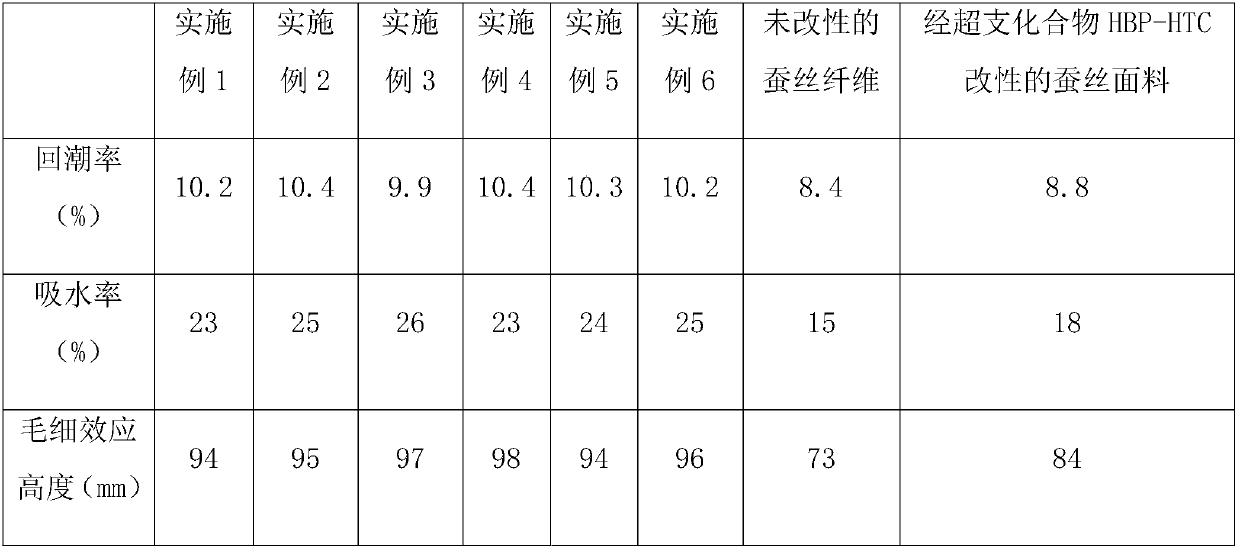

Examples

Embodiment 1

[0026] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 2%, and it is swelled at 70°C for 5 minutes, and then the swollen silk fiber is kneaded and carded to obtain a fibrillation degree of 20%. of silk fibers.

[0027] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 85% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 5 parts of molecular weight chitosan, 3 parts of sodium alginate, 2 parts of corn starch, 1 part of honeysuckle and 50 parts of deionized water.

[0028] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 25° C. to completely wet them, taken out, dried at 60° C., and then Immerse in the silk fibroin ...

Embodiment 2

[0030] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 4%, and it is swelled at 80°C for 15 minutes, and then the swollen silk fiber is rubbed and carded to obtain a fibrillation degree of 35%. of silk fibers.

[0031] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 95% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 15 parts of chitosan with molecular weight, 7 parts of sodium alginate, 8 parts of corn starch, 5 parts of honeysuckle and 80 parts of deionized water.

[0032] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 30° C. to completely wet them, taken out, dried at 70° C., and then Immerse in the silk f...

Embodiment 3

[0034] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 3%, and it is swelled at 75°C for 10 minutes, and then the swollen silk fiber is kneaded and carded to obtain a fibrillation degree of 25%. of silk fibers.

[0035] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 90% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 10 parts of chitosan with molecular weight, 5 parts of sodium alginate, 4 parts of corn starch, 2 parts of honeysuckle and 60 parts of deionized water.

[0036] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 27° C. to completely wet them, taken out, dried at 65° C., and then Immerse in the silk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com